V8043A,E,F 5000 Series

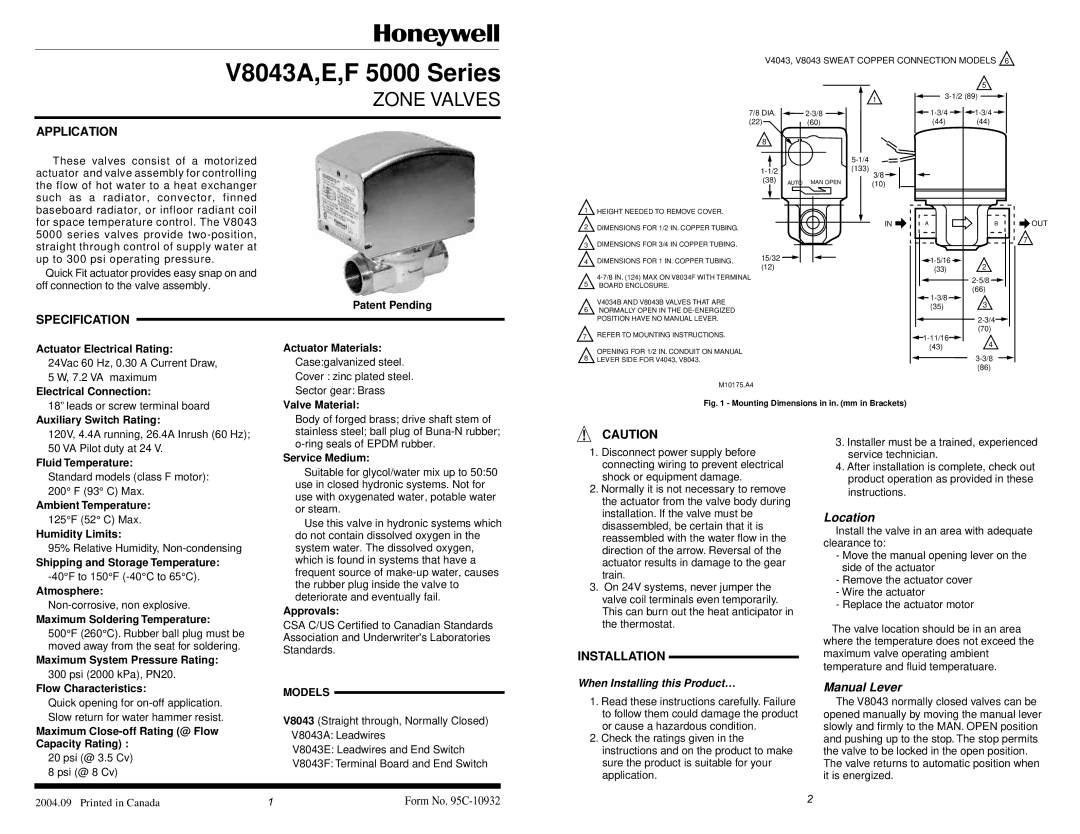

V4043, V8043 SWEAT COPPER CONNECTION MODELS 6

ZONE VALVES

APPLICATION

These valves consist of a motorized actuator and valve assembly for controlling the flow of hot water to a heat exchanger such as a radiator, convector, finned baseboard radiator, or infloor radiant coil for space temperature control. The V8043 5000 series valves provide

Quick Fit actuator provides easy snap on and off connection to the valve assembly.

Patent Pending

7/8 DIA. |

| |

(22) |

| (60) |

8 |

|

|

|

| |

(38) | AUTO | MAN OPEN |

|

1HEIGHT NEEDED TO REMOVE COVER.

2DIMENSIONS FOR 1/2 IN. COPPER TUBING.

3DIMENSIONS FOR 3/4 IN COPPER TUBING.

4 | DIMENSIONS FOR 1 IN. COPPER TUBING. | 15/32 | |

(12) | |||

|

| ||

5 |

| ||

BOARD ENCLOSURE. |

|

V4034B AND V8043B VALVES THAT ARE |

6 NORMALLY OPEN IN THE |

5

1![]()

![]()

![]()

![]()

![]() 1-3/4

1-3/4![]()

(44)(44)

(133)

3/8 |

|

|

|

(10) |

|

|

|

IN | A |

| B |

|

| 2 | |

|

| (33) | |

|

|

|

![]()

(66)

3 | |

(35) |

![]() OUT

OUT

7

SPECIFICATION

Actuator Electrical Rating:

24Vac 60 Hz, 0.30 A Current Draw, 5 W, 7.2 VA maximum

Actuator Materials:

Case:galvanized steel. Cover : zinc plated steel.

| POSITION HAVE NO MANUAL LEVER. |

7 | REFER TO MOUNTING INSTRUCTIONS. |

8 | OPENING FOR 1/2 IN. CONDUIT ON MANUAL |

LEVER SIDE FOR V4043, V8043. |

![]()

![]()

![]() 1-11/16

1-11/16![]()

(43)4

(86)

Electrical Connection:

18” leads or screw terminal board

Auxiliary Switch Rating:

Sector gear: Brass

Valve Material:

Body of forged brass; drive shaft stem of

M10175.A4

Fig. 1 - Mounting Dimensions in in. (mm in Brackets)

120V, 4.4A running, 26.4A Inrush (60 Hz); 50 VA Pilot duty at 24 V.

Fluid Temperature:

Standard models (class F motor): 200° F (93° C) Max.

Ambient Temperature:

125°F (52° C) Max.

Humidity Limits:

95% Relative Humidity,

Shipping and Storage Temperature:

Atmosphere:

Maximum Soldering Temperature:

500°F (260°C). Rubber ball plug must be moved away from the seat for soldering.

Maximum System Pressure Rating:

300 psi (2000 kPa), PN20.

Flow Characteristics:

Quick opening for

Slow return for water hammer resist.

Maximum Close-off Rating (@ Flow Capacity Rating) :

20 psi (@ 3.5 Cv)

8 psi (@ 8 Cv)

stainless steel; ball plug of

Service Medium:

Suitable for glycol/water mix up to 50:50 use in closed hydronic systems. Not for use with oxygenated water, potable water or steam.

Use this valve in hydronic systems which do not contain dissolved oxygen in the system water. The dissolved oxygen, which is found in systems that have a frequent source of

Approvals:

CSA C/US Certified to Canadian Standards Association and Underwriter's Laboratories Standards.

MODELS

V8043 (Straight through, Normally Closed)

V8043A: Leadwires

V8043E: Leadwires and End Switch

V8043F: Terminal Board and End Switch

CAUTION

1.Disconnect power supply before connecting wiring to prevent electrical shock or equipment damage.

2.Normally it is not necessary to remove the actuator from the valve body during installation. If the valve must be disassembled, be certain that it is reassembled with the water flow in the direction of the arrow. Reversal of the actuator results in damage to the gear train.

3.On 24V systems, never jumper the valve coil terminals even temporarily. This can burn out the heat anticipator in the thermostat.

INSTALLATION

When Installing this Product…

1.Read these instructions carefully. Failure to follow them could damage the product or cause a hazardous condition.

2.Check the ratings given in the instructions and on the product to make sure the product is suitable for your application.

3.Installer must be a trained, experienced service technician.

4.After installation is complete, check out product operation as provided in these instructions.

Location

Install the valve in an area with adequate clearance to:

-Move the manual opening lever on the side of the actuator

-Remove the actuator cover

-Wire the actuator

-Replace the actuator motor

The valve location should be in an area where the temperature does not exceed the maximum valve operating ambient temperature and fluid temperatuare.

Manual Lever

The V8043 normally closed valves can be opened manually by moving the manual lever slowly and firmly to the MAN. OPEN position and pushing up to the stop. The stop permits the valve to be locked in the open position.

The valve returns to automatic position when it is energized.

2004.09 Printed in Canada | 1 | Form No. |

2