137, 142 specifications

The Husqvarna 137 and 142 are popular chainsaw models known for their reliability and performance, catering to both residential and light professional use. Bringing together a blend of innovative technologies and user-friendly features, these models have been designed to ensure that tasks such as tree pruning, firewood cutting, and light felling can be conducted efficiently and safely.One of the standout features of both the Husqvarna 137 and 142 is their lightweight construction. Weighing in at approximately 4.5 kg, these chainsaws are easy to handle, particularly for users who may need to work for extended periods. This lightweight design significantly reduces fatigue, enabling operators to work longer without the weariness often associated with heavy machinery.

Powering these chainsaws is a robust 2.0 kW engine, which delivers an optimal balance of performance and efficiency. The engine has been engineered to provide a fast and consistent chain speed, allowing for clean and precise cuts. An efficient air filtration system contributes to the longevity of the engine, ensuring less frequent cleaning and maintenance. This feature is particularly advantageous for users who rely on their equipment for frequent tasks.

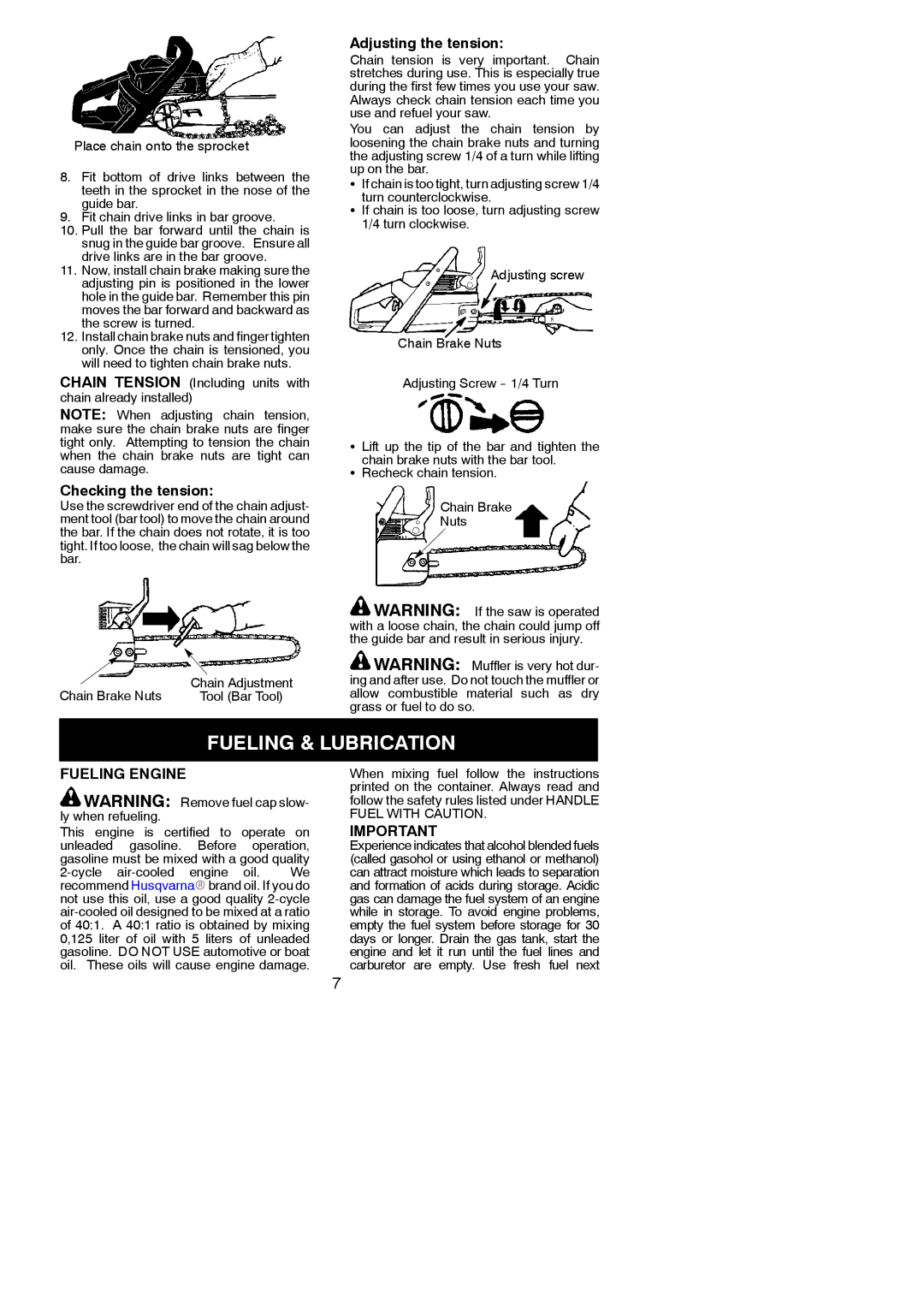

Both models come equipped with an automatic oil pump that ensures proper lubrication of the chain and bar during operation. This feature not only extends the life of the chainsaw but also enhances cutting efficiency. Additionally, the chain tensioning system is designed for easy adjustments, providing users with the ability to maintain the proper tension with minimal effort.

Safety is also a key consideration in the design of the Husqvarna 137 and 142. These models feature a chain brake that effectively stops the chain's movement in the event of kickback, protecting the operator from potential injury. Furthermore, the anti-vibration technology integrated into the handles helps to reduce vibrations felt by the user, contributing to a more comfortable and safer operating experience.

The ergonomic design is complemented by an intuitive layout, with controls that are easy to access and operate. The combination of performance, safety features, and user-centric design makes the Husqvarna 137 and 142 excellent choices for anyone needing a dependable chainsaw for various tasks. These models offer a powerful, efficient, and comfortable experience, making them an ideal investment for both hobbyists and occasional users alike.