SAFETY INSTRUCTIONS

B. Procedure if the lubrication does not function:

1. Check that the oil channel in the bar is not obstructed. Clean if necessary.

2.Check that the groove in the edge of the bar is

clean. Clean if necessary.

3.Check that the bar tip sprocket turns freely.

If the chain lubrication system is still not working after carrying out the above measures you should contact your service agent.

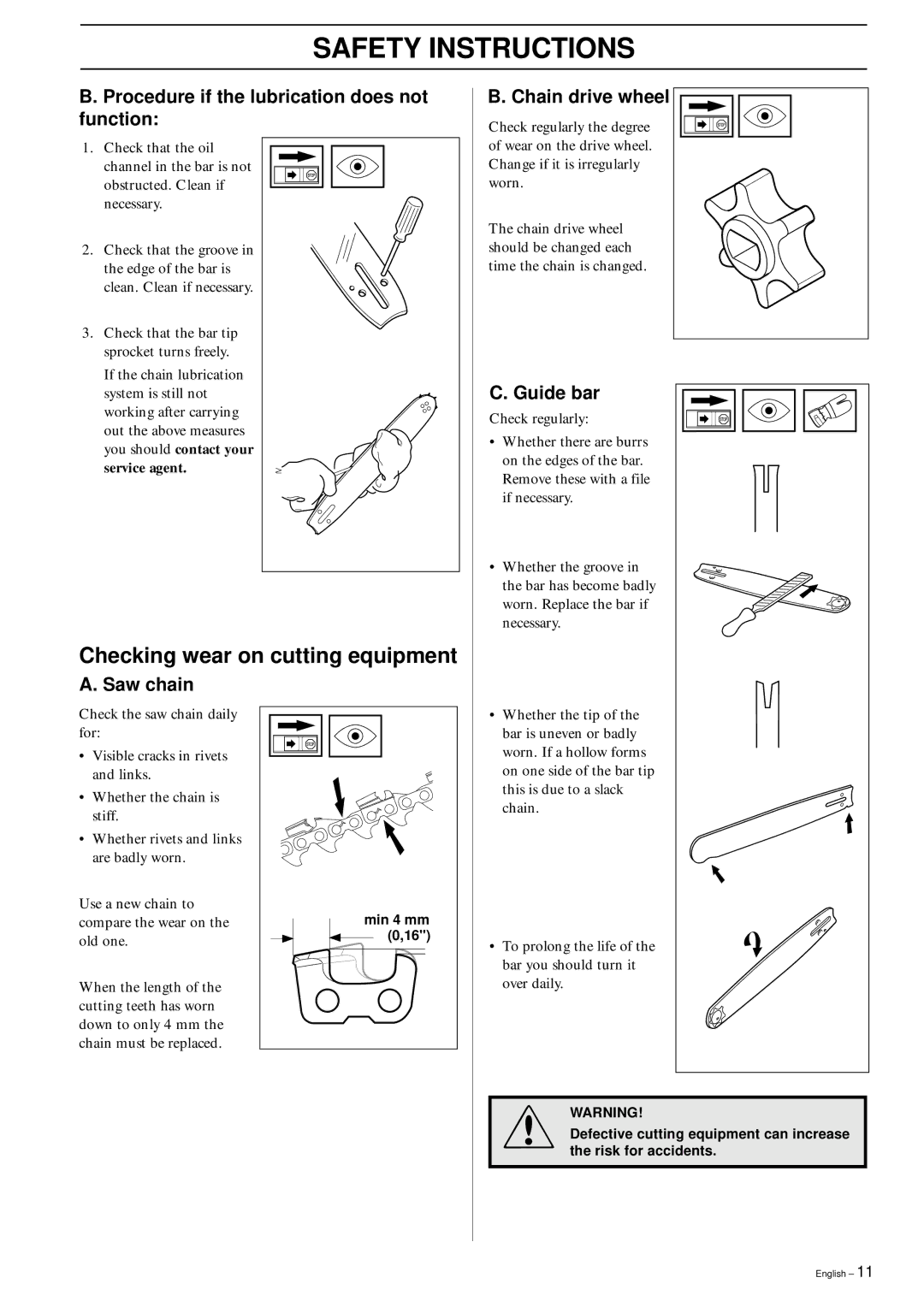

Checking wear on cutting equipment

A. Saw chain

B. Chain drive wheel

Check regularly the degree of wear on the drive wheel. Change if it is irregularly worn.

The chain drive wheel should be changed each time the chain is changed.

C. Guide bar

Check regularly:

• | Whether there are burrs |

| on the edges of the bar. |

| Remove these with a file |

| if necessary. |

• | Whether the groove in |

| the bar has become badly |

| worn. Replace the bar if |

| necessary. |

Check the saw chain daily for:

•Visible cracks in rivets and links.

•Whether the chain is stiff.

•Whether rivets and links are badly worn.

Use a new chain to compare the wear on the old one.

When the length of the cutting teeth has worn down to only 4 mm the chain must be replaced.

min 4 mm |

(0,16") |

• Whether the tip of the |

bar is uneven or badly |

worn. If a hollow forms |

on one side of the bar tip |

this is due to a slack |

chain.

•To prolong the life of the bar you should turn it over daily.

!WARNING!

Defective cutting equipment can increase the risk for accidents.

English – 11