INSTALLATION

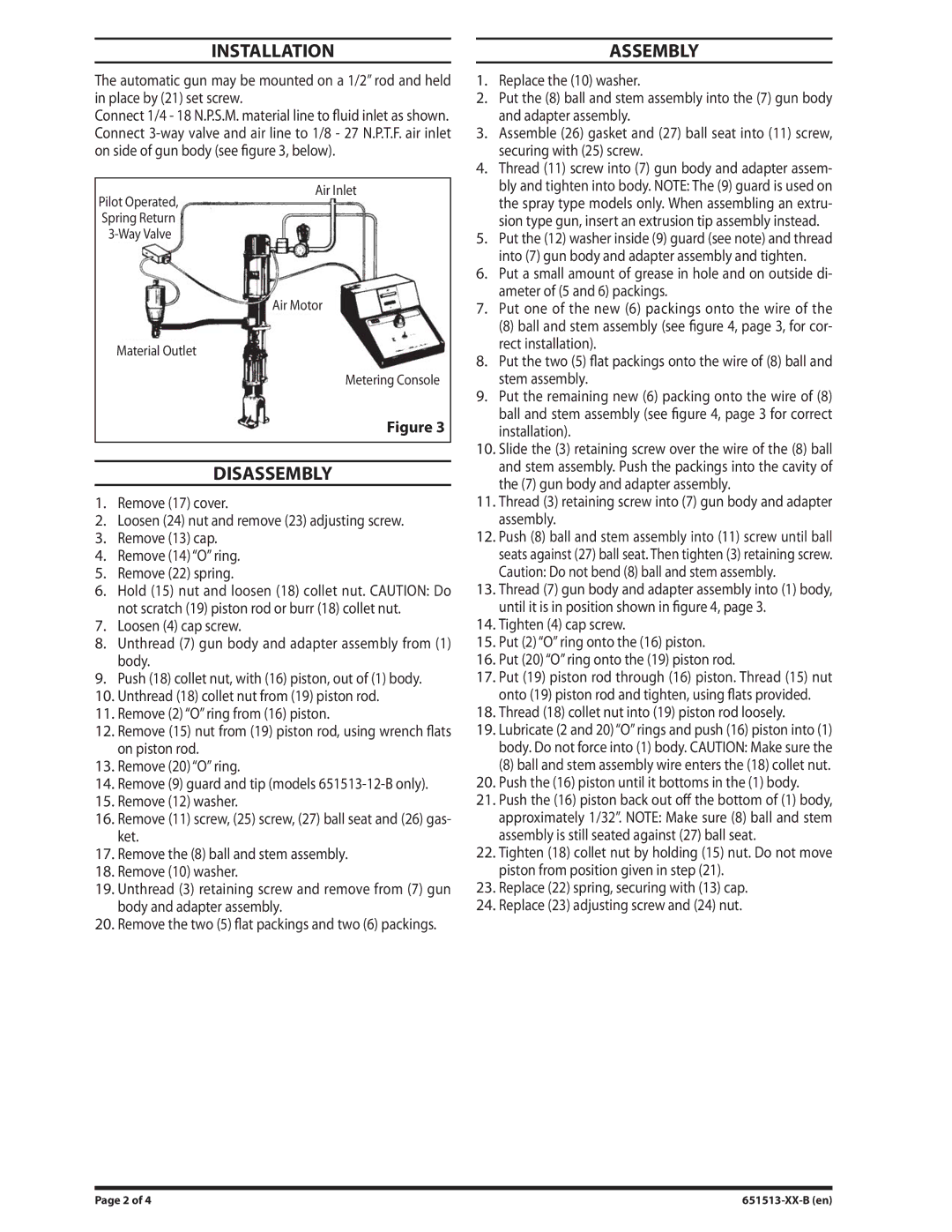

The automatic gun may be mounted on a 1/2” rod and held in place by (21) set screw.

Connect 1/4 - 18 N.P.S.M. material line to fluid inlet as shown. Connect

Air Inlet

Pilot Operated,

Spring Return

Air Motor

Material Outlet

Metering Console

Figure 3

DISASSEMBLY

1.Remove (17) cover.

2.Loosen (24) nut and remove (23) adjusting screw.

3.Remove (13) cap.

4.Remove (14) “O” ring.

5.Remove (22) spring.

6.Hold (15) nut and loosen (18) collet nut. CAUTION: Do not scratch (19) piston rod or burr (18) collet nut.

7.Loosen (4) cap screw.

8.Unthread (7) gun body and adapter assembly from (1) body.

9.Push (18) collet nut, with (16) piston, out of (1) body.

10.Unthread (18) collet nut from (19) piston rod.

11.Remove (2) “O” ring from (16) piston.

12.Remove (15) nut from (19) piston rod, using wrench flats on piston rod.

13.Remove (20) “O” ring.

14.Remove (9) guard and tip (models

15.Remove (12) washer.

16.Remove (11) screw, (25) screw, (27) ball seat and (26) gas- ket.

17.Remove the (8) ball and stem assembly.

18.Remove (10) washer.

19.Unthread (3) retaining screw and remove from (7) gun body and adapter assembly.

20.Remove the two (5) flat packings and two (6) packings.

ASSEMBLY

1.Replace the (10) washer.

2.Put the (8) ball and stem assembly into the (7) gun body and adapter assembly.

3.Assemble (26) gasket and (27) ball seat into (11) screw, securing with (25) screw.

4.Thread (11) screw into (7) gun body and adapter assem- bly and tighten into body. NOTE: The (9) guard is used on the spray type models only. When assembling an extru- sion type gun, insert an extrusion tip assembly instead.

5.Put the (12) washer inside (9) guard (see note) and thread into (7) gun body and adapter assembly and tighten.

6.Put a small amount of grease in hole and on outside di- ameter of (5 and 6) packings.

7.Put one of the new (6) packings onto the wire of the

(8)ball and stem assembly (see figure 4, page 3, for cor- rect installation).

8.Put the two (5) flat packings onto the wire of (8) ball and stem assembly.

9.Put the remaining new (6) packing onto the wire of (8) ball and stem assembly (see figure 4, page 3 for correct installation).

10.Slide the (3) retaining screw over the wire of the (8) ball and stem assembly. Push the packings into the cavity of the (7) gun body and adapter assembly.

11.Thread (3) retaining screw into (7) gun body and adapter assembly.

12.Push (8) ball and stem assembly into (11) screw until ball seats against (27) ball seat. Then tighten (3) retaining screw. Caution: Do not bend (8) ball and stem assembly.

13.Thread (7) gun body and adapter assembly into (1) body, until it is in position shown in figure 4, page 3.

14.Tighten (4) cap screw.

15.Put (2) “O” ring onto the (16) piston.

16.Put (20) “O” ring onto the (19) piston rod.

17.Put (19) piston rod through (16) piston. Thread (15) nut onto (19) piston rod and tighten, using flats provided.

18.Thread (18) collet nut into (19) piston rod loosely.

19.Lubricate (2 and 20) “O” rings and push (16) piston into (1) body. Do not force into (1) body. CAUTION: Make sure the

(8)ball and stem assembly wire enters the (18) collet nut.

20.Push the (16) piston until it bottoms in the (1) body.

21.Push the (16) piston back out off the bottom of (1) body, approximately 1/32”. NOTE: Make sure (8) ball and stem assembly is still seated against (27) ball seat.

22.Tighten (18) collet nut by holding (15) nut. Do not move piston from position given in step (21).

23.Replace (22) spring, securing with (13) cap.

24.Replace (23) adjusting screw and (24) nut.

Page 2 of 4 |