67166-X, 67277-X, 67165-X specifications

Ingersoll-Rand, a leader in industrial and manufacturing technologies, has developed a range of compressed air tools that cater to various sectors. Among these, the models 67165-X, 67166-X, and 67277-X stand out due to their advanced engineering and robust performance.The Ingersoll-Rand 67165-X is designed for heavy-duty applications. This model features a high-efficiency motor that ensures optimal power while minimizing energy consumption. The 67165-X is equipped with a lightweight and durable housing, promoting ease of handling without sacrificing strength. Additionally, its ergonomic design allows for comfortable use over extended periods, reducing operator fatigue. This model is ideal for automotive work, renovation projects, and manufacturing settings where reliability and durability are essential.

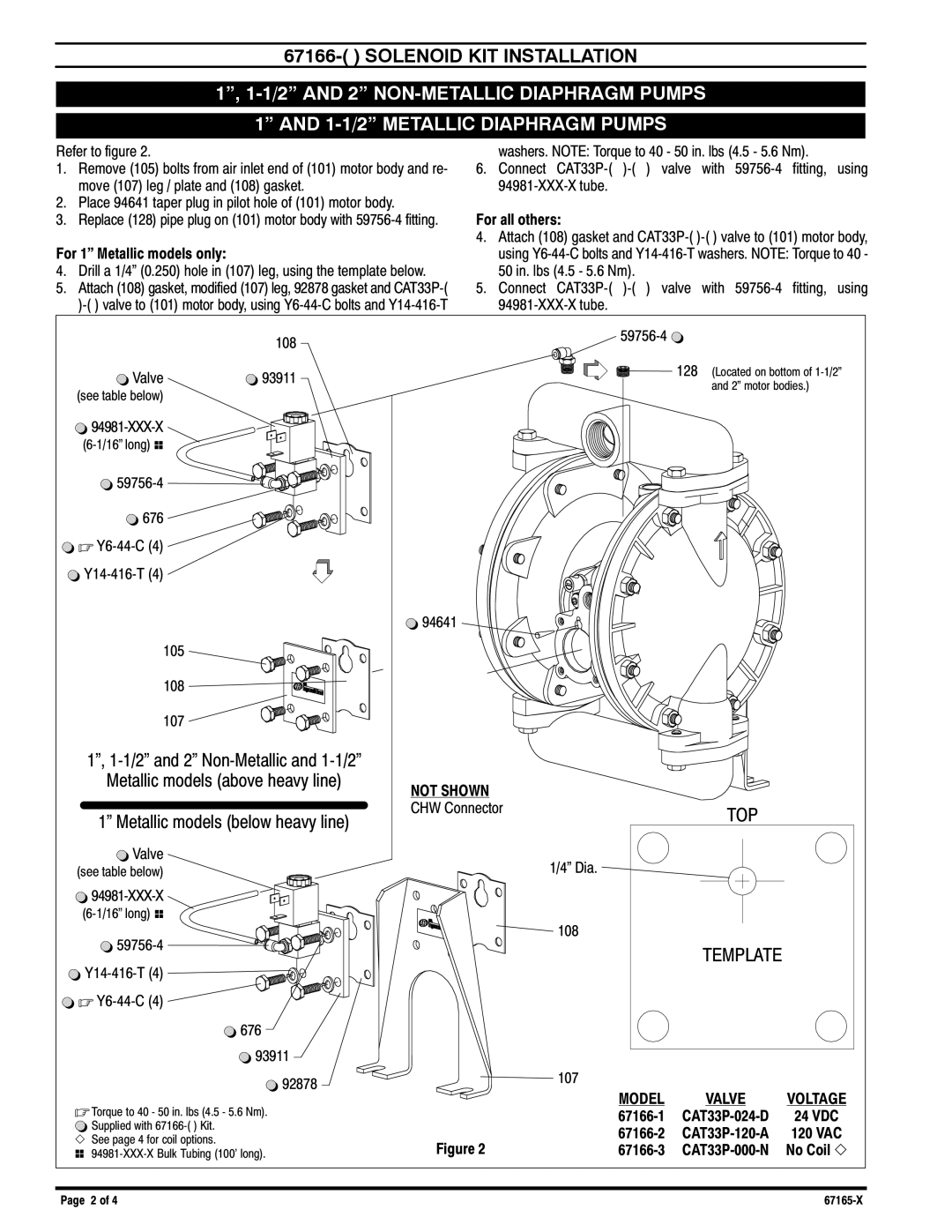

The 67166-X takes performance a step further with its innovative air delivery system. This model features a unique radial blade impeller that enhances airflow and reduces operational noise. The technology incorporated in the 67166-X allows for greater torque output, making it exceptionally effective for fastening applications. The adjustable power settings ensure versatility across various tasks, catering to both delicate and heavy-duty requirements. With a focus on user-friendliness, the 67166-X also integrates a built-in pressure gauge, allowing operators to monitor performance levels at a glance.

Meanwhile, the Ingersoll-Rand 67277-X is an all-around powerhouse known for its high-speed capabilities. This model incorporates advanced materials engineering that contributes to its lightweight yet robust structure. The 67277-X features superior heat dissipation technology, allowing for prolonged use without overheating, making it suitable for high-demand environments. Its quick-release mechanism enhances productivity by enabling rapid tool changes, while the integrated vibration reduction system ensures minimal operator fatigue.

All three models benefit from the company’s commitment to sustainability. Ingersoll-Rand employs eco-friendly manufacturing processes that reduce waste and promote energy efficiency. Furthermore, their durability means lower maintenance frequencies and reduced downtime, improving overall operational efficiency.

In summary, the Ingersoll-Rand 67165-X, 67166-X, and 67277-X models are engineered with cutting-edge technologies that enhance performance, durability, and user comfort. Whether in automotive workshops, construction sites, or manufacturing facilities, these tools offer the reliability and efficiency that professionals depend on.