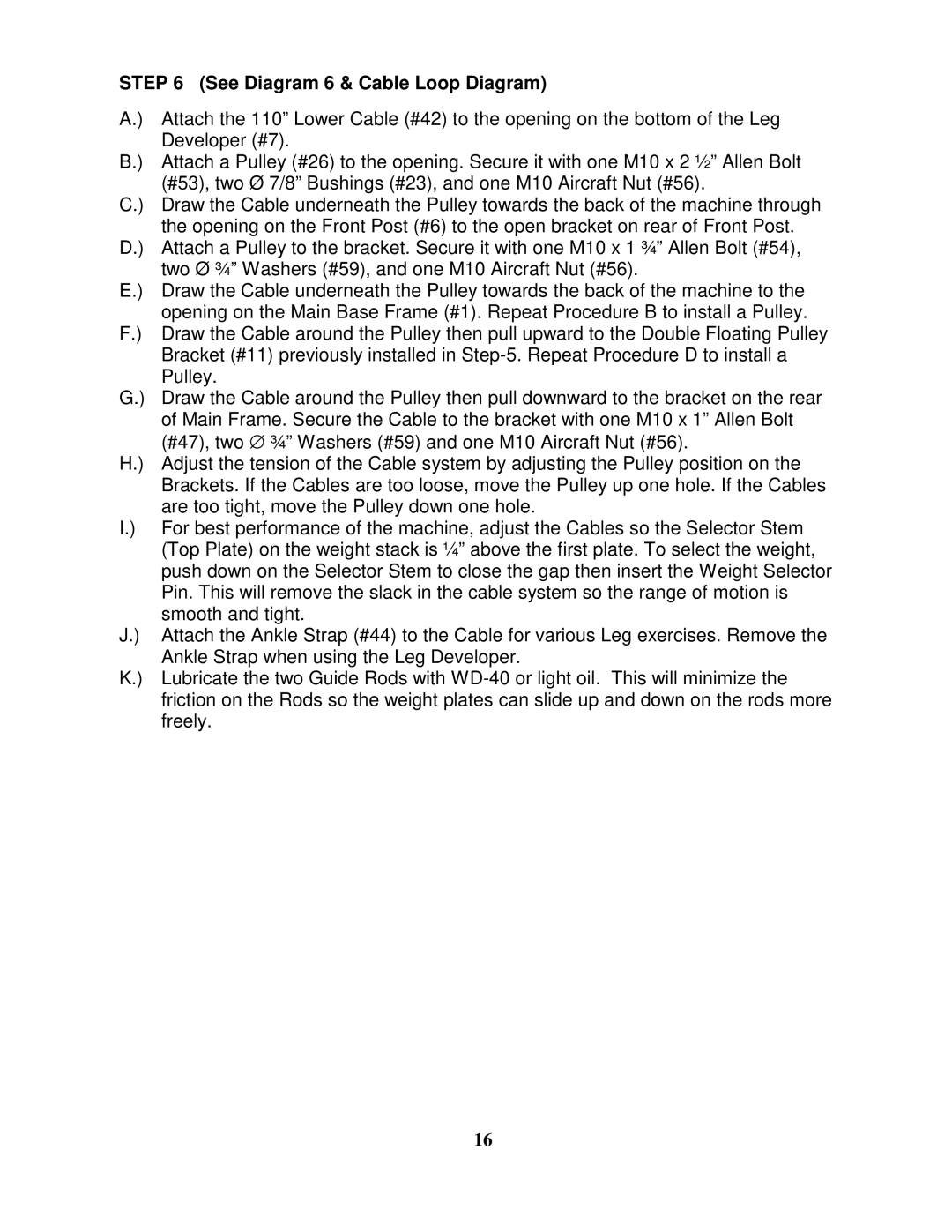

STEP 6 (See Diagram 6 & Cable Loop Diagram)

A.) | Attach the 110” Lower Cable (#42) to the opening on the bottom of the Leg |

| Developer (#7). |

B.) | Attach a Pulley (#26) to the opening. Secure it with one M10 x 2 ½” Allen Bolt |

| (#53), two Ø 7/8” Bushings (#23), and one M10 Aircraft Nut (#56). |

C.) | Draw the Cable underneath the Pulley towards the back of the machine through |

| the opening on the Front Post (#6) to the open bracket on rear of Front Post. |

D.) | Attach a Pulley to the bracket. Secure it with one M10 x 1 ¾” Allen Bolt (#54), |

| two Ø ¾” Washers (#59), and one M10 Aircraft Nut (#56). |

E.) | Draw the Cable underneath the Pulley towards the back of the machine to the |

| opening on the Main Base Frame (#1). Repeat Procedure B to install a Pulley. |

F.) | Draw the Cable around the Pulley then pull upward to the Double Floating Pulley |

| Bracket (#11) previously installed in |

| Pulley. |

G.) | Draw the Cable around the Pulley then pull downward to the bracket on the rear |

| of Main Frame. Secure the Cable to the bracket with one M10 x 1” Allen Bolt |

| (#47), two ∅ ¾” Washers (#59) and one M10 Aircraft Nut (#56). |

H.) | Adjust the tension of the Cable system by adjusting the Pulley position on the |

| Brackets. If the Cables are too loose, move the Pulley up one hole. If the Cables |

| are too tight, move the Pulley down one hole. |

I.) | For best performance of the machine, adjust the Cables so the Selector Stem |

| (Top Plate) on the weight stack is ¼” above the first plate. To select the weight, |

| push down on the Selector Stem to close the gap then insert the Weight Selector |

| Pin. This will remove the slack in the cable system so the range of motion is |

| smooth and tight. |

J.) | Attach the Ankle Strap (#44) to the Cable for various Leg exercises. Remove the |

| Ankle Strap when using the Leg Developer. |

K.) | Lubricate the two Guide Rods with |

| friction on the Rods so the weight plates can slide up and down on the rods more |

| freely. |

16