MAINTENANCE

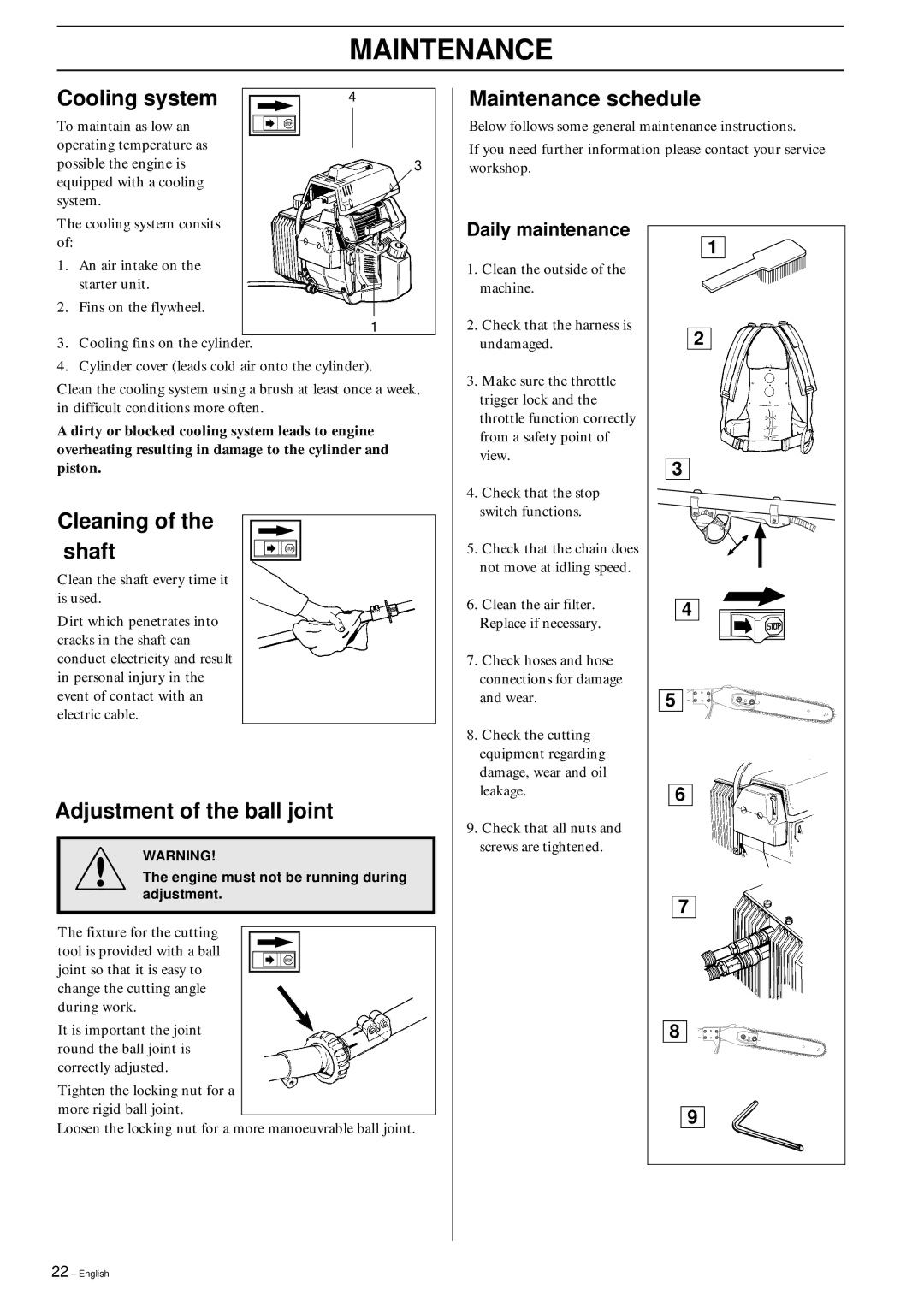

Cooling system

To maintain as low an operating temperature as possible the engine is equipped with a cooling system.

4

3

Maintenance schedule

Below follows some general maintenance instructions.

If you need further information please contact your service workshop.

The cooling system consits of:

1.An air intake on the starter unit.

2.Fins on the flywheel.

1

Daily maintenance

1. | Clean the outside of the |

| machine. |

2. | Check that the harness is |

1 |

3.Cooling fins on the cylinder.

4.Cylinder cover (leads cold air onto the cylinder).

Clean the cooling system using a brush at least once a week, in difficult conditions more often.

A dirty or blocked cooling system leads to engine overheating resulting in damage to the cylinder and piston.

Cleaning of the shaft

Clean the shaft every time it is used.

Dirt which penetrates into cracks in the shaft can conduct electricity and result in personal injury in the event of contact with an electric cable.

Adjustment of the ball joint

!WARNING!

The engine must not be running during adjustment.

The fixture for the cutting tool is provided with a ball joint so that it is easy to change the cutting angle during work.

It is important the joint round the ball joint is correctly adjusted.

Tighten the locking nut for a more rigid ball joint.

Loosen the locking nut for a more manoeuvrable ball joint.

| undamaged. |

3. | Make sure the throttle |

| trigger lock and the |

| throttle function correctly |

| from a safety point of |

| view. |

4. | Check that the stop |

| switch functions. |

5. | Check that the chain does |

| not move at idling speed. |

6. | Clean the air filter. |

| Replace if necessary. |

7. | Check hoses and hose |

| connections for damage |

| and wear. |

8. | Check the cutting |

| equipment regarding |

| damage, wear and oil |

| leakage. |

9. | Check that all nuts and |

| screws are tightened. |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

22 – English