ELECTRIC CHAIN SAW

CLEANING AND MAINTENANCE

NOTICE: Below are instructions for servicing your chain saw. Any servicing not mentioned below should be done by an authorized service center.

CLEANING SAW BODY

![]() WARNING: Unplug chain saw from power source before servic- ing. Severe injury or death could occur from electrical shock or body contact with moving chain.

WARNING: Unplug chain saw from power source before servic- ing. Severe injury or death could occur from electrical shock or body contact with moving chain.

![]() WARNING: Cutting edges on chain are sharp. Use protective gloves when handling chain.

WARNING: Cutting edges on chain are sharp. Use protective gloves when handling chain.

![]() WARNING: When cleaning saw body,

WARNING: When cleaning saw body,

•do not submerge saw in any liquids

•do not use products that con- tain ammonia, chlorine, or abrasives

•do not use chlorinated cleaning solvents,carbon tetrachloride, kerosene, or gasoline

Keep saw body clean. Use a soft cloth damp- ened with a mild soap and water mixture. Wipe saw body to clean.

CARE OF GUIDE BAR

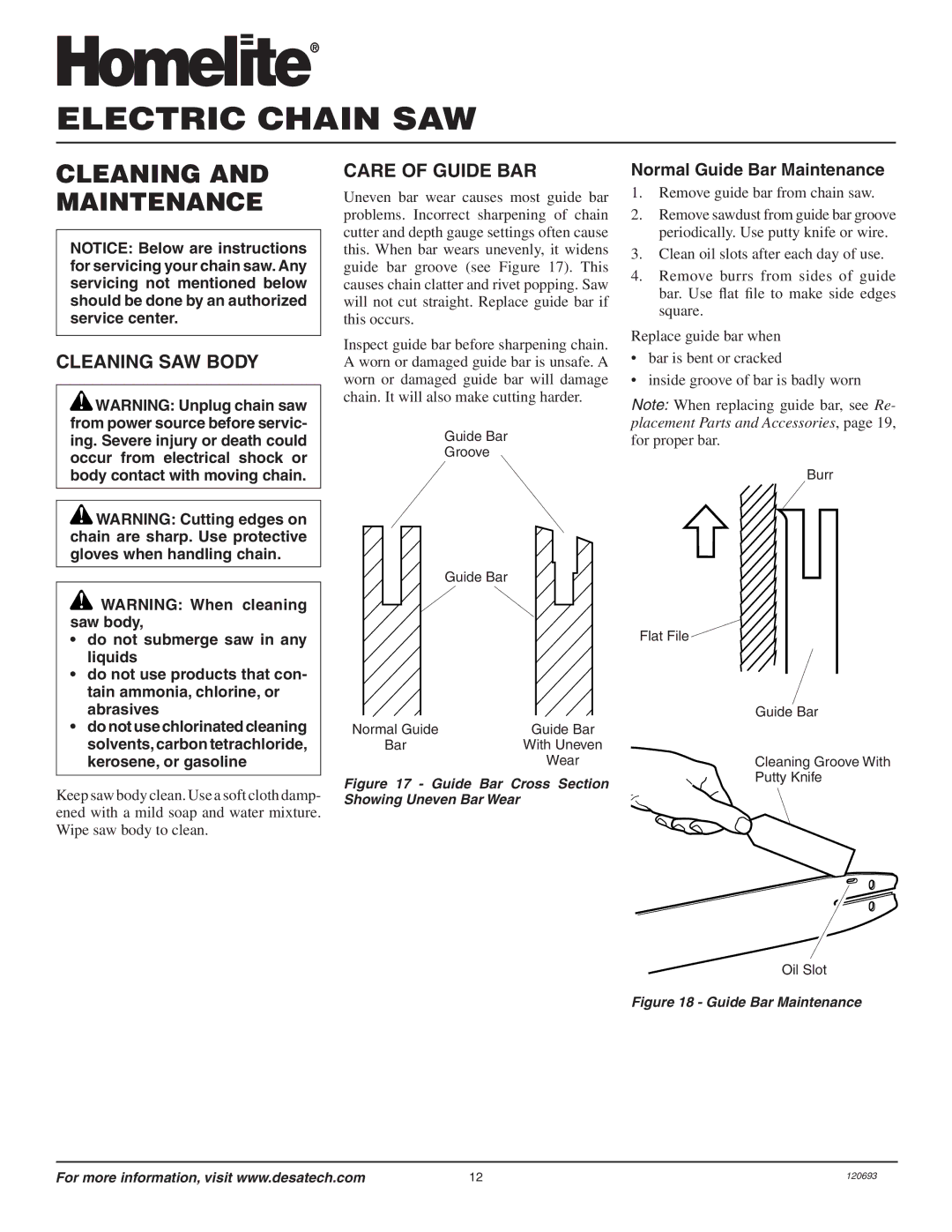

Uneven bar wear causes most guide bar problems. Incorrect sharpening of chain cutter and depth gauge settings often cause this. When bar wears unevenly, it widens guide bar groove (see Figure 17). This causes chain clatter and rivet popping. Saw will not cut straight. Replace guide bar if this occurs.

Inspect guide bar before sharpening chain. A worn or damaged guide bar is unsafe. A worn or damaged guide bar will damage chain. It will also make cutting harder.

Guide Bar

Groove

Guide Bar

Normal Guide | Guide Bar |

Bar | With Uneven |

| Wear |

Figure 17 - Guide Bar Cross Section Showing Uneven Bar Wear

Normal Guide Bar Maintenance

1.Remove guide bar from chain saw.

2.Remove sawdust from guide bar groove periodically. Use putty knife or wire.

3.Clean oil slots after each day of use.

4.Remove burrs from sides of guide bar. Use flat file to make side edges square.

Replace guide bar when

•bar is bent or cracked

•inside groove of bar is badly worn

Note: When replacing guide bar, see Re- placement Parts and Accessories, page 19, for proper bar.

Burr

Flat File ![]()

Guide Bar

Cleaning Groove With

Putty Knife

Oil Slot

Figure 18 - Guide Bar Maintenance

For more information, visit www.desatech.com | 12 | 120693 |