ii.Low water detection – sets the low water detection on or off.

1.LOn, for low water on. (Factory Default)

2.LOF, for low water off.

iii.Low water reset – sets the low water reset for either automatic or manual

1.LAU, for low water automatic reset. (Factory Default)

2.LAn, for low water manual reset.

iv.Temperature units – sets the temperature units to either degrees Fahrenheit or Celsius.

1.DEF, for degrees Fahrenheit. (Factory Default)

2.DEC, for degrees Celsius.

v.Differential – sets the number of degrees below setpoint that the heater will resume heating after it has achieved setpoint.

1.d##, where ## is the differential in degrees (1 to 20). (Factory set at 02)

vi.Display – sets the display to either setpoint or actual temperature.

1.dSS, for display setpoint temperature. (Factory Default)

2.dSt, for display actual temperature.

e.To leave the configuration menu, wait 5 seconds without pushing any buttons or press the UP and DOWN buttons simultaneously.

5.To reset any

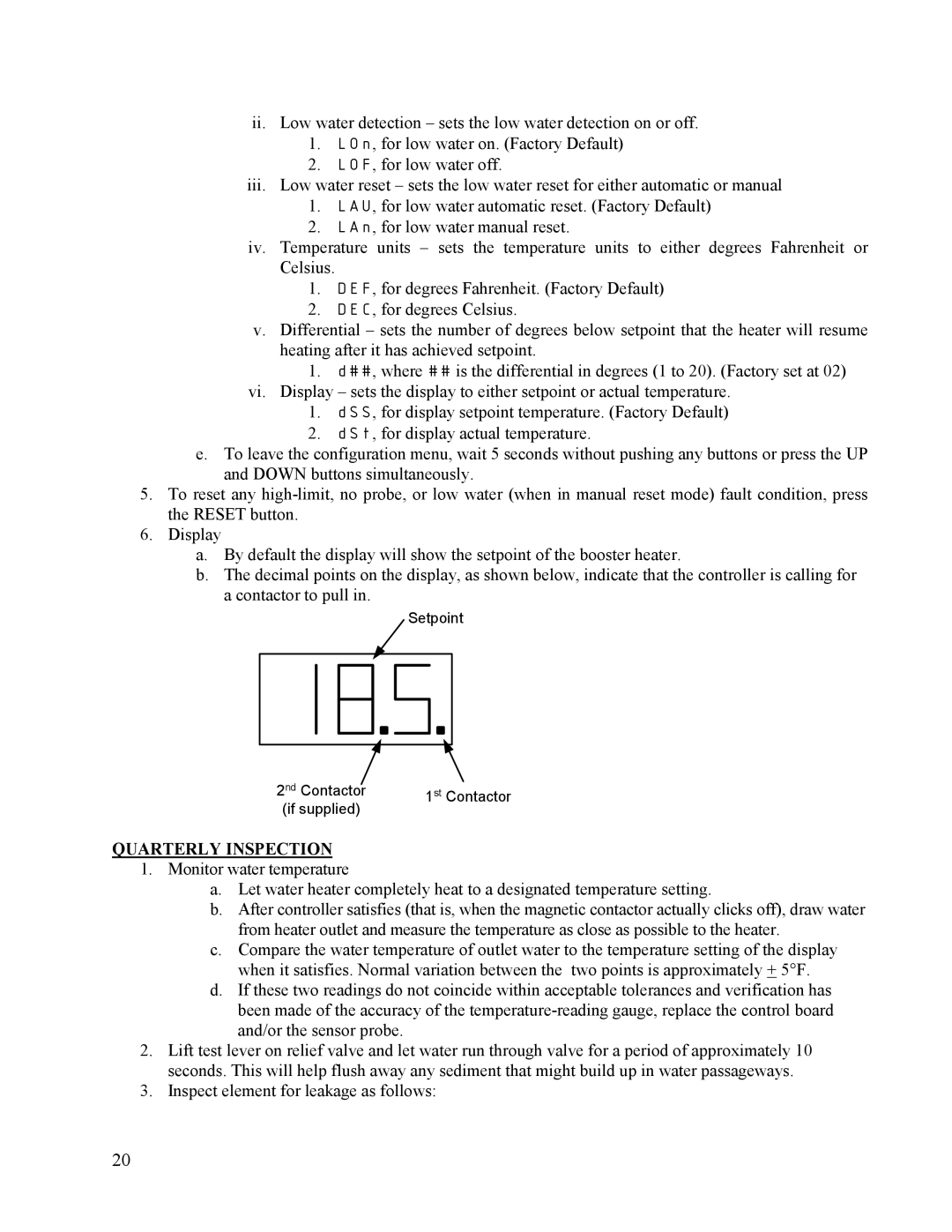

6.Display

a.By default the display will show the setpoint of the booster heater.

b.The decimal points on the display, as shown below, indicate that the controller is calling for a contactor to pull in.

2nd Contactor | 1st Contactor |

(if supplied) |

|

QUARTERLY INSPECTION

1.Monitor water temperature

a.Let water heater completely heat to a designated temperature setting.

b.After controller satisfies (that is, when the magnetic contactor actually clicks off), draw water from heater outlet and measure the temperature as close as possible to the heater.

c.Compare the water temperature of outlet water to the temperature setting of the display when it satisfies. Normal variation between the two points is approximately + 5°F.

d.If these two readings do not coincide within acceptable tolerances and verification has been made of the accuracy of the

2.Lift test lever on relief valve and let water run through valve for a period of approximately 10 seconds. This will help flush away any sediment that might build up in water passageways.

3.Inspect element for leakage as follows:

20