ld | :(0] | II | : II:l"l_'[*Ia]l | d I_ [{glm |

|

|

|

|

|

|

|

|

| m,_ |

|

|

|

|

|

|

|

|

|

|

|

| |||

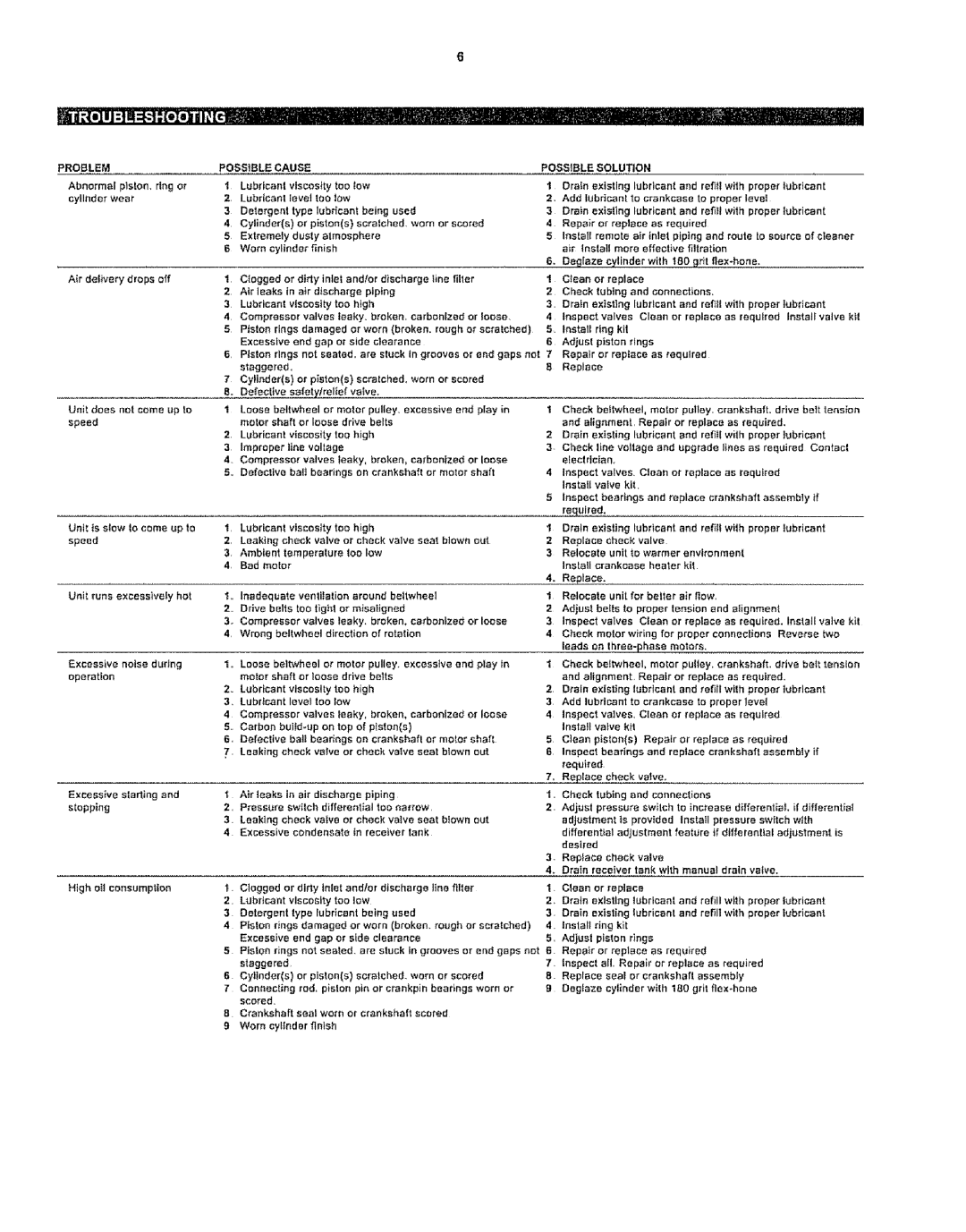

PROBLEM |

|

|

| POSSIBLE | CAUSE |

|

|

|

|

|

|

|

| POSSIBLE | SOLUTION |

|

|

|

|

|

|

| |||||||

Abnormal | piston, | ring or | 1 | Lubricant | viscosity | too tow |

|

|

|

| 1 | Drain | existing | lubricant | and | refill with proper | lubricant | ||||||||||||

cylinder | wear |

| 2 | Lubricant | level | too | law |

|

|

|

|

|

| 2, | Add | lubricant | to crankcase | to proper | levet |

| |||||||||

|

|

|

|

| 3 | Detergent | type | lubricant | being | used |

|

| 3 | Drain | existing | lubricant | and | refill with | proper | lubricant | |||||||||

|

|

|

|

| 4 | Cylinder(s) | or piston(s) |

| scratched, | worn or scored | 4 | Repair or replace | as required |

|

|

| |||||||||||||

|

|

|

|

| 5 | Extremely | dusty atmosphere |

|

|

|

| 5 | Install | remote | air | inlet piping | and | route to source of cleaner | |||||||||||

|

|

|

|

| 6 | Worn | cylinder | finish |

|

|

|

|

|

|

|

| air | Installmore effective | filtration |

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 6. | Det'_lezecylinder | with | 180 grit |

| |||||||

Air | delivery drops | off | 1 | Ctogged | or dirty inlet and/or discharge | line fitter | 1 | Clean | or reptace |

|

|

|

|

|

|

| |||||||||||||

|

|

|

|

| 2 | Atr leaks | tn air | discharge | piping |

|

|

|

| 2 | Check | tubing | and | eonnecttonm |

|

|

| ||||||||

|

|

|

|

| 3 | Lubricant | viscosity | too | high |

|

|

|

| 3 | Drain | existing | lubricant | and | refIlf | with | proper | lubricant | |||||||

|

|

|

|

| 4 | Compressor | valves | leaky, broken, | carbonized | or Ioose. | 4 | tnspect valves | Clean | or | replace | as required | Installvalve kit | ||||||||||||

|

|

|

|

| 5 | Piston | rings | damaged | or worn | (broken. | rough | or scratched) | 5 | Install | ring kit |

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

| Excessive | end gap or side clearance |

|

| 6 | Adjust | piston rings |

|

|

|

|

|

| |||||||||||

6Piston rings not seated, are stuck In grooves or end gaps not 7 Repair or replace as required

staggered, | 8 Replace |

7Cylinder(s) or piston(s) scratched_ worn or scored

8.Defective safety/relief vatve.

U_it does | not | come | up | to | 1 | Loose | beltwheel |

| or motor | pulfey, | excessive | end play | in | t | Check | beflwheel, | motor | pulley, | crankshaft, drive bett ter_sSen | ||||||||||||||||||||||||||||

speed |

|

|

|

|

|

| motor shaft or loose drive belts |

|

|

|

|

|

|

|

| and alignment, |

| Repair or replace as required, |

|

|

|

| |||||||||||||||||||||||||

|

|

|

|

|

| 2. | Lubricant | viscosity | tea | high |

|

|

|

|

|

|

|

| 2 | Drain | existing | lubricant | and | retill | wilh | proper | lubricant |

| |||||||||||||||||||

|

|

|

|

|

| 3 | Improper | line voltage |

|

|

|

|

|

|

|

|

|

|

| 3. | Check | line | voltage and upgrade | lines | as | required | Contact | ||||||||||||||||||||

|

|

|

|

|

| 4 | Compressor | valves | leaky, | broken, | carbonized | or loose |

| electrician. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||

|

|

|

|

|

| S, | Defective | bait bearings | on crankshaft |

| or | motor | shaft |

| 4 | Inspect | valves, |

| Clean | or replace | as | required |

|

|

|

|

| ||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Install | valve | kit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5 | Inspect | bearings | and replace |

| crankshaft | assembly | If |

| ||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| required, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Unit ts slow Io | come up | to | 1 | Lubricant | vtscosttytoo |

| high |

|

|

|

|

|

|

|

| I | Drain | existing | lubricant | end | refiltwith | proper | lubricant |

| |||||||||||||||||||||||

speed |

|

|

|

|

| 2, | Leaking check | valve or | check valve seat blown out |

| 2 | Replace | check |

| valve |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||

|

|

|

|

|

| 3, | Ambient |

| temperature | too | low |

|

|

|

|

|

|

|

| 3 | Relocate | unit | to warmer | environment |

|

|

|

|

|

|

|

| |||||||||||||||

|

|

|

|

|

| 4 | Bad motor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Install | crankcase | healer | kit |

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4. | _lace. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Unit runs excessively | hot | 1, | Inadequate | venlilation |

| around | bettwheel |

|

|

|

| 1 | Relocate | unit | for belier | air | now |

|

|

|

|

|

|

|

|

|

| ||||||||||||||||||||

|

|

|

|

|

| 2 | Drive belts | Ioo | tight | or misaligned |

|

|

|

|

|

|

| 2 | Adjust | belts |

| to proper | tension | and | alignment |

|

|

|

|

| |||||||||||||||||

|

|

|

|

|

| 3, | Compressor | valves | leaky, | broken, | carbonized | or loose | 3 | Inspect | valves |

| Clean | or | replace | as required, Install valve kit | |||||||||||||||||||||||||||

|

|

|

|

|

| 4, | Wrong | beltwheel | direction | of rotation |

|

|

|

|

|

| 4 | Cheek | motor | wiring for | proper | connections | Reverse | two | |||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| leads on |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

Excessive | noise | durtng |

| 1, | Loose | beltwheel |

| or motor | pulley, | excessive | and play | In | t | Check | beltwheal, | motor | pulley, | crankshaft, drive | belt | tension | |||||||||||||||||||||||||||

operation |

|

|

|

|

| 2, | meter shaft or loose drive belts |

|

|

|

|

|

|

|

| and alignment |

| Repair or replace as required, |

|

|

|

| |||||||||||||||||||||||||

|

|

|

|

|

| Lubricant | viscosity | too | high |

|

|

|

|

|

|

|

| 2 | Drain | existing | lubricant | and | refill | wilh | proper | lubricant |

| ||||||||||||||||||||

|

|

|

|

|

| 3, | Lubricant level | too few |

|

|

|

|

|

|

|

|

|

| 3 | Add lubricant |

| to crankcase | 1oproper | level |

|

|

|

|

| ||||||||||||||||||

|

|

|

|

|

| 4 | Compressor | valves | leaky, | broken, | carbonized | or loose | 4 | Inspect | valves, |

| Clean | or | replace | as | required |

|

|

|

|

| |||||||||||||||||||||

|

|

|

|

|

| 5, | Carbon |

| on | top | of | piston(s) |

|

|

|

|

|

|

| Install | vatve | kit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

| 6, | Defective | ball bearings | on crankshaft |

| or | motor | shaft |

| 5 | Clean | piston(s) |

| Repair | or | replace | as | required |

|

|

|

| ||||||||||||||||||||

|

|

|

|

|

| .7 | Leaking |

| check | valve | or | check | valve | seat | blown | out |

| 6 | Inspect | bearings | end replace |

| crankshaft | ascambly | if |

| |||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| required |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 7. | Replace | check |

| valve, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

Excessive | starting | and |

| t | Air leaks | te ai_r discharge | piping |

|

|

|

|

|

|

| 1 | Check | tubing |

| and connections |

|

|

|

|

|

|

|

|

|

| ||||||||||||||||||

stepping |

|

|

|

|

| 2 | Pressure | switch |

| differential | too narrow |

|

|

|

|

| 2 | Adjust | pressure | switch | to | increase |

| differential | if differential | ||||||||||||||||||||||

|

|

|

|

|

| 3 | Leaking | check | valve or check | valve | seat | blown | out |

|

| adjustment | ls | provided |

| tnstatl | pressure | switch | with |

|

| ||||||||||||||||||||||

|

|

|

|

|

| 4 | Excessive | condensate |

| tn receiver | tank |

|

|

|

|

| differential | adjustment | feature | tf differential | adjustment | is | |||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| desired |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3 | Replace | cheek | valve |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4. | Drain | receiver | tank with manual | drain | valve, |

|

|

|

|

| ||||||||||||

High ellconsumption |

|

| t | Clogged | or | dirty | inlet | and/or discharge | llne | triter |

| 1 | Clean | or replace |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||

|

|

|

|

|

| 2 | Lubricant viscosity toolow |

|

|

|

|

|

|

|

|

| 2, | Drain | existing | lubricant | and | refill | w_th proper | lubricant |

| ||||||||||||||||||||||

|

|

|

|

|

| 3 | Detergent | type |

| lubricant | being | used |

|

|

|

|

|

| 3 | Drain | existing | lubricant | and | refill | with proper | lubricant |

| ||||||||||||||||||||

|

|

|

|

|

| 4 | Piston | flags | damaged | or worn | (broken. | rough | or scratched) | 4 | Install | ring | kit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

|

|

|

|

|

|

| Excessive | end gap or side clearance |

|

|

|

|

|

| 5, | Adjust | piston | rings |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||

5Pislon rings not seated, are stuck tn grooves or end gaps not 6 Repair or replace as required

| staggered |

|

|

| 7 | Inspect | all Repair or replace | as required | |

6 | Cylinder(s) | or piston(s) | scratched, worn | or scored | 8 | Replace | seal or | crankshaft assembly | |

7 | Connecting | red, piston | pin or crankpin | bearings worn or | g | Deg_aze | cylinder | wlth 180 grit | |

scored

B Crankshaft seat worn or crankshaft scored 9 Worn eytinderftnish