MAINTENANCE

•Use a 19 mm fixed spanner and a 13 mm combination spanner to replace the rollers.

•Lubricate using bearing grease inside the rollers before the new rollers are fitted.

Drive wheel

NOTICE! Replace the drive wheel when fitting a new blade. A worn drive wheel can result in the blade slipping and becoming damaged.

Inadequate water flow drastically shortens the life of the drive wheel.

Replacing the drive wheel

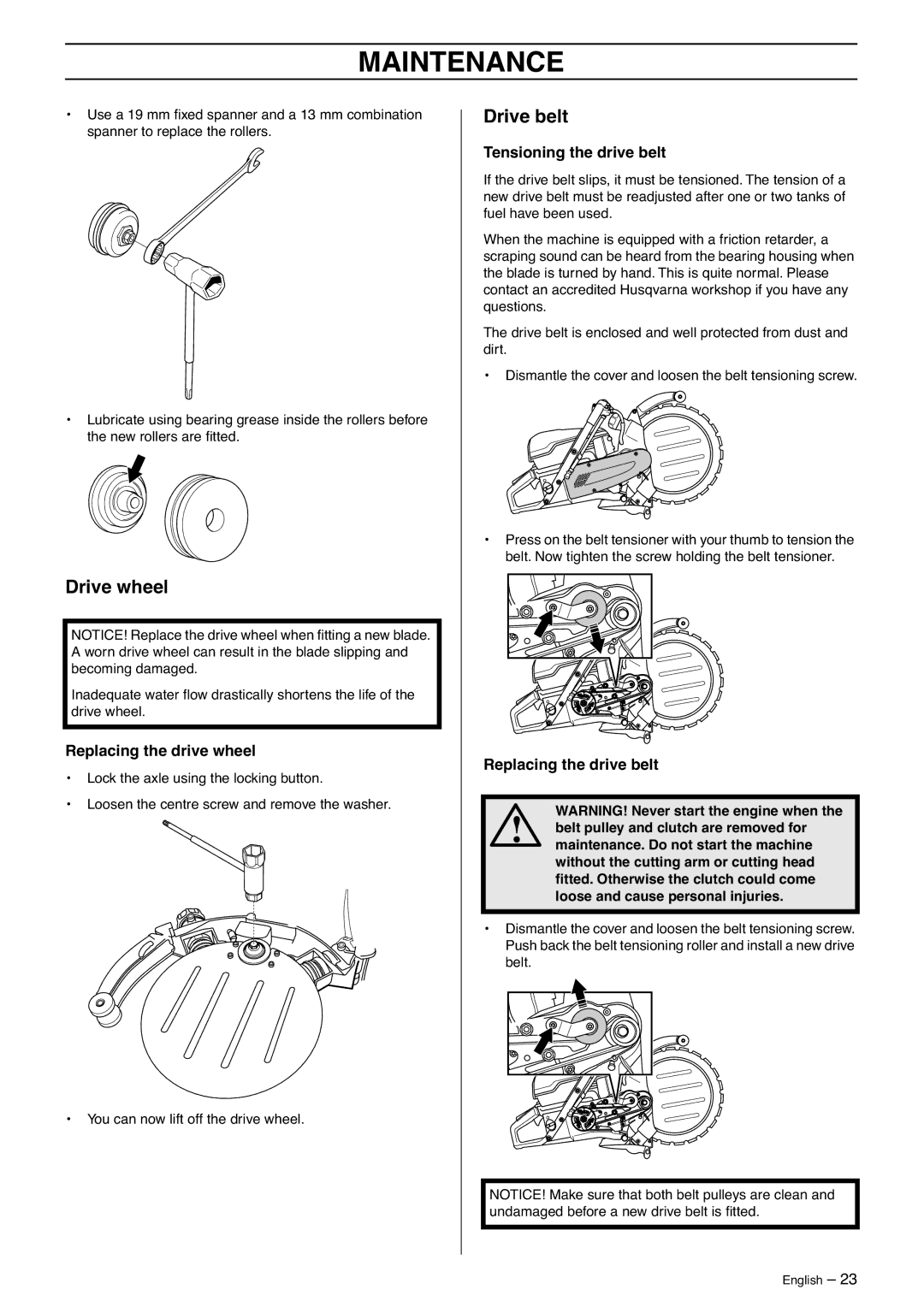

•Lock the axle using the locking button.

•Loosen the centre screw and remove the washer.

•You can now lift off the drive wheel.

Drive belt

Tensioning the drive belt

If the drive belt slips, it must be tensioned. The tension of a new drive belt must be readjusted after one or two tanks of fuel have been used.

When the machine is equipped with a friction retarder, a scraping sound can be heard from the bearing housing when the blade is turned by hand. This is quite normal. Please contact an accredited Husqvarna workshop if you have any questions.

The drive belt is enclosed and well protected from dust and dirt.

•Dismantle the cover and loosen the belt tensioning screw.

•Press on the belt tensioner with your thumb to tension the belt. Now tighten the screw holding the belt tensioner.

Replacing the drive belt

WARNING! Never start the engine when the

!belt pulley and clutch are removed for maintenance. Do not start the machine without the cutting arm or cutting head fitted. Otherwise the clutch could come loose and cause personal injuries.

•Dismantle the cover and loosen the belt tensioning screw. Push back the belt tensioning roller and install a new drive belt.

NOTICE! Make sure that both belt pulleys are clean and undamaged before a new drive belt is fitted.

English – 23