SAFE OPERATING INSTRUCTIONS

The following warnings and operating instructions have been adapted in part from American National Standard ASME B30.21 and are intended to avoid unsafe operating practices which might lead to injury or property damage.

Ingersoll Rand recognizes that most companies who use hoists have a safety program in force in their plants. In the event that some conflict exists between a rule set forth in this publication and a similar rule already set by an individual company, the more stringent of the two should take precedence.

Safe Operating Instructions are provided to make an operator aware of dangerous practices to avoid and are not necessarily limited to the following list. Refer to specific sections in the manual for additional safety information.

1.Only allow personnel trained in safety and operation of this product to operate hoist.

2.Only operate a hoist if you are physically fit to do so.

3.When a “DO NOT OPERATE” sign is placed on hoist, do not operate hoist until sign has been removed by designated personnel.

4.Before each shift, the operator should inspect hoist for wear or damage.

5.Never use a hoist which inspection indicates is worn or damaged.

6.Periodically, inspect hoist thoroughly and replace worn or damaged parts. Refer to “INSPECTION” section.

7.Lubricate hoist regularly. Refer to “LUBRICATION” section.

8.Do not use hoist if hook latch has been sprung or broken.

9.Check that hook latches are engaged before using.

10.Never splice a hoist chain by inserting a bolt between links.

11.Only lift loads less than or equal to rated capacity of hoist. Refer to “SPECIFICATIONS” section.

12.Never use hoist load chain as a sling.

13.Never operate a hoist when load chain is not centered under top hook. Do not “side pull” or “yard.”

14.Never operate a hoist with twisted, kinked, “capsized” or damaged load chain.

15.Do not force a chain or hook into place by hammering.

16.Never insert point of hook into a chain link.

17.Be certain load is properly seated in saddle of hook and hook latch is engaged.

18.Do not support load on tip of hook.

19.Never run load chain over a sharp edge. Use a sheave.

20.When using two hoists to suspend one load, select two hoists each having a rated capacity equal to or more than the load. This provides adequate safety in the event of a sudden load shift.

21.Pay attention to the load at all times when operating hoist.

22.Always ensure that you, and all other people, are clear of load path. Do not lift a load over people.

23.Never use hoist for lifting or lowering people, and never allow anyone to stand on a suspended load.

24.Ease slack out of chain and sling when starting a lift. Do not jerk the load.

25.Do not swing a suspended load.

26.Do not leave a load suspended when hoist is unattended or not in use.

27.Never weld or cut on a load suspended by the hoist.

28.Never use hoist chain as a welding electrode.

29.Do not operate hoist if chain jumping, excessive noise, jamming, overloading, or binding occurs.

30.Keep load from hitting load chain.

31.Do not use a cheater bar or extended handle.

32.Never place hand inside throat area of a hook.

33.After use, or when in a

34.Only operate hoist with manual power.

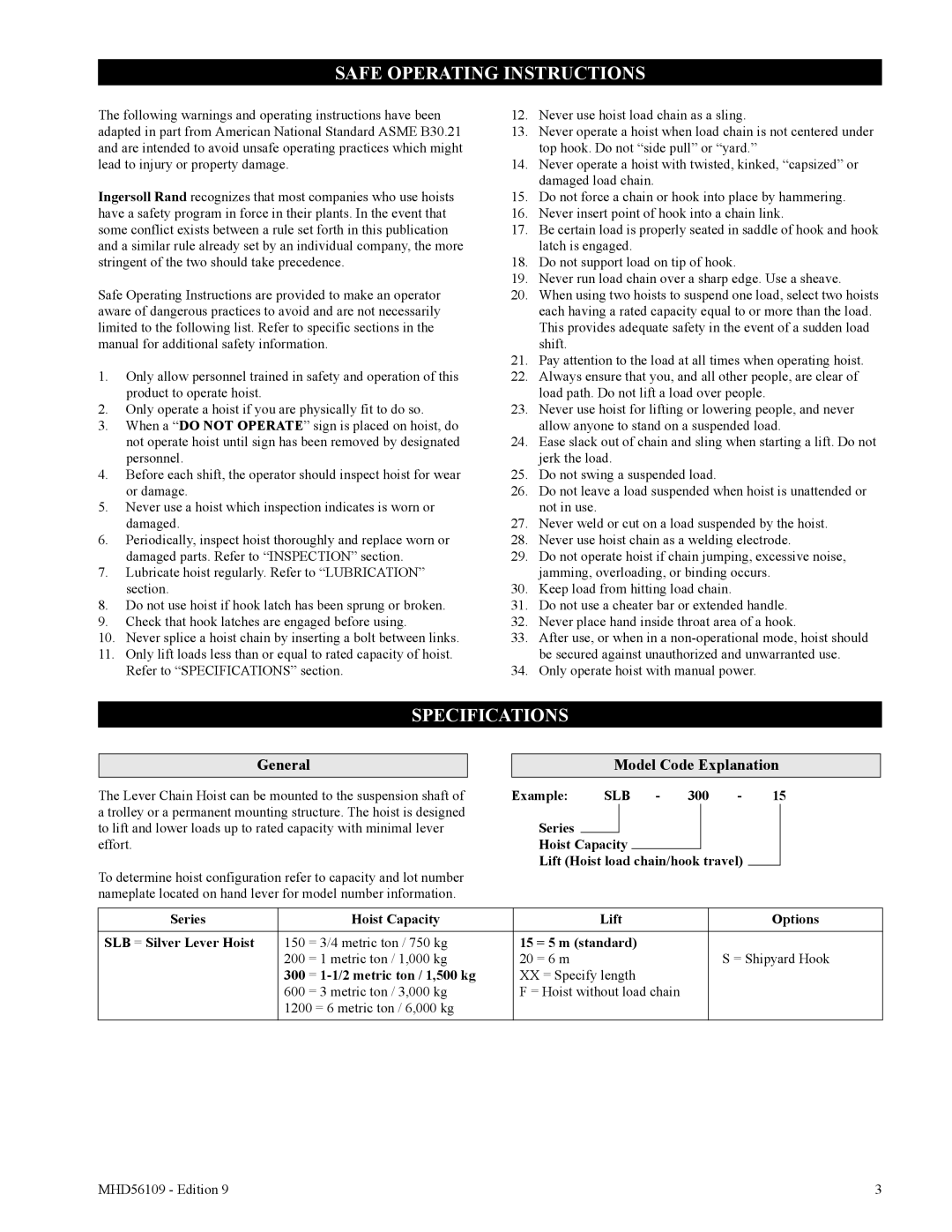

SPECIFICATIONS

General

The Lever Chain Hoist can be mounted to the suspension shaft of a trolley or a permanent mounting structure. The hoist is designed to lift and lower loads up to rated capacity with minimal lever effort.

To determine hoist configuration refer to capacity and lot number nameplate located on hand lever for model number information.

Model Code Explanation

Example: SLB - 300 - 15

Series

Hoist Capacity

Lift (Hoist load chain/hook travel)

Series |

| Hoist Capacity |

| Lift | Options |

|

|

|

|

| |

SLB = Silver Lever Hoist | 150 = 3/4 metric ton / 750 kg | 15 | = 5 m (standard) |

| |

| 200 | = 1 metric ton / 1,000 kg | 20 | = 6 m | S = Shipyard Hook |

| 300 | = | XX = Specify length |

| |

| 600 | = 3 metric ton / 3,000 kg | F = Hoist without load chain |

| |

| 1200 = 6 metric ton / 6,000 kg |

|

|

| |

|

|

|

|

|

|

MHD56109 - Edition 9 | 3 |