"Diaphragm Test"

The solution to almost all problems can be found in the paint side valves, due to the increased wear from contact with the abrasive paint/spray materials. Intake valve (ref#

To eliminate the hydraulic side of the pump (piston / oil side of diaphragm) as a source of problems;

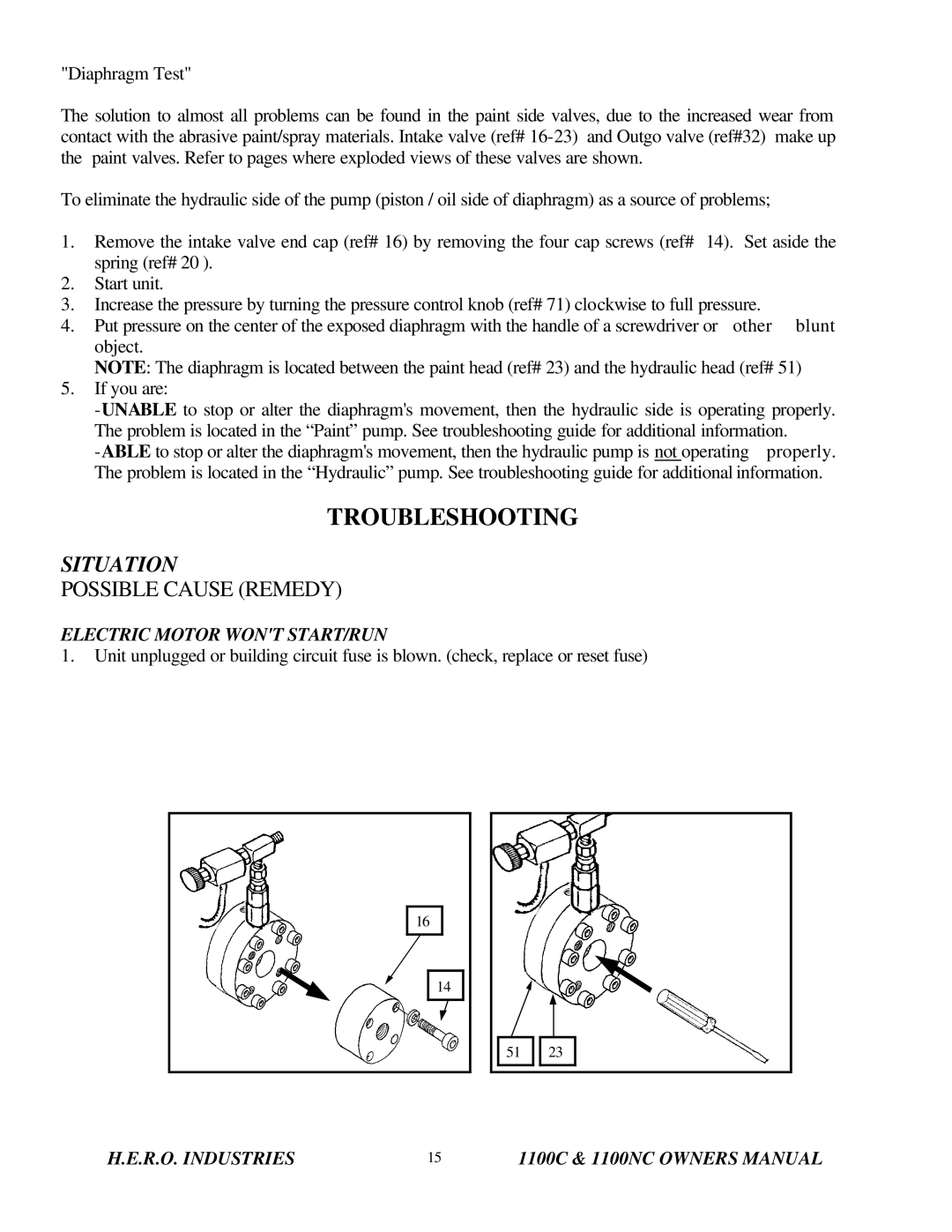

1.Remove the intake valve end cap (ref# 16) by removing the four cap screws (ref# 14). Set aside the spring (ref# 20 ).

2.Start unit.

3.Increase the pressure by turning the pressure control knob (ref# 71) clockwise to full pressure.

4. Put pressure on the center of the exposed diaphragm with the handle of a screwdriver or other blunt object.

NOTE: The diaphragm is located between the paint head (ref# 23) and the hydraulic head (ref# 51)

5.If you are:

TROUBLESHOOTING

SITUATION

POSSIBLE CAUSE (REMEDY)

ELECTRIC MOTOR WON'T START/RUN

1.Unit unplugged or building circuit fuse is blown. (check, replace or reset fuse)

16 |

14 |

51 |

23 |

H.E.R.O. INDUSTRIES | 15 | 1100C & 1100NC OWNERS MANUAL |