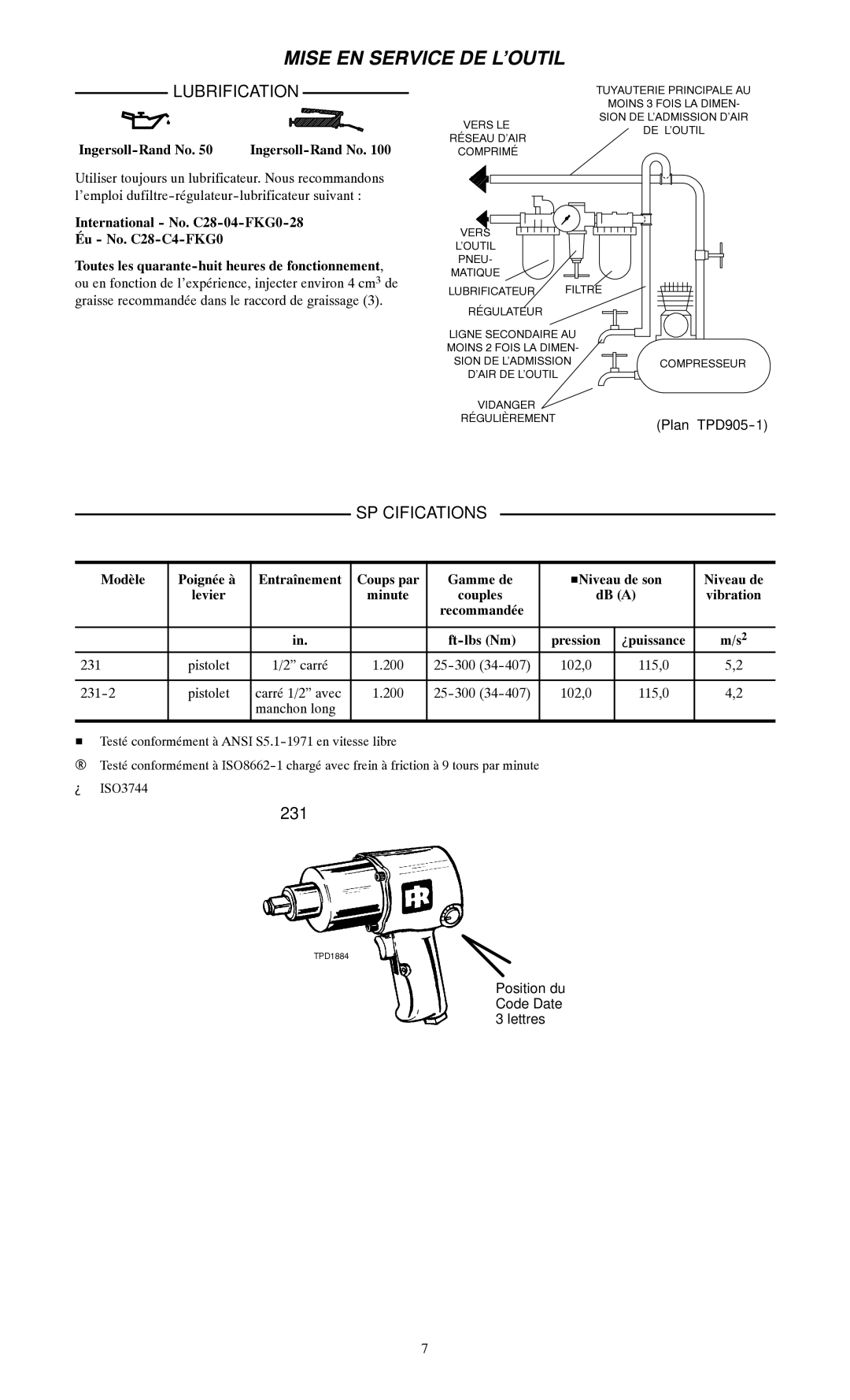

231-2, 231 specifications

The Ingersoll-Rand 231 and 231-2 models represent a high-performance standard in pneumatic tools, specifically in the categories of impact wrenches and air tools. Known for their robust construction and reliable operation, these models are widely utilized in automotive shops, industrial environments, and construction sites where high torque is required.One of the standout features of the Ingersoll-Rand 231 series is its superior power-to-weight ratio. Engineered with a high-efficiency motor, these models deliver impressive torque output without compromising on user comfort. Weighing in at a manageable level, they allow operators to work for extended periods without experiencing excessive fatigue, making them suitable for both professional mechanics and DIY enthusiasts.

The Ingersoll-Rand 231 series boasts a patented twin-hammer mechanism, which enhances its performance by efficiently delivering power to the anvil, leading to rapid nut removal and installation. This technology ensures minimal vibration and noise, contributing to a more comfortable working environment. Moreover, the dual power settings allow users to adjust the torque output according to specific needs, thereby increasing versatility during usage.

Another key characteristic of these tools is their air consumption efficiency. The Ingersoll-Rand 231 models are designed to optimize airflow, ensuring sustained performance even under heavy loads. This efficiency translates into reduced operational costs and the ability to work with smaller compressors without sacrificing power.

Durability is another pillar upon which the 231 series is built. Constructed with heavy-duty materials, including an aluminum housing that resists wear and tear, these tools are designed to withstand the rigors of daily use. Furthermore, the ergonomic design includes a comfortable grip that reduces strain, allowing for precise control during operation.

In summary, the Ingersoll-Rand 231 and 231-2 impact wrenches are reliable, powerful, and user-friendly pneumatic tools tailored for high-demand applications. With their advanced twin-hammer mechanism, superior torque output, and robust construction, these models set a benchmark in the industry. Operators appreciate the balance of strength and weight, while the efficient air consumption and durable build ensure long-lasting performance in various demanding environments.