Inlet Valve Fitting

Removal/Service

This equipment stays pressurized until pressure is manually relieved. To help prevent serious injury from pressurized fluid, such as skin injection, splashing fluid and moving parts, follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or servicing the equipment.

Move sprayer to a

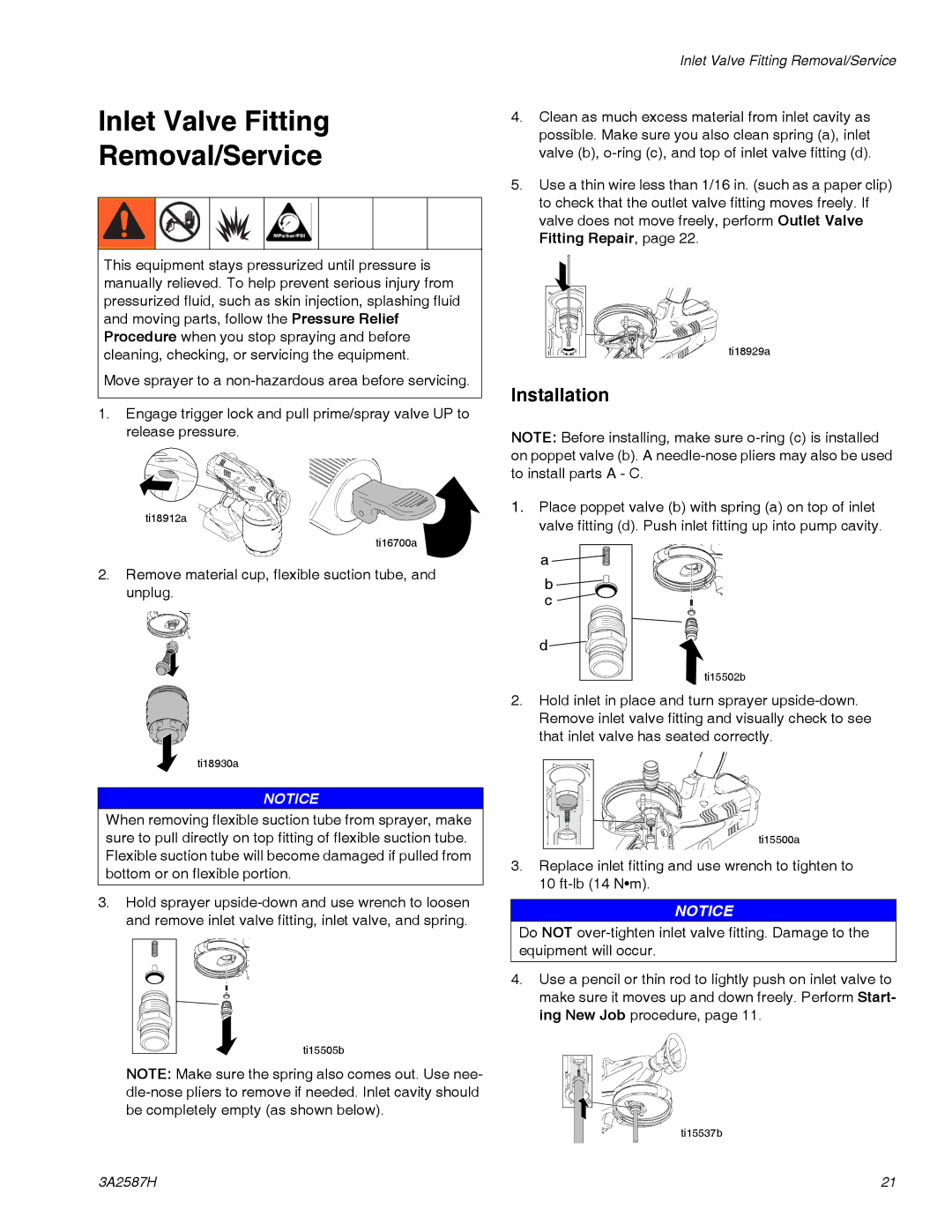

1.Engage trigger lock and pull prime/spray valve UP to release pressure.

ti18912a

ti16700a

2.Remove material cup, flexible suction tube, and unplug.

ti18930a

NOTICE

When removing flexible suction tube from sprayer, make sure to pull directly on top fitting of flexible suction tube. Flexible suction tube will become damaged if pulled from bottom or on flexible portion.

3.Hold sprayer

ti15505b

NOTE: Make sure the spring also comes out. Use nee-

Inlet Valve Fitting Removal/Service

4.Clean as much excess material from inlet cavity as possible. Make sure you also clean spring (a), inlet valve (b),

5.Use a thin wire less than 1/16 in. (such as a paper clip) to check that the outlet valve fitting moves freely. If valve does not move freely, perform Outlet Valve Fitting Repair, page 22.

ti18929a

Installation

NOTE: Before installing, make sure

1.Place poppet valve (b) with spring (a) on top of inlet valve fitting (d). Push inlet fitting up into pump cavity.

a ![]()

![]()

b ![]()

![]()

![]() c

c ![]()

d![]()

![]()

ti15502b

2.Hold inlet in place and turn sprayer

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() ti15500a

ti15500a

3.Replace inlet fitting and use wrench to tighten to 10

NOTICE

Do NOT

4.Use a pencil or thin rod to lightly push on inlet valve to make sure it moves up and down freely. Perform Start- ing New Job procedure, page 11.

ti15537b

3A2587H | 21 |