MAINTENANCE

Air filter

The air filter must be regularly cleaned from dust and dirt in order to avoid:

•Carburetor malfunctions

•Starting problems

• Engine power reduction

• Unnecessary wear on the engine parts

• Abnormal fuel consumption

Clean the air filter daily or more often if the air is exceptionally dusty in the working area.

• Disassemble the air filter by removing the cylinder cover and unscrew the filter.

When reassembling, make sure that the filter is tight against the filter holder. Clean the filter by brushing or shaking it.

• A more thorough cleaning of the filter is obtained by

Muffler

The muffler is designed in order to reduce the noise level and to direct the exhaust

gases away from the operator. The exhaust gases are hot

and can contain sparks, which may cause fire if directed against dry and combustible material. Some mufflers are equipped with a special screen.

If your saw has this type of muffler, you should clean the screen at least once a week. This is done with a wire brush.

CAUTION! The screen must be replaced, if damaged. The saw will be overheated, if the screen is clogged. This results in damage on the cylinder and the piston. Never use a saw with a clogged or defective muffler.

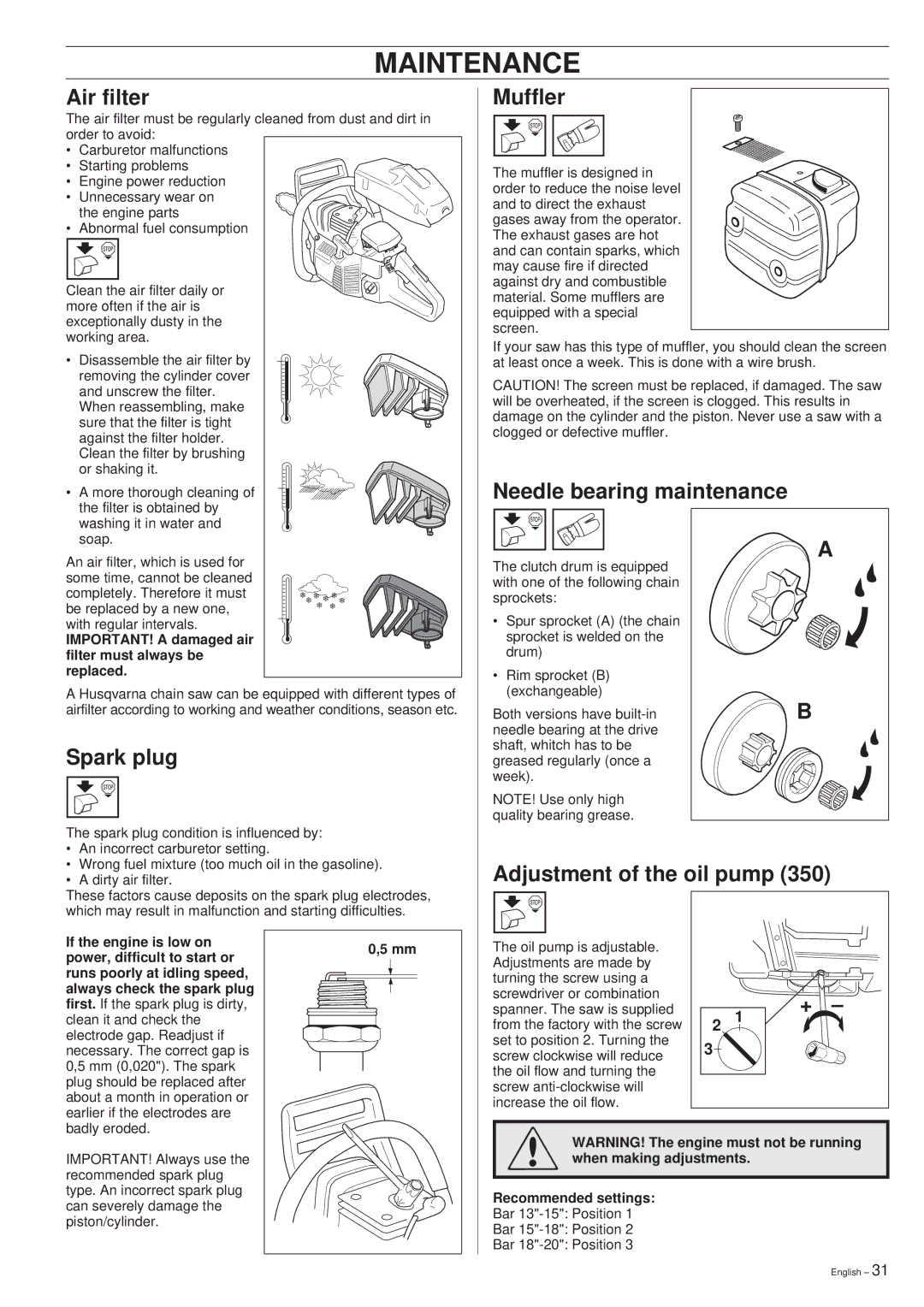

Needle bearing maintenance

washing it in water and soap.

An air filter, which is used for some time, cannot be cleaned completely. Therefore it must be replaced by a new one, with regular intervals.

IMPORTANT! A damaged air filter must always be replaced.

A Husqvarna chain saw can be equipped with different types of airfilter according to working and weather conditions, season etc.

Spark plug

The spark plug condition is influenced by:

The clutch drum is equipped with one of the following chain sprockets:

•Spur sprocket (A) (the chain sprocket is welded on the drum)

•Rim sprocket (B) (exchangeable)

Both versions have

NOTE! Use only high quality bearing grease.

A |

B |

•An incorrect carburetor setting.

•Wrong fuel mixture (too much oil in the gasoline).

•A dirty air filter.

Adjustment of the oil pump (350)

These factors cause deposits on the spark plug electrodes, which may result in malfunction and starting difficulties.

If the engine is low on | 0,5 mm | |

power, difficult to start or | ||

| ||

runs poorly at idling speed, |

| |

always check the spark plug |

| |

first. If the spark plug is dirty, |

| |

clean it and check the |

| |

electrode gap. Readjust if |

| |

necessary. The correct gap is |

| |

0,5 mm (0,020"). The spark |

| |

plug should be replaced after |

| |

about a month in operation or |

| |

earlier if the electrodes are |

|

The oil pump is adjustable. Adjustments are made by turning the screw using a screwdriver or combination spanner. The saw is supplied from the factory with the screw set to position 2. Turning the screw clockwise will reduce the oil flow and turning the screw

| + | – |

2 | 1 |

|

3 |

|

|

badly eroded. |

IMPORTANT! Always use the recommended spark plug type. An incorrect spark plug can severely damage the piston/cylinder.

!WARNING! The engine must not be running when making adjustments.

Recommended settings:

Bar

Bar

Bar

English – 31