3.Put approximately one inch of water in the bottom of the boat.

4.Put transducer in the water. The bottom of the transducer should be in a flat area and should be in good contact with the bottom of the boat. 5. Operate the unit with the boat operating at high speed. The transducer may have to be moved in order to find an area where satisfactory operation is observed.

6.When an area is found that produces satisfactory operation, mark the location of the transducer.

7.Remove the water and transducer and clean the marked area and the bottom of the transducer thoroughly.

8.Using the Humminbird Epoxy Kit mix an ample amount of epoxy without causing it to bubble and pour it in the area the transducer is to be mounted. The puddle should be larger than the bottom of the transducer.

9.Coat the bottom of the transducer with epoxy, then put in the center of the puddle and push down on transducer while moving it around in a circular motion. This forces out any air bubbles that may be trapped between the bottom of the transducer and the hull of the boat.

10.Let epoxy cure then the transducer is ready to operate. No water is now required in the bottom of the boat and gas and oil that is spilled inside of the boat will not degrade performance as it will if the transducer is placed only in water. Caution: Do not use silicone seal or any soft adhesive to bond the transducer to the hull. This will reduce the sensitivity of the unit.

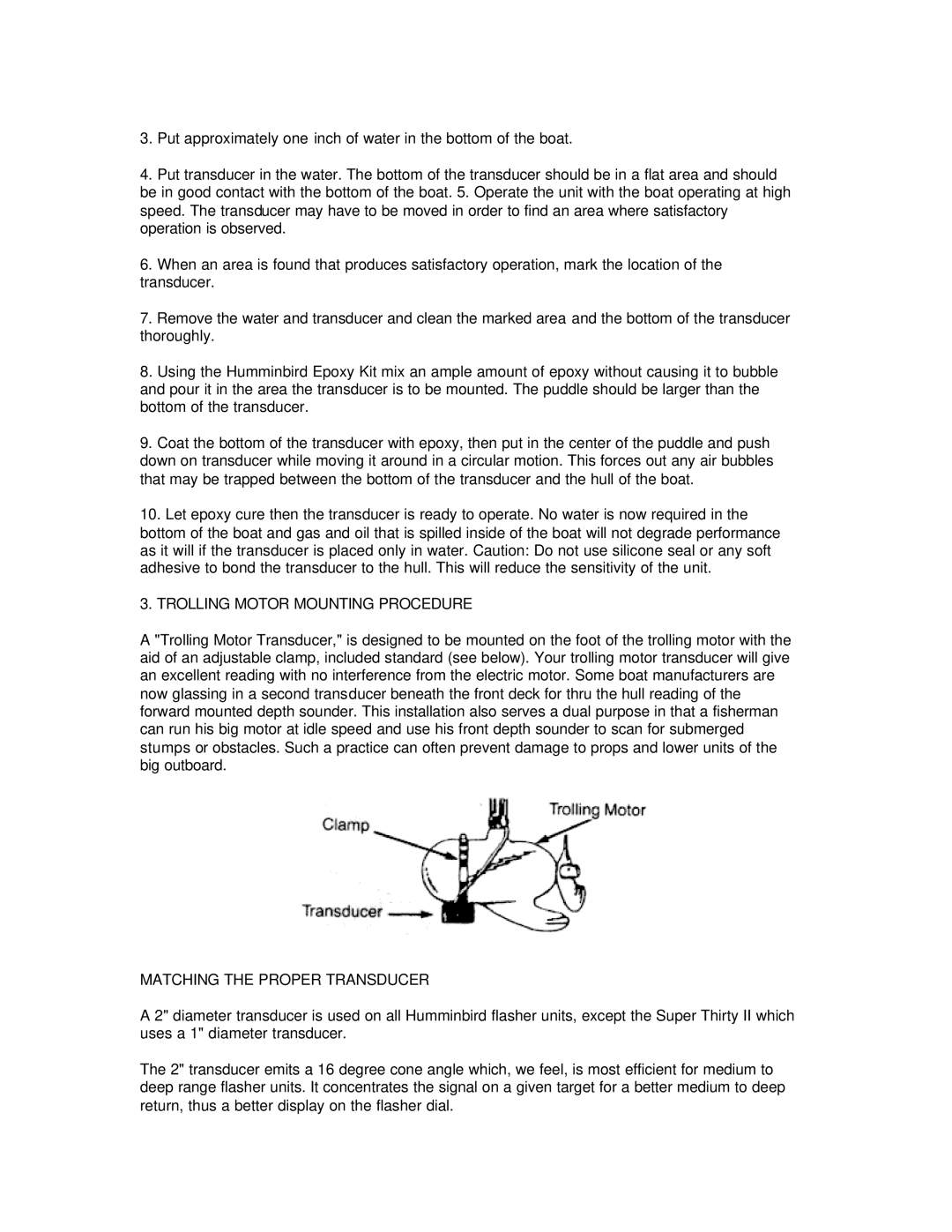

3. TROLLING MOTOR MOUNTING PROCEDURE

A "Trolling Motor Transducer," is designed to be mounted on the foot of the trolling motor with the aid of an adjustable clamp, included standard (see below). Your trolling motor transducer will give an excellent reading with no interference from the electric motor. Some boat manufacturers are now glassing in a second transducer beneath the front deck for thru the hull reading of the forward mounted depth sounder. This installation also serves a dual purpose in that a fisherman can run his big motor at idle speed and use his front depth sounder to scan for submerged stumps or obstacles. Such a practice can often prevent damage to props and lower units of the big outboard.

MATCHING THE PROPER TRANSDUCER

A 2" diameter transducer is used on all Humminbird flasher units, except the Super Thirty II which uses a 1" diameter transducer.

The 2" transducer emits a 16 degree cone angle which, we feel, is most efficient for medium to deep range flasher units. It concentrates the signal on a given target for a better medium to deep return, thus a better display on the flasher dial.