APOLLO 60 HP | Page 9 | ||

|

|

|

|

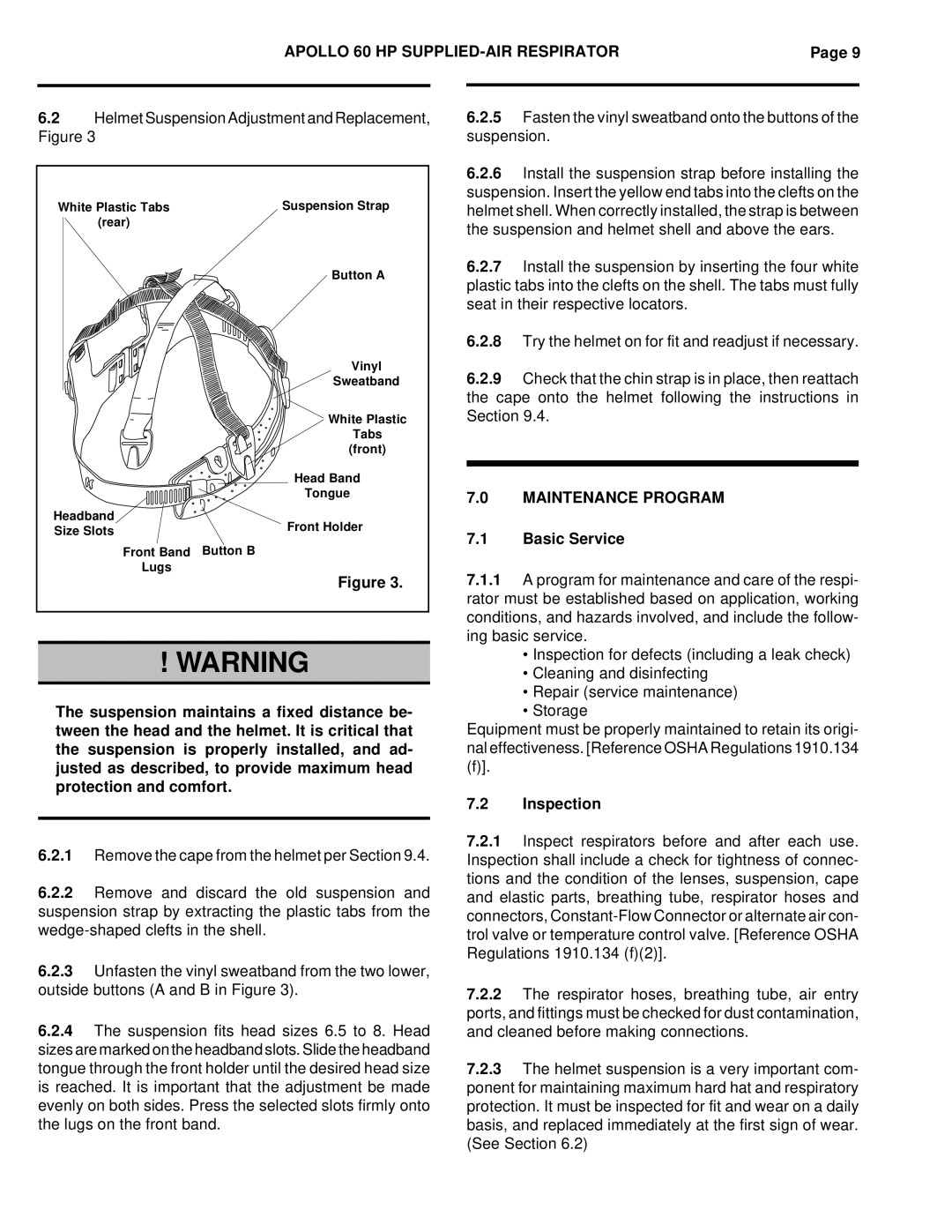

6.2Helmet Suspension Adjustment and Replacement, Figure 3

White Plastic Tabs | Suspension Strap |

(rear) |

|

| Button A |

Vinyl

Sweatband

White Plastic

Tabs (front)

Head Band

Tongue

Headband | Front Holder | |

Size Slots | ||

|

Front Band Button B

Lugs

Figure 3.

! WARNING

The suspension maintains a fixed distance be- tween the head and the helmet. It is critical that the suspension is properly installed, and ad- justed as described, to provide maximum head protection and comfort.

6.2.1Remove the cape from the helmet per Section 9.4.

6.2.2Remove and discard the old suspension and suspension strap by extracting the plastic tabs from the

6.2.3Unfasten the vinyl sweatband from the two lower, outside buttons (A and B in Figure 3).

6.2.4The suspension fits head sizes 6.5 to 8. Head sizes are marked on the headband slots. Slide the headband tongue through the front holder until the desired head size is reached. It is important that the adjustment be made evenly on both sides. Press the selected slots firmly onto the lugs on the front band.

6.2.5Fasten the vinyl sweatband onto the buttons of the suspension.

6.2.6Install the suspension strap before installing the suspension. Insert the yellow end tabs into the clefts on the helmet shell. When correctly installed, the strap is between the suspension and helmet shell and above the ears.

6.2.7Install the suspension by inserting the four white plastic tabs into the clefts on the shell. The tabs must fully seat in their respective locators.

6.2.8Try the helmet on for fit and readjust if necessary.

6.2.9Check that the chin strap is in place, then reattach the cape onto the helmet following the instructions in Section 9.4.

7.0MAINTENANCE PROGRAM

7.1Basic Service

7.1.1A program for maintenance and care of the respi- rator must be established based on application, working conditions, and hazards involved, and include the follow- ing basic service.

•Inspection for defects (including a leak check)

•Cleaning and disinfecting

•Repair (service maintenance)

•Storage

Equipment must be properly maintained to retain its origi- nal effectiveness. [Reference OSHA Regulations 1910.134 (f)].

7.2Inspection

7.2.1Inspect respirators before and after each use. Inspection shall include a check for tightness of connec- tions and the condition of the lenses, suspension, cape and elastic parts, breathing tube, respirator hoses and connectors,

7.2.2The respirator hoses, breathing tube, air entry ports, and fittings must be checked for dust contamination, and cleaned before making connections.

7.2.3The helmet suspension is a very important com- ponent for maintaining maximum hard hat and respiratory protection. It must be inspected for fit and wear on a daily basis, and replaced immediately at the first sign of wear. (See Section 6.2)