MAINTENANCE

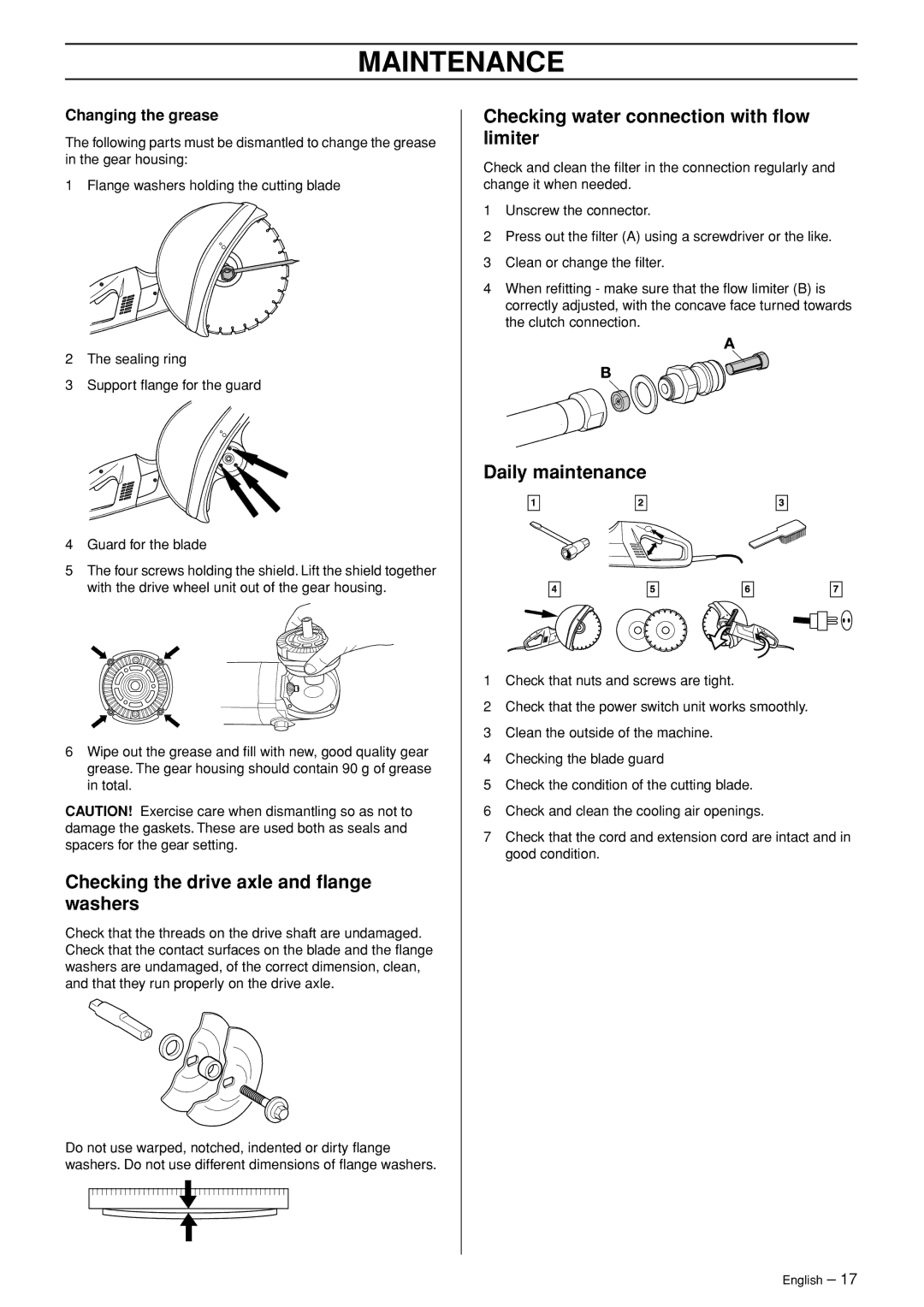

Changing the grease

The following parts must be dismantled to change the grease in the gear housing:

1 Flange washers holding the cutting blade

2The sealing ring

3Support flange for the guard

4Guard for the blade

5The four screws holding the shield. Lift the shield together with the drive wheel unit out of the gear housing.

6Wipe out the grease and fill with new, good quality gear grease. The gear housing should contain 90 g of grease in total.

CAUTION! Exercise care when dismantling so as not to damage the gaskets. These are used both as seals and spacers for the gear setting.

Checking the drive axle and flange washers

Check that the threads on the drive shaft are undamaged. Check that the contact surfaces on the blade and the flange washers are undamaged, of the correct dimension, clean, and that they run properly on the drive axle.

Do not use warped, notched, indented or dirty flange washers. Do not use different dimensions of flange washers.

Checking water connection with flow limiter

Check and clean the filter in the connection regularly and change it when needed.

1Unscrew the connector.

2Press out the filter (A) using a screwdriver or the like.

3Clean or change the filter.

4When refitting - make sure that the flow limiter (B) is correctly adjusted, with the concave face turned towards the clutch connection.

Daily maintenance

1Check that nuts and screws are tight.

2Check that the power switch unit works smoothly.

3Clean the outside of the machine.

4Checking the blade guard

5Check the condition of the cutting blade.

6Check and clean the cooling air openings.

7Check that the cord and extension cord are intact and in good condition.

English – 17