OPERATOR’S MANUAL | |

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE | |

| |

| |

|

electronic interface

for Diaphragm Pumps

RELEASED:

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

PUMP DATA

general description

This manual is supplemental information for the electronic interface options on the PE series of pumps. For complete pump installation, disassembly and reassembly, safety infor- mation, and other general pump information, please refer to the PD pump manual that was also included with the pump. This electronic interface includes options for solenoid control, end of stroke feedback, leak detection (diaphragm failure), cycle counting on the major valve, and a ported motor with no major valve for

Solenoid control allows the cycle rate of the pump to be con- trolled electronically.

With Solenoid control, when the solenoid is energized, the pump strokes and dispenses the fluid in one chamber. When the solenoid is

By providing continuous ON - OFF signals to the solenoid, the fluid transfer rate may be increased or decreased remotely. End of stroke feedback can be used in conjunction with the solenoid valve to cycle the pump based upon completion of each stroke.

The leak detection option incorporates an optical fluid sensor in each air chamber to provide a signal when a diaphragm has failed and fluid is leaking through the pump.

The cycle counter option provides a closed contact output each time the pump completes a cycle. This option is not available combined with solenoid control.

The ported motor with no major valve is provided as an op- tion for users who want to supply compressed air directly to each diaphragm and control the operation of the pump with their own external air controls.

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) | © 2013 | CCN 46750816 |

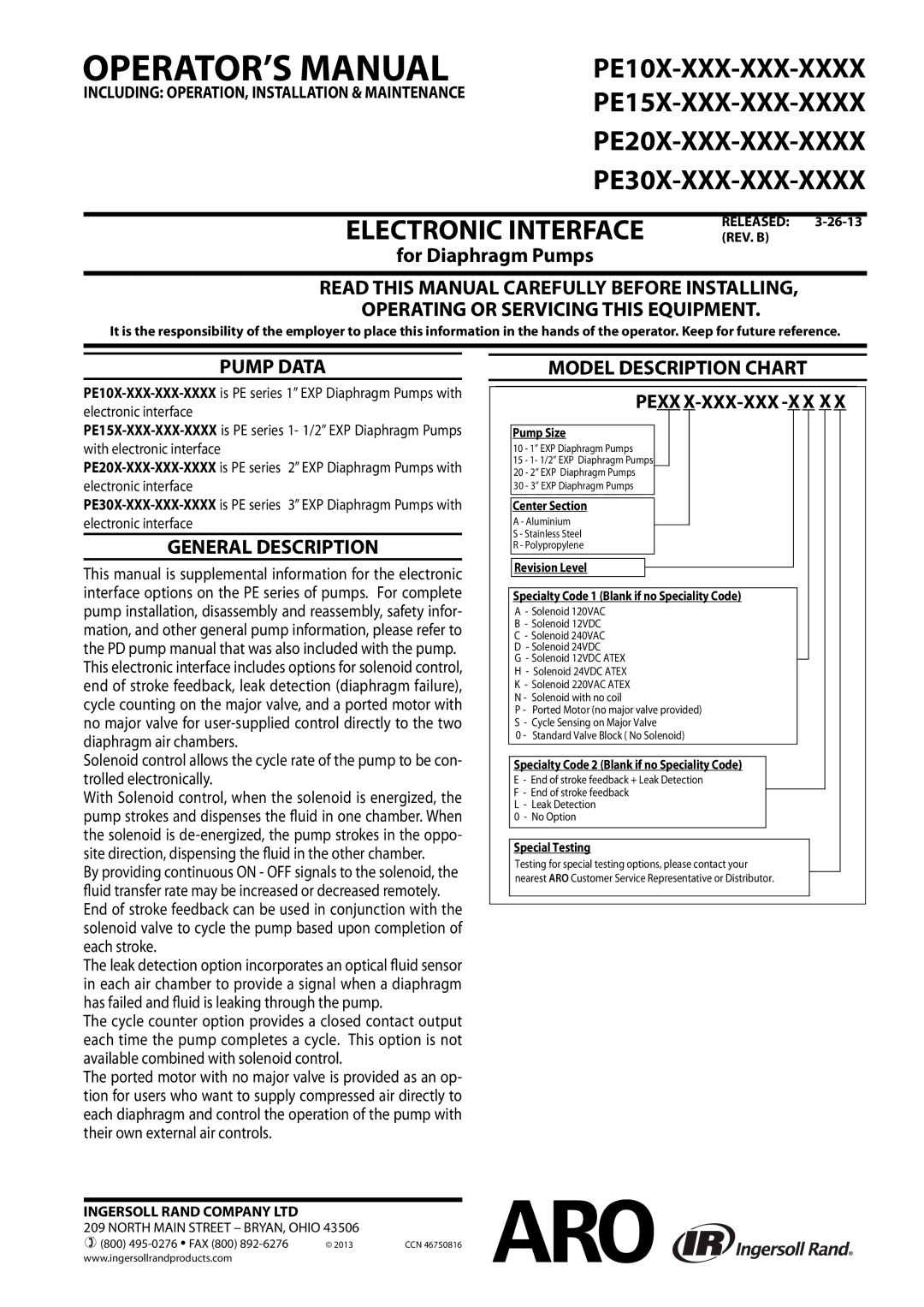

MODEL DESCRIPTION CHART

PEXX X-XXX-XXX -X X X X

Pump Size

10 - 1” EXP Diaphragm Pumps

15 - 1- 1/2” EXP Diaphragm Pumps

20 - 2” EXP Diaphragm Pumps

30 - 3” EXP Diaphragm Pumps

Center Section

A - Aluminium

S - Stainless Steel

R - Polypropylene

Revision Level

Specialty Code 1 (Blank if no Speciality Code)

A - Solenoid 120VAC

B - Solenoid 12VDC

C - Solenoid 240VAC

D - Solenoid 24VDC

G - Solenoid 12VDC ATEX

H- Solenoid 24VDC ATEX K - Solenoid 220VAC ATEX N - Solenoid with no coil

P - Ported Motor (no major valve provided) S - Cycle Sensing on Major Valve

0 - Standard Valve Block ( No Solenoid)

Specialty Code 2 (Blank if no Speciality Code)

E- End of stroke feedback + Leak Detection

F- End of stroke feedback

L - Leak Detection

0 - No Option

Special Testing

Testing for special testing options, please contact your nearest ARO Customer Service Representative or Distributor.

www.ingersollrandproducts.com