SAFETY INSTRUCTIONS

Machine′s safety equipment

This section describes the machine′s safety equipment, its purpose, and how checks and maintenance should be carried out to ensure that it operates correctly. See the ”What is what?” section to locate where this equipment is positioned on your machine.

WARNING! Never use a machine that has

!faulty safety equipment! Carry out the inspection, maintenance and service routines listed in this section.

All servicing and repair work on the machine requires special training. This is especially true of the machine′s safety equipment. If your machine fails any of the checks described below you must contact your service agent. When you buy any of our products we guarantee the availability of professional repairs and service. If the retailer who sells your machine is not a servicing dealer, ask him for the address of your nearest service agent.

Switch

The power switch should be used to start and stop the machine.

Checking the power switch

•Start the machine, release the power switch and check that the engine and the cutting blade stop.

•A defective power switch should be replaced by an authorized service workshop.

Power switch lock

The power switch lock is designed to prevent accidental operation of the switch. When the lock (A) is pressed in the power switch (B) is released.

The power switch lock remains depressed as long as the power switch is depressed. When the grip on the handle is released both the power switch and power switch lock are reset. This movement is controlled by two independent return springs. This position results in the machine stopping and the power switch being locked.

Checking the power switch lock

•Make sure the power switch is locked when the power switch lock is in its original position.

•Press in the power switch lock and make sure it returns to its original position when you release it.

•Check that the power switch and power switch lock move freely and that the return springs work properly.

•Start the machine, release the power switch and check that the engine and the cutting blade stop.

Gradual start and overload protection

The machine is equipped with electronically controlled gradual start and overload protection.

The engine starts to pulsate if the machine is loaded above a specific level. If the load is reduced the engine reverts to its normal state and cutting can resume.

The electronics will cut the current after a set time if the machine continues to be run with a pulsating engine. The higher load the faster the shutoff.

The electronics cut the current immediately if the blade jams.

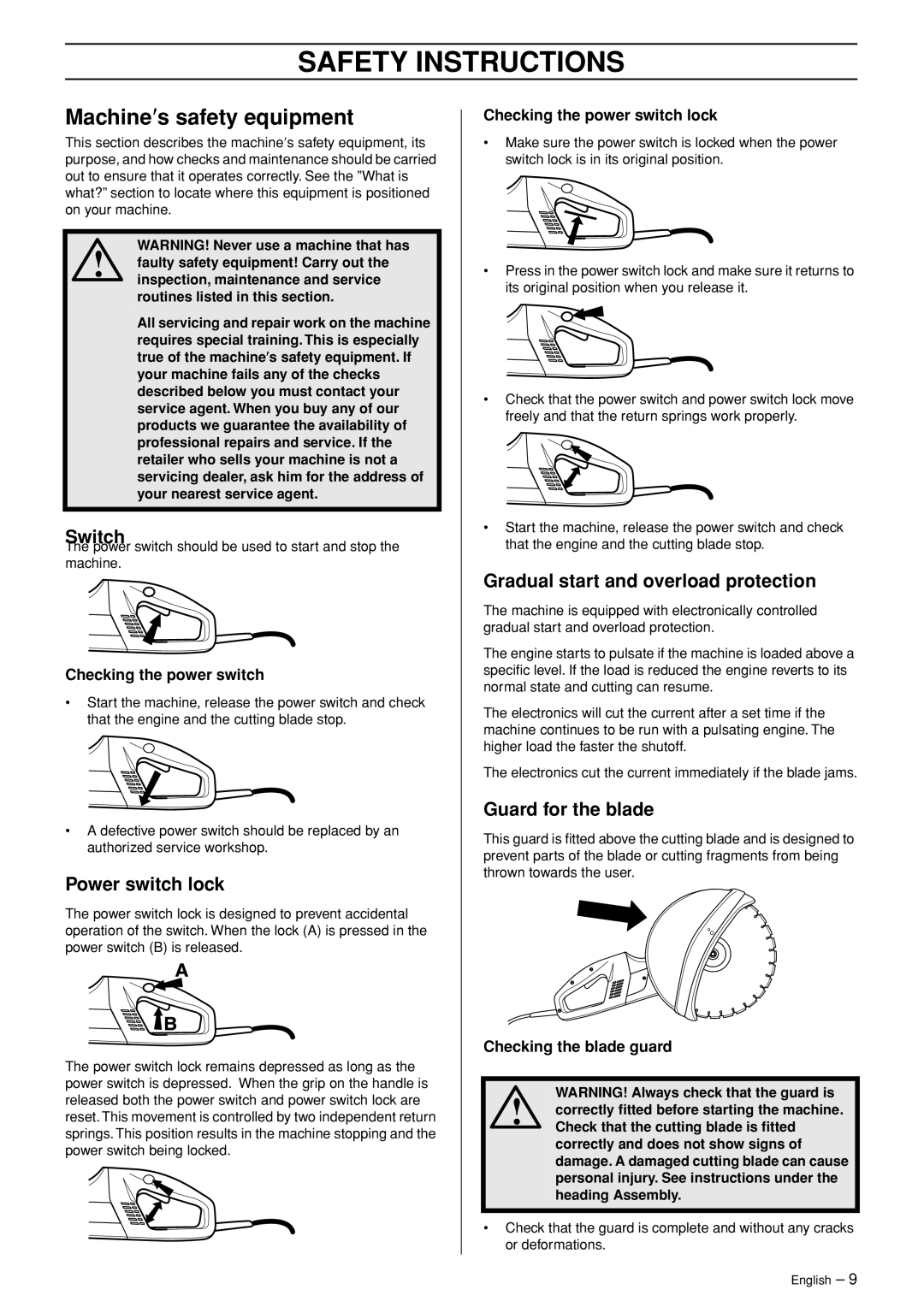

Guard for the blade

This guard is fitted above the cutting blade and is designed to prevent parts of the blade or cutting fragments from being thrown towards the user.

Checking the blade guard

WARNING! Always check that the guard is

!correctly fitted before starting the machine. Check that the cutting blade is fitted correctly and does not show signs of damage. A damaged cutting blade can cause personal injury. See instructions under the heading Assembly.

•Check that the guard is complete and without any cracks or deformations.

English – 9