APOLLO 60 HP | Page 3 | ||

|

|

|

|

This manual does not contain all the health and safety requirements regarding toxic and hazard- ous dust exposure. Obtain copies of the OSHA regulations and consult a safety professional and/or industrial hygienist for complete require- ments.

Within this manual we refer to hazardous or con- taminated environments. These environments can be any place around the blast area that could contain toxic or hazardous dust.

If these warnings are not completely understood, or if further information is required, contact a local OSHA office. If any personnel in the abra- sive blasting vicinity cannot read or comprehend these warnings and the entire content of this instructional material, assign a qualified person to instruct them.

Additional information on abrasive blasting haz- ards titled “Preventing Silicosis and Death From Sandblasting”, Publication No.

Publications Dissemination, DSDTT

National Institute for Occupational Safety and Health

4676 Columbia Parkway

Cincinnati, OH 45226 (513)

1.4Cautions and Limitations

1.4.1Not for use in atmospheres immediately danger- ous to life or health.

1.4.2Do not exceed maximum use concentrations es- tablished by regulatory standards.

1.4.3

1.4.4Use only the pressure ranges and hose lengths specified in the instruction manual.

1.4.5Failure to properly use and maintain this product could result in injury or death.

1.4.6All approved respirators shall be selected, fitted, used, and maintained in accordance with MSHA, OSHA, and other applicable regulations.

1.4.7Never substitute, modify, add, or omit parts. Use only exact replacement parts in the configuration as speci- fied by the manufacturer.

1.4.8Refer to users instructions, and/or maintenance manuals for information on use and maintenance of these respirators.

1.5Special Use Limitations

1.5.1Air pressure at the point of attachment (the point of attachment is where the respirator supply hose is connected to the respirable air source) must be main- tained at pressures between the minimum pressure as shown in the table in Section 4.2.4 and the maximum of 100 psi.

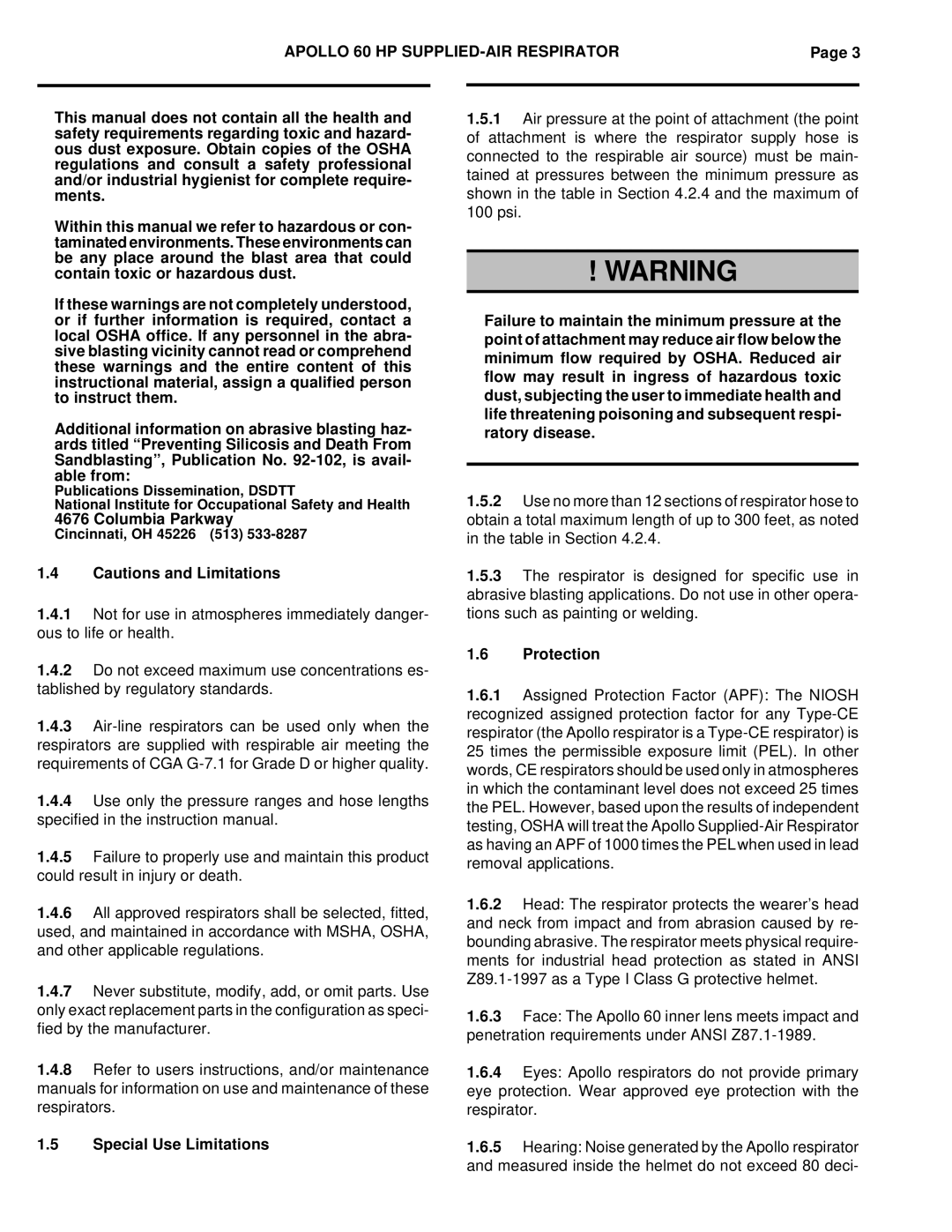

! WARNING

Failure to maintain the minimum pressure at the point of attachment may reduce air flow below the minimum flow required by OSHA. Reduced air flow may result in ingress of hazardous toxic dust, subjecting the user to immediate health and life threatening poisoning and subsequent respi- ratory disease.

1.5.2Use no more than 12 sections of respirator hose to obtain a total maximum length of up to 300 feet, as noted in the table in Section 4.2.4.

1.5.3The respirator is designed for specific use in abrasive blasting applications. Do not use in other opera- tions such as painting or welding.

1.6Protection

1.6.1Assigned Protection Factor (APF): The NIOSH recognized assigned protection factor for any

1.6.2Head: The respirator protects the wearer’s head and neck from impact and from abrasion caused by re- bounding abrasive. The respirator meets physical require- ments for industrial head protection as stated in ANSI

1.6.3Face: The Apollo 60 inner lens meets impact and penetration requirements under ANSI

1.6.4Eyes: Apollo respirators do not provide primary eye protection. Wear approved eye protection with the respirator.

1.6.5Hearing: Noise generated by the Apollo respirator and measured inside the helmet do not exceed 80 deci-