General Service

See manual 3A1884 (available at www.graco.com) for complete instructions on properly servicing your sprayer.

If you have opened the sprayer clamshell and do not have access to manual 3A1884, follow the instructions below to reduce the risk of errors when assembling the sprayer clamshell.

Wiring

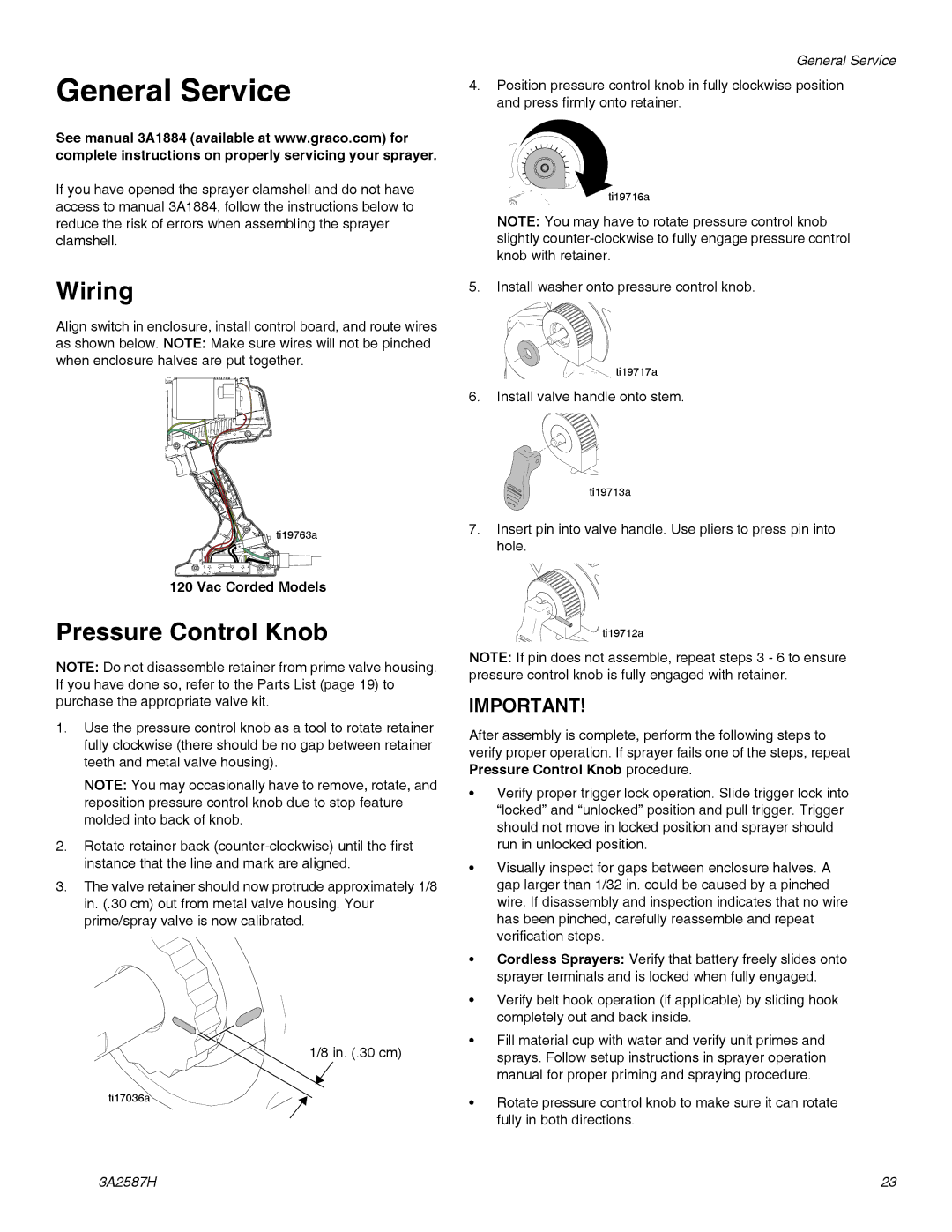

Align switch in enclosure, install control board, and route wires as shown below. NOTE: Make sure wires will not be pinched when enclosure halves are put together.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() ti19763a

ti19763a

120 Vac Corded Models

Pressure Control Knob

NOTE: Do not disassemble retainer from prime valve housing. If you have done so, refer to the Parts List (page 19) to purchase the appropriate valve kit.

1.Use the pressure control knob as a tool to rotate retainer fully clockwise (there should be no gap between retainer teeth and metal valve housing).

NOTE: You may occasionally have to remove, rotate, and reposition pressure control knob due to stop feature molded into back of knob.

2.Rotate retainer back

3.The valve retainer should now protrude approximately 1/8 in. (.30 cm) out from metal valve housing. Your prime/spray valve is now calibrated.

1/8 in. (.30 cm)

ti17036a

General Service

4.Position pressure control knob in fully clockwise position and press firmly onto retainer.

10

ti19716a

NOTE: You may have to rotate pressure control knob slightly

5.Install washer onto pressure control knob.

![]() ti19717a

ti19717a

6.Install valve handle onto stem.

ti19713a

7.Insert pin into valve handle. Use pliers to press pin into hole.

ti19712a

NOTE: If pin does not assemble, repeat steps 3 - 6 to ensure pressure control knob is fully engaged with retainer.

IMPORTANT!

After assembly is complete, perform the following steps to verify proper operation. If sprayer fails one of the steps, repeat Pressure Control Knob procedure.

•Verify proper trigger lock operation. Slide trigger lock into “locked” and “unlocked” position and pull trigger. Trigger should not move in locked position and sprayer should run in unlocked position.

•Visually inspect for gaps between enclosure halves. A gap larger than 1/32 in. could be caused by a pinched wire. If disassembly and inspection indicates that no wire has been pinched, carefully reassemble and repeat verification steps.

•Cordless Sprayers: Verify that battery freely slides onto sprayer terminals and is locked when fully engaged.

•Verify belt hook operation (if applicable) by sliding hook completely out and back inside.

•Fill material cup with water and verify unit primes and sprays. Follow setup instructions in sprayer operation manual for proper priming and spraying procedure.

•Rotate pressure control knob to make sure it can rotate fully in both directions.

3A2587H | 23 |