SAFETY INSTRUCTIONS

Safety

Plan the work so that you do not get crushed by the bar when the pieces fall apart. Planning is also extremely important for your own safety! As it is usually a question of large and heavy pieces that are cut when using the diamond chain saw the forces are so great that jamming can result in irreparable damage to both the bar and chain.

You must plan before you start to cut how to support the workpiece according to how the pieces separate once cutting has been completed. In those cases where it is difficult to calculate how the pieces will fall apart, or when it is impossible to support the workpiece as you would like, wedging in the cut slot is a good and safe method.

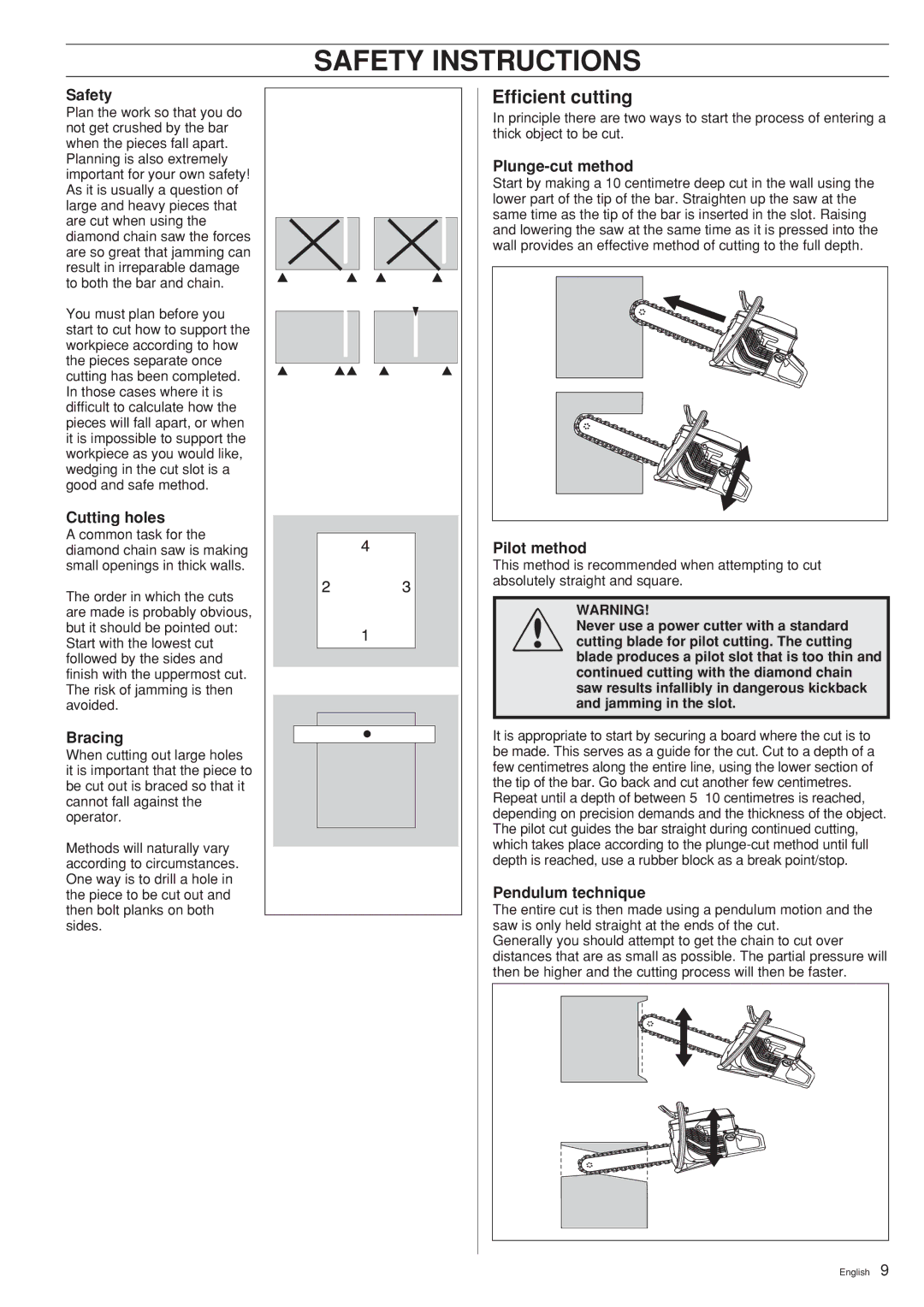

Cutting holes

A common task for the diamond chain saw is making small openings in thick walls.

The order in which the cuts are made is probably obvious, but it should be pointed out: Start with the lowest cut followed by the sides and finish with the uppermost cut. The risk of jamming is then avoided.

Bracing

When cutting out large holes it is important that the piece to be cut out is braced so that it cannot fall against the operator.

Methods will naturally vary according to circumstances. One way is to drill a hole in the piece to be cut out and then bolt planks on both sides.

Efficient cutting

In principle there are two ways to start the process of entering a thick object to be cut.

Plunge-cut method

Start by making a 10 centimetre deep cut in the wall using the lower part of the tip of the bar. Straighten up the saw at the same time as the tip of the bar is inserted in the slot. Raising and lowering the saw at the same time as it is pressed into the wall provides an effective method of cutting to the full depth.

Pilot method

This method is recommended when attempting to cut absolutely straight and square.

!WARNING!

Never use a power cutter with a standard cutting blade for pilot cutting. The cutting blade produces a pilot slot that is too thin and continued cutting with the diamond chain saw results infallibly in dangerous kickback and jamming in the slot.

It is appropriate to start by securing a board where the cut is to be made. This serves as a guide for the cut. Cut to a depth of a few centimetres along the entire line, using the lower section of the tip of the bar. Go back and cut another few centimetres.

Repeat until a depth of between

Pendulum technique

The entire cut is then made using a pendulum motion and the saw is only held straight at the ends of the cut.

Generally you should attempt to get the chain to cut over distances that are as small as possible. The partial pressure will then be higher and the cutting process will then be faster.

English – 9