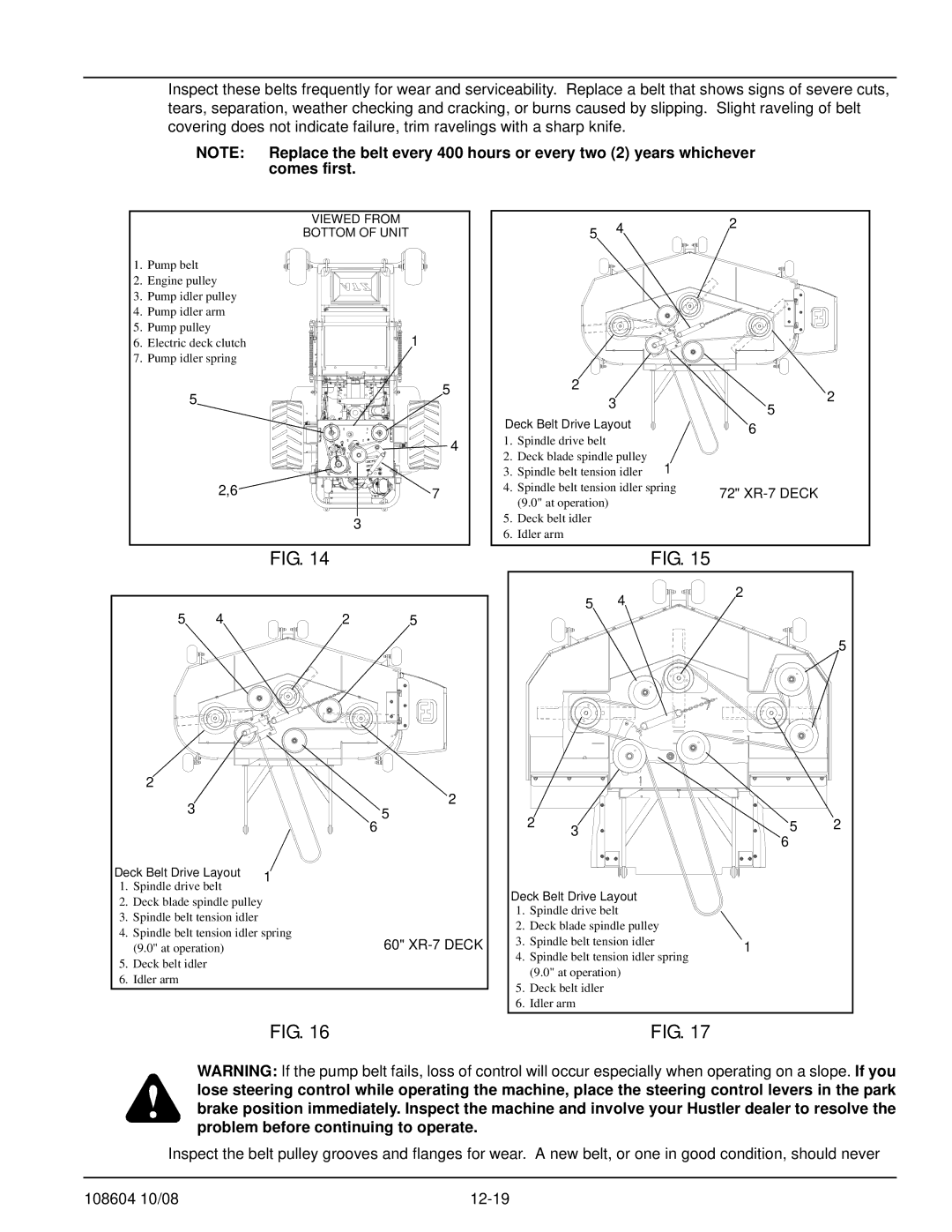

Inspect these belts frequently for wear and serviceability. Replace a belt that shows signs of severe cuts, tears, separation, weather checking and cracking, or burns caused by slipping. Slight raveling of belt covering does not indicate failure, trim ravelings with a sharp knife.

NOTE: Replace the belt every 400 hours or every two (2) years whichever comes first.

|

| VIEWED FROM |

|

| BOTTOM OF UNIT |

1. | Pump belt |

|

2. | Engine pulley |

|

3. | Pump idler pulley |

|

4. | Pump idler arm |

|

5. | Pump pulley | 1 |

6. | Electric deck clutch | |

7. | Pump idler spring |

|

| 5 | 5 |

|

| |

|

| 4 |

| 2,6 | 7 |

|

| 3 |

FIG. 14

| 5 | 4 |

| 2 |

|

|

| ||

|

|

|

| |

| 2 |

|

| 2 |

|

| 3 |

| |

|

|

| 5 | |

Deck Belt Drive Layout |

| |||

| 6 | |||

1. | Spindle drive belt |

|

|

|

2. | Deck blade spindle pulley | 1 |

| |

3. | Spindle belt tension idler |

| ||

4. | Spindle belt tension idler spring | 72" | ||

| (9.0" at operation) |

|

| |

|

|

|

| |

5. | Deck belt idler |

|

|

|

6. | Idler arm |

|

|

|

FIG. 15

| 5 | 4 | 2 | 5 |

| 2 |

|

| 2 |

| 3 |

|

| |

|

|

| 5 | |

|

|

|

| 6 |

Deck Belt Drive Layout | 1 |

| ||

1. | Spindle drive belt |

|

| |

2. | Deck blade spindle pulley |

|

| |

3. | Spindle belt tension idler |

|

| |

4. | Spindle belt tension idler spring | 60" | ||

| (9.0" at operation) |

| ||

5. | Deck belt idler |

|

|

|

6. | Idler arm |

|

|

|

|

| 5 | 4 | 2 |

|

|

|

|

| ||

|

|

|

|

| 5 |

| 2 | 3 |

| 5 | 2 |

|

|

|

| 6 |

|

Deck Belt Drive Layout |

|

| |||

1. | Spindle drive belt |

|

| ||

2. | Deck blade spindle pulley |

|

| ||

3. | Spindle belt tension idler | 1 |

| ||

4. | Spindle belt tension idler spring |

| |||

|

| ||||

| (9.0" at operation) |

|

| ||

5. | Deck belt idler |

|

|

| |

6. | Idler arm |

|

|

| |

FIG. 16 | FIG. 17 |

WARNING: If the pump belt fails, loss of control will occur especially when operating on a slope. If you lose steering control while operating the machine, place the steering control levers in the park brake position immediately. Inspect the machine and involve your Hustler dealer to resolve the problem before continuing to operate.

Inspect the belt pulley grooves and flanges for wear. A new belt, or one in good condition, should never

108604 10/08 |