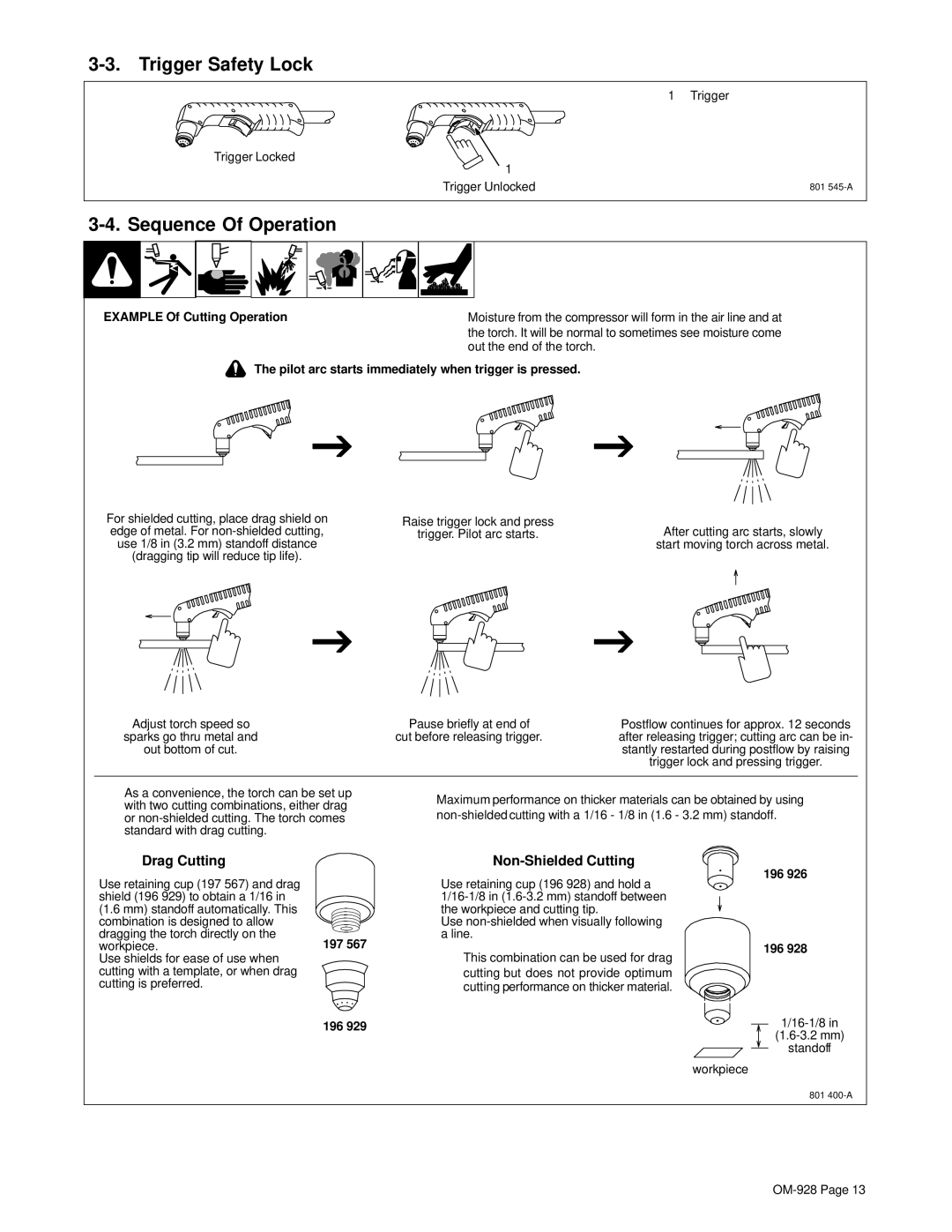

3-3. Trigger Safety Lock

1 Trigger

Trigger Locked

1 |

|

Trigger Unlocked | 801 |

3-4. Sequence Of Operation

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EXAMPLE Of Cutting Operation | . Moisture from the compressor will form in the air line and at | ||||||

|

|

|

|

|

|

| the torch. It will be normal to sometimes see moisture come |

|

|

|

|

|

|

| out the end of the torch. |

The pilot arc starts immediately when trigger is pressed.

For shielded cutting, place drag shield on edge of metal. For

Adjust torch speed so sparks go thru metal and out bottom of cut.

Raise trigger lock and press

trigger. Pilot arc starts.

Pause briefly at end of cut before releasing trigger.

After cutting arc starts, slowly start moving torch across metal.

Postflow continues for approx. 12 seconds after releasing trigger; cutting arc can be in- stantly restarted during postflow by raising trigger lock and pressing trigger.

As a convenience, the torch can be set up with two cutting combinations, either drag or

.Maximum performance on thicker materials can be obtained by using

Drag Cutting

Use retaining cup (197 567) and drag shield (196 929) to obtain a 1/16 in (1.6 mm) standoff automatically. This combination is designed to allow dragging the torch directly on the workpiece.

Use shields for ease of use when cutting with a template, or when drag cutting is preferred.

Non-Shielded Cutting

196 926

Use retaining cup (196 928) and hold a

Use

197 567 | 196 928 |

| . This combination can be used for drag |

| cutting but does not provide optimum |

| cutting performance on thicker material. |

196 929 |

standoff

workpiece

801