288XP/XP lite specifications

The Husqvarna 288XP and XP Lite chainsaws represent a pinnacle in forestry and tree care technology, designed for professionals who demand high performance and reliability in demanding environments. These models are renowned for their robust construction and impressive power-to-weight ratios, making them suitable for a variety of cutting tasks.One of the standout features of the Husqvarna 288XP is its powerful engine. Equipped with a 75.6 cc two-stroke engine, it delivers a remarkable power output while maintaining efficiency. This ensures that the chainsaw can handle even the most challenging applications, from felling large trees to limbing and bucking with ease. The XP Lite version offers a slightly lighter design, making it more maneuverable while still delivering ample power for professional use.

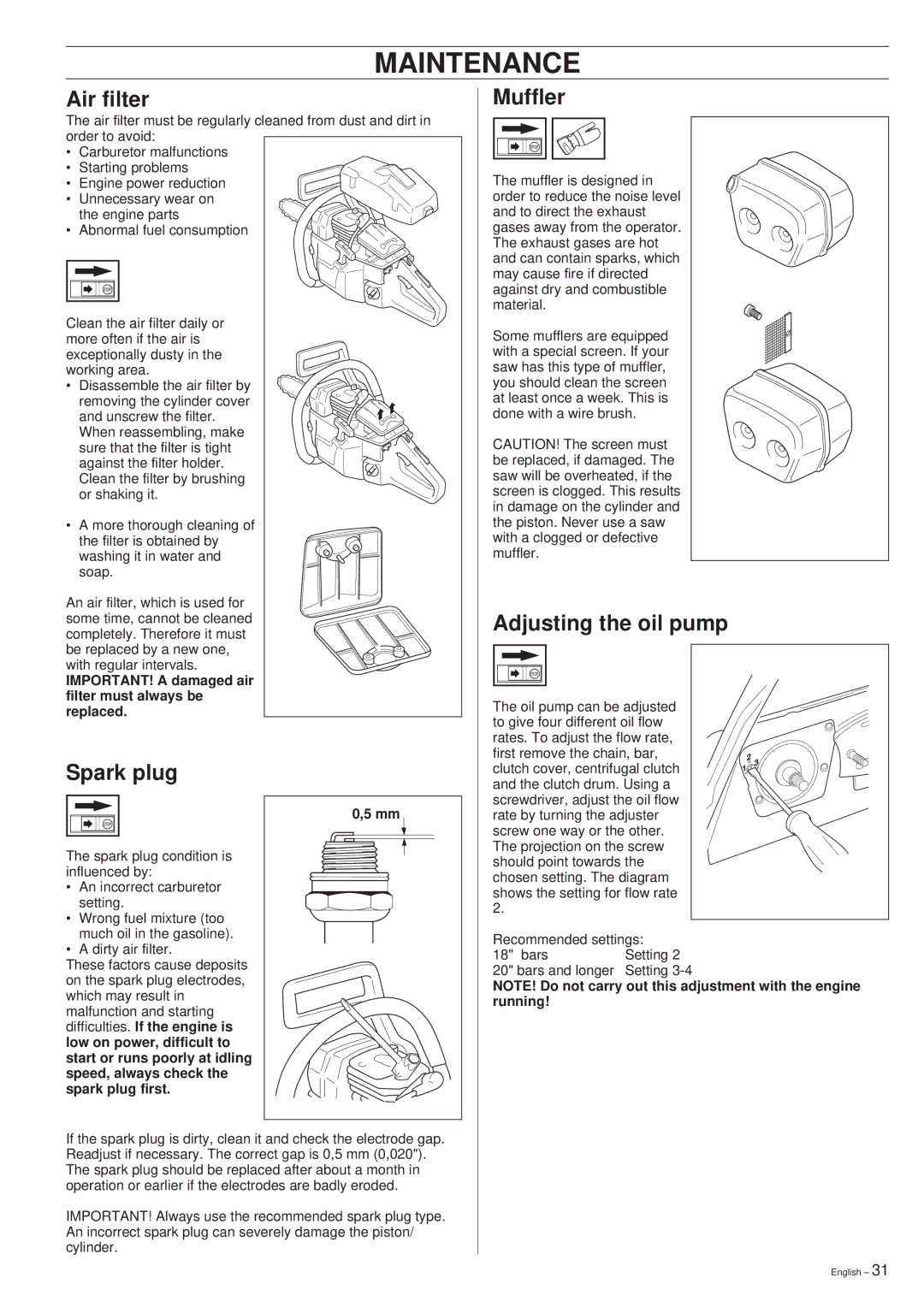

The chainsaw also incorporates a high-performance air injection system. This unique technology helps to keep the air filter cleaner for longer periods by using centrifugal force to remove larger dust and debris particles before they reach the filter. As a result, users benefit from extended service intervals and less downtime for maintenance, which is crucial in professional settings.

Noise reduction is another important feature of the Husqvarna 288XP series. The saw is equipped with effective vibration damping, reducing fatigue during long operational hours. Additionally, it boasts advanced muffler technologies that help minimize noise levels, allowing operators to work in a variety of environments without disturbing the peace.

Ergonomics play a significant role in the design of these chainsaws. The adjustable chain oil flow ensures optimal lubrication, which improves cutting efficiency and prolongs the life of the chain and bar. The chainsaws also feature an ergonomic handle design, providing comfort and control during use, which is essential for precision cutting.

Safety is paramount in chainsaw design, and the Husqvarna 288XP includes several safety features, such as a chain brake, which activates in the event of kickback, protecting the operator from accidents. The tool-free chain tensioning system allows for quick adjustments on the job, further enhancing user safety and efficiency.

In summary, the Husqvarna 288XP and XP Lite chainsaws are engineered for the professional user who values performance, durability, and safety. With their powerful engines, innovative technologies, ergonomic designs, and commitment to user comfort and safety, these chainsaws are the ideal choice for those working in the most demanding forestry and tree care situations. Whether tackling large-scale projects or precision tasks, the Husqvarna 288XP series is built to meet and exceed expectations.