Engine oil

dipstick and fill

Fig.

General engine maintenance

Detailed instructions and recommendations for

Belts

Inspect belts frequently for wear and serviceability. (Fig.

&Fig. 4-4) Replace a belt that shows signs of severe cuts, tears, separation, weather checking and cracking, or burns caused by slipping. Slight raveling of belt covering does not indicate failure, trim ravelings with a sharp knife.

Inspect the belt pulley grooves and flanges for wear. A new belt, or one in good condition, should never run against the bottom of the groove. Replace the pulley when this is the case, otherwise belt will lose power and slip excessively.

Never pry a belt to get it on a pulley as this will cut or damage the fibers of the belt covering.

Keep oil and grease away from belts and never use belt dressings.

Main drive belt adjustment

1.Park the machine on level ground, disengage traction drive, cutting reel drive, stop engine and disconnect spark plug wire before proceeding with this adjustment. Pull the unit up on the stand.

2.Remove the front cover locking bolt and raise the front cover.

3.Turn the cable lock nut

4.Engage the traction drive lever. The spring should measure 3.38” (86mm) from hook to hook. (Fig.

5.Disengage the traction drive lever.

6.With the traction drive lever disengaged, check to make

Main drive

belts

Fig.

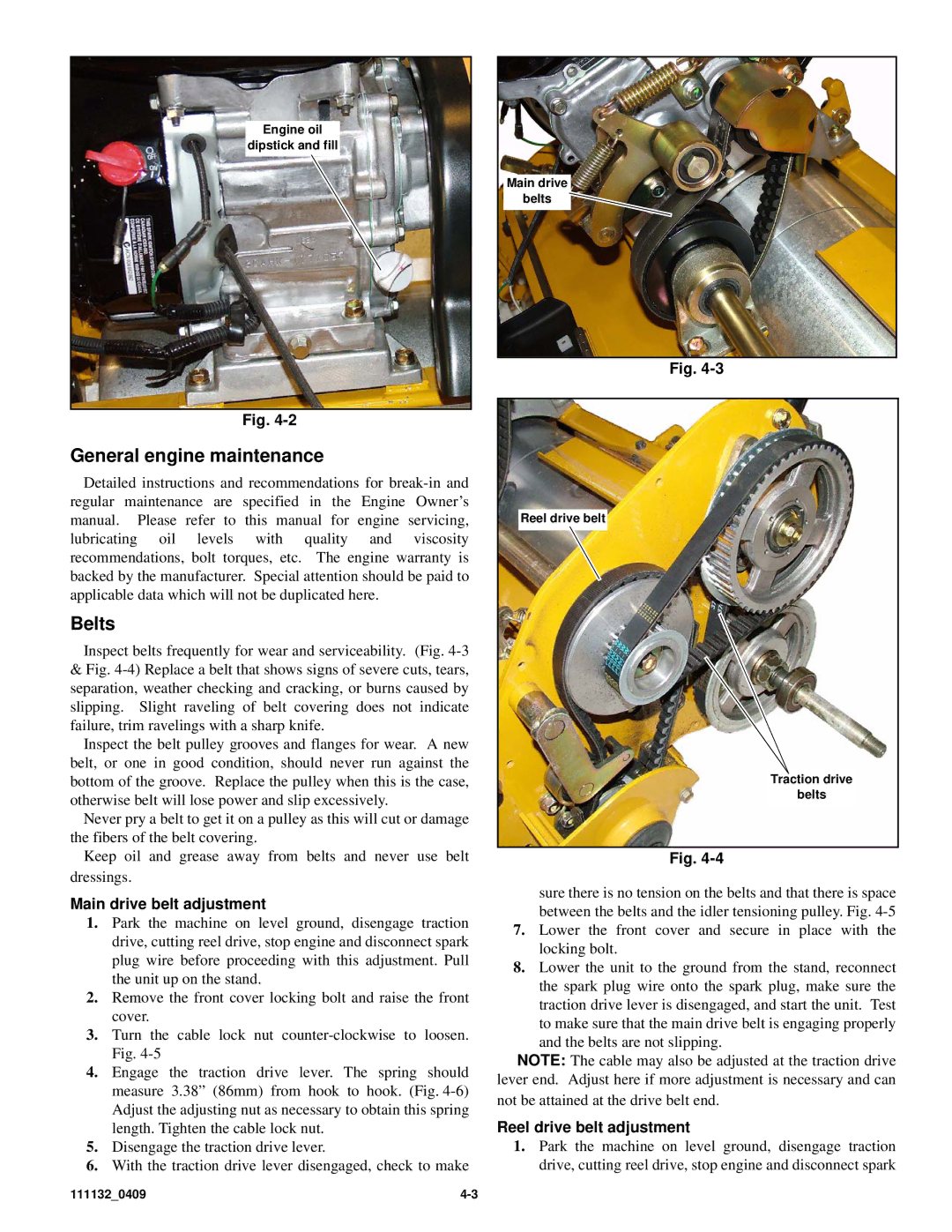

Reel drive belt

Traction drive

belts

Fig.

sure there is no tension on the belts and that there is space between the belts and the idler tensioning pulley. Fig.

7.Lower the front cover and secure in place with the locking bolt.

8.Lower the unit to the ground from the stand, reconnect the spark plug wire onto the spark plug, make sure the traction drive lever is disengaged, and start the unit. Test

to make sure that the main drive belt is engaging properly and the belts are not slipping.

NOTE: The cable may also be adjusted at the traction drive lever end. Adjust here if more adjustment is necessary and can not be attained at the drive belt end.

Reel drive belt adjustment

1.Park the machine on level ground, disengage traction drive, cutting reel drive, stop engine and disconnect spark

111132_0409 |