Connecting the outside lines.

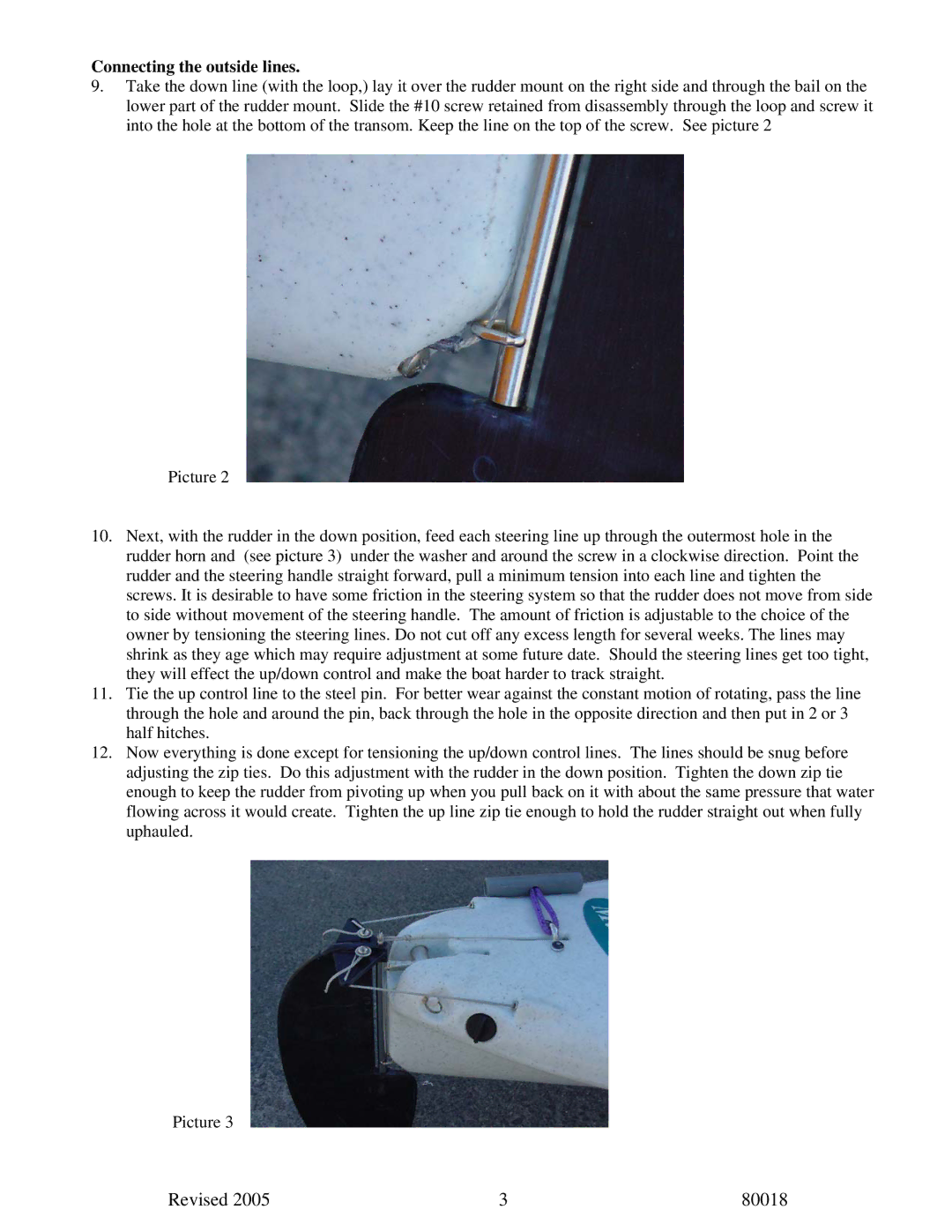

9.Take the down line (with the loop,) lay it over the rudder mount on the right side and through the bail on the lower part of the rudder mount. Slide the #10 screw retained from disassembly through the loop and screw it into the hole at the bottom of the transom. Keep the line on the top of the screw. See picture 2

Picture 2

10.Next, with the rudder in the down position, feed each steering line up through the outermost hole in the rudder horn and (see picture 3) under the washer and around the screw in a clockwise direction. Point the rudder and the steering handle straight forward, pull a minimum tension into each line and tighten the screws. It is desirable to have some friction in the steering system so that the rudder does not move from side to side without movement of the steering handle. The amount of friction is adjustable to the choice of the owner by tensioning the steering lines. Do not cut off any excess length for several weeks. The lines may shrink as they age which may require adjustment at some future date. Should the steering lines get too tight, they will effect the up/down control and make the boat harder to track straight.

11.Tie the up control line to the steel pin. For better wear against the constant motion of rotating, pass the line through the hole and around the pin, back through the hole in the opposite direction and then put in 2 or 3 half hitches.

12.Now everything is done except for tensioning the up/down control lines. The lines should be snug before adjusting the zip ties. Do this adjustment with the rudder in the down position. Tighten the down zip tie enough to keep the rudder from pivoting up when you pull back on it with about the same pressure that water flowing across it would create. Tighten the up line zip tie enough to hold the rudder straight out when fully uphauled.

Picture 3

Revised 2005 | 3 | 80018 |