Oilless Compressors

Operation (Cont.)

Handle - Designed to move the compressor.

Tool Storage - 1/4 inch quick connect couplers fit in holes to support air chuck and other inflation fittings.

Never use the

! WARNING handle on wheeled units to lift the unit completely off the ground.

Drain Petcock - This valve is located on the bottom of the tank. Use this valve to drain moisture from the tank daily to reduce the risk of corrosion.

Reduce tank pressure below 10 PSI, then drain moisture from tank daily to avoid tank corrosion. Drain moisture from tank(s) by opening the drain petcock located underneath the tank.

LUBRICATION

This is an oilless product and DOES NOT require lubrication to operate. IMPORTANT: Do not operate compres- sor before reading instructions or damage may result.

1.Turn switch to OFF position and plug in power cord.

MOISTURE IN COMPRESSED AIR

Moisture in compressed air will form into droplets as it comes from an air compressor pump. When humidity is high or when a compressor is in continuous use for an extended period of time, this moisture will collect in the tank. When using a paint spray or sandblast gun, this water will be carried from the tank through the hose, and out of the gun as droplets mixed with the spray material.

IMPORTANT: This condensation will cause water spots in a paint job, especially when spraying other than water based paints. If sandblasting, it will cause the sand to cake and clog the gun, rendering it ineffective. A filter in the air line (MP3105), located as near to the gun as possible, will help eliminate this moisture.

2.Attach hose to compressor outlet.

3.Attach chuck or other tool to open end of hose.

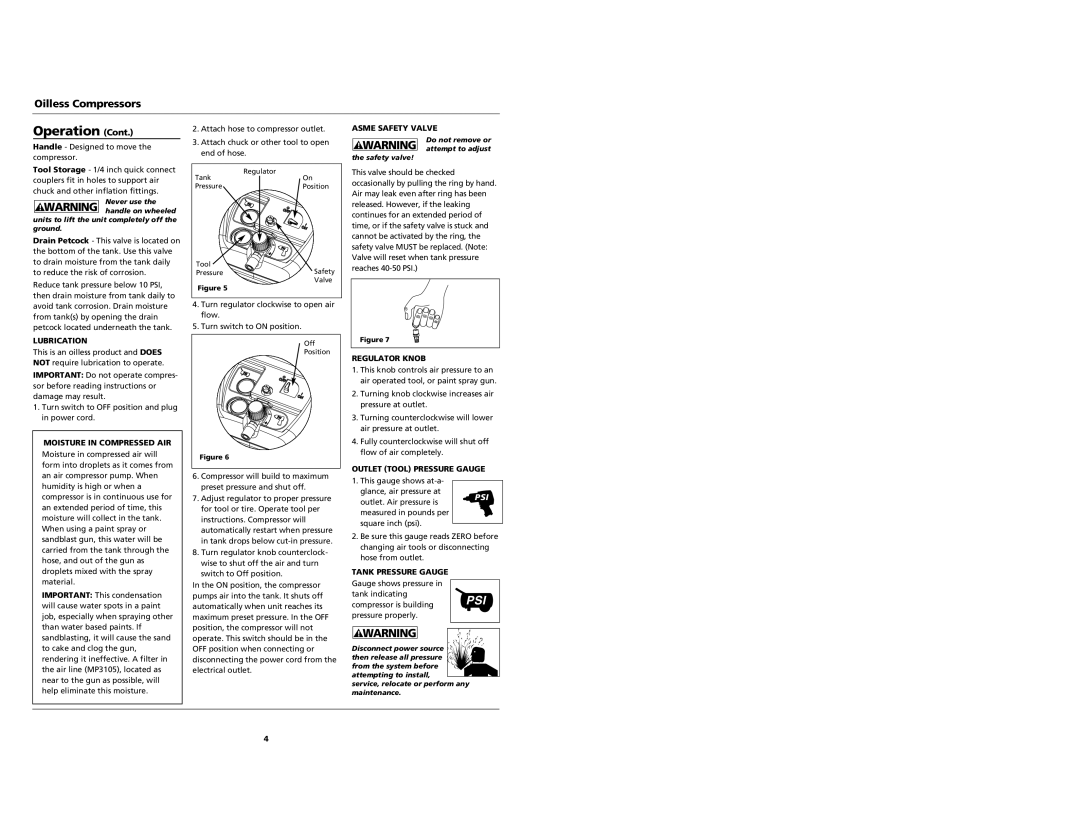

Tank | Regulator |

On | |

Pressure | Position |

Tool | Safety |

Pressure | |

| Valve |

Figure 5 |

|

4.Turn regulator clockwise to open air flow.

5.Turn switch to ON position.

Off |

Position |

Figure 6 |

6.Compressor will build to maximum preset pressure and shut off.

7.Adjust regulator to proper pressure for tool or tire. Operate tool per instructions. Compressor will automatically restart when pressure in tank drops below

8.Turn regulator knob counterclock- wise to shut off the air and turn switch to Off position.

In the ON position, the compressor pumps air into the tank. It shuts off automatically when unit reaches its maximum preset pressure. In the OFF position, the compressor will not operate. This switch should be in the OFF position when connecting or disconnecting the power cord from the electrical outlet.

ASME SAFETY VALVE

! WARNING | Do not remove or |

attempt to adjust |

the safety valve!

This valve should be checked occasionally by pulling the ring by hand. Air may leak even after ring has been released. However, if the leaking continues for an extended period of time, or if the safety valve is stuck and cannot be activated by the ring, the safety valve MUST be replaced. (Note: Valve will reset when tank pressure reaches

Figure 7

REGULATOR KNOB

1.This knob controls air pressure to an air operated tool, or paint spray gun.

2.Turning knob clockwise increases air pressure at outlet.

3.Turning counterclockwise will lower air pressure at outlet.

4.Fully counterclockwise will shut off flow of air completely.

OUTLET (TOOL) PRESSURE GAUGE

1. This gauge shows |

| |

| ||

glance, air pressure at | PSI | |

outlet. Air pressure is | ||

| ||

measured in pounds per |

| |

square inch (psi). |

| |

|

2.Be sure this gauge reads ZERO before changing air tools or disconnecting hose from outlet.

TANK PRESSURE GAUGE |

|

Gauge shows pressure in |

|

tank indicating | PSI |

compressor is building | |

pressure properly. |

|

! WARNING

Disconnect power source ![]()

![]()

![]()

![]() then release all pressure

then release all pressure ![]()

![]()

![]()

![]()

![]()

![]() from the system before

from the system before ![]()

![]()

![]()

![]()

![]() attempting to install,

attempting to install,

service, relocate or perform any maintenance.

4