APOLLO 60 HP | Page 7 | ||

|

|

|

|

monoxide removal or conversion system may also be used to ensure breathing air quality. The maximum allowable presence of carbon monoxide in Grade D breathing air is 10 parts per million (ppm).

4.2Air Volume and Pressure

4.2.1A pressure regulator and gauge must be installed at the point where the respirator hose is attached to the air source. The Clemco CPF Filter with regulator meets this requirement if the inlet pressure does not exceed 125 psi. See typical installation, Figure 1.

! DANGER

Do not connect the Apollo Respirator or CPF Filter, or any other regulator or filter, to bottled air that does not have a pressure reducing valve that reduces pressure to maximum of 125 psi (65 to 100 psi for the respirator only). Failure to comply with this warning will cause devices rated at lower pressures to explode under the high pres- sure of bottled air. Such an explosion could cause severe injury or death.

4.2.2The respirator must be supplied with 15 cfm (cubic feet per minute) of Grade D breathing air at 65 to 100 psi (pounds per square inch). When using an alternate Cool- Air Tube or Climate Control Tube, the respirator must be supplied with 20 cfm of Grade D breathing air at 90 to 100 psi.

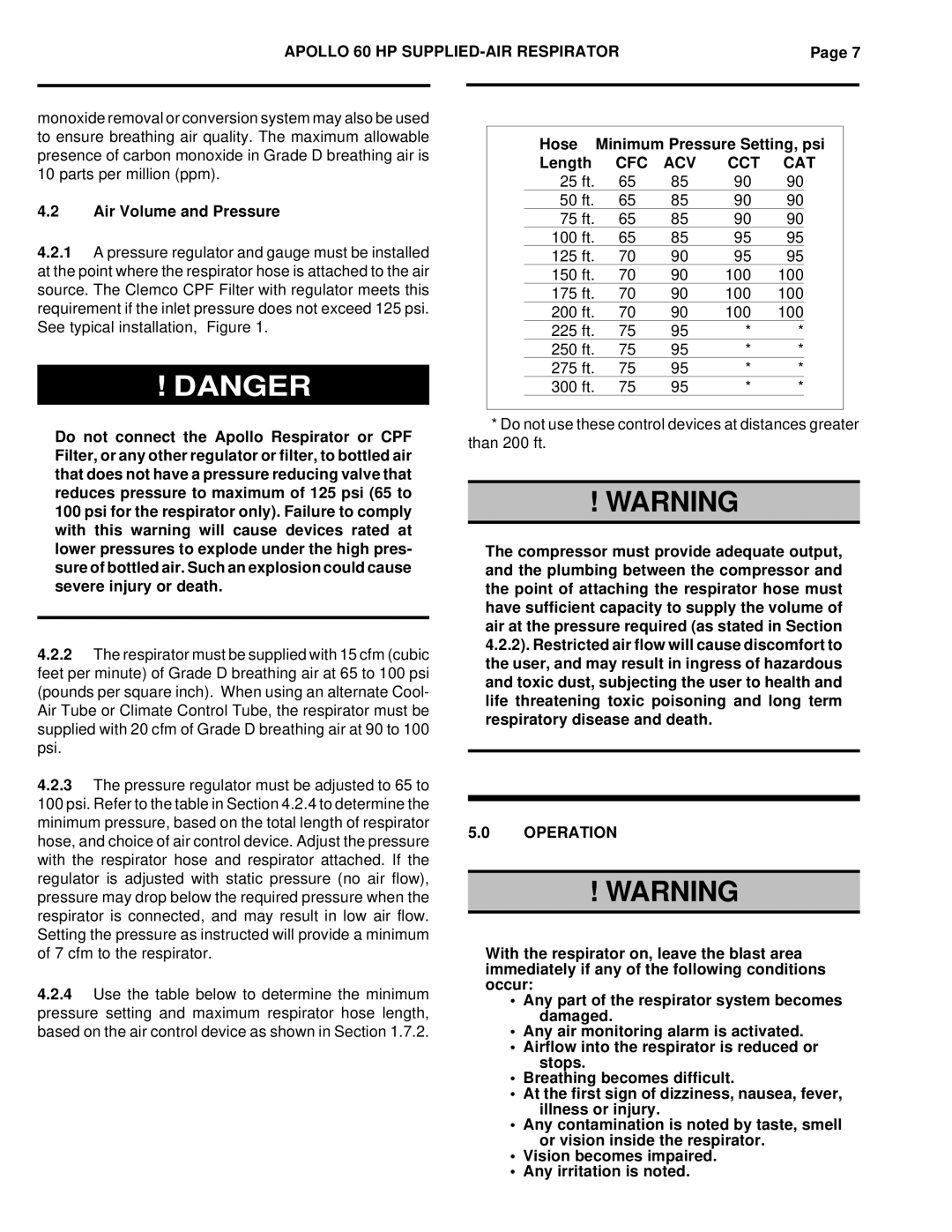

4.2.3The pressure regulator must be adjusted to 65 to 100 psi. Refer to the table in Section 4.2.4 to determine the minimum pressure, based on the total length of respirator hose, and choice of air control device. Adjust the pressure with the respirator hose and respirator attached. If the regulator is adjusted with static pressure (no air flow), pressure may drop below the required pressure when the respirator is connected, and may result in low air flow. Setting the pressure as instructed will provide a minimum of 7 cfm to the respirator.

4.2.4Use the table below to determine the minimum pressure setting and maximum respirator hose length, based on the air control device as shown in Section 1.7.2.

Hose | Minimum Pressure Setting, psi | ||||

Length | CFC | ACV | CCT | CAT | |

25 ft. | 65 | 85 | 90 | 90 |

|

50 ft. | 65 | 85 | 90 | 90 |

|

75 ft. | 65 | 85 | 90 | 90 |

|

100 ft. | 65 | 85 | 95 | 95 |

|

125 ft. | 70 | 90 | 95 | 95 |

|

150 ft. | 70 | 90 | 100 | 100 |

|

175 ft. | 70 | 90 | 100 | 100 |

|

200 ft. | 70 | 90 | 100 | 100 |

|

225 ft. | 75 | 95 | * | * |

|

250 ft. | 75 | 95 | * | * |

|

275 ft. | 75 | 95 | * | * |

|

300 ft. | 75 | 95 | * | * |

|

*Do not use these control devices at distances greater than 200 ft.

! WARNING

The compressor must provide adequate output, and the plumbing between the compressor and the point of attaching the respirator hose must have sufficient capacity to supply the volume of air at the pressure required (as stated in Section 4.2.2). Restricted air flow will cause discomfort to the user, and may result in ingress of hazardous and toxic dust, subjecting the user to health and life threatening toxic poisoning and long term respiratory disease and death.

5.0OPERATION

! WARNING

With the respirator on, leave the blast area immediately if any of the following conditions occur:

•Any part of the respirator system becomes damaged.

•Any air monitoring alarm is activated.

•Airflow into the respirator is reduced or stops.

•Breathing becomes difficult.

•At the first sign of dizziness, nausea, fever, illness or injury.

•Any contamination is noted by taste, smell or vision inside the respirator.

•Vision becomes impaired.

•Any irritation is noted.