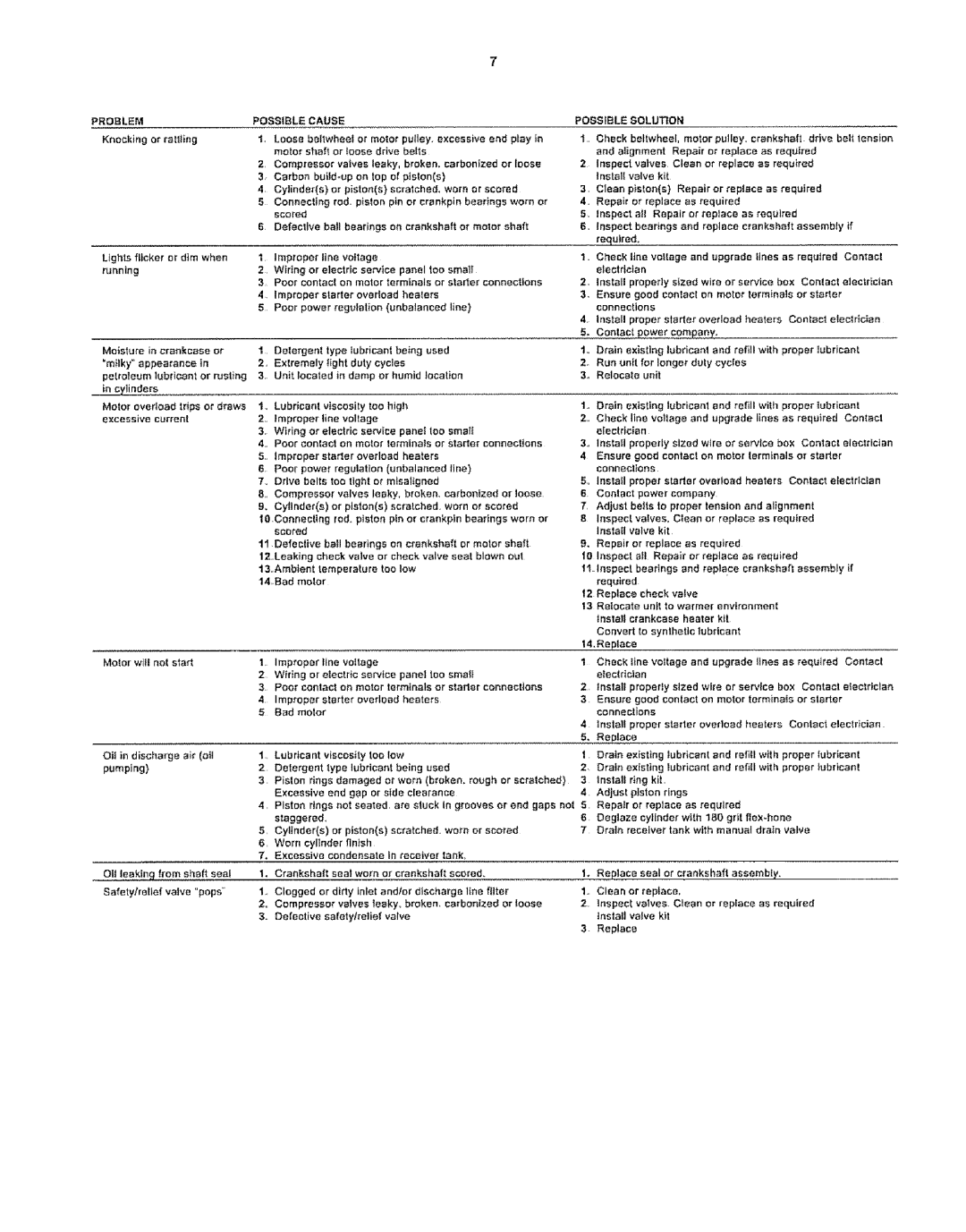

PROBLEM | POSSIBLE | CAUSE |

|

|

|

|

|

|

|

|

| ||

Knocking or retlting | t, | Loose | beltwheel | or | motor | pulley, | excessive | end | play | in | |||

|

| motor | shaft | or | loose | drive | belts |

|

|

|

|

| |

| 2 | Compressor | valves | leaky, | broken, | carbonized | or | loose |

| ||||

| 3, | Carbon | on | top | elf | piston(s) |

|

|

|

|

| ||

| 4 | Cylindei'{s} | or | piston(s) | scratched, | warn | or scared |

|

| ||||

| 5 | Connecting | rod, piston | pin | or crankpln | bearings | worn | or | |||||

|

| scored |

|

|

|

|

|

|

|

|

|

|

|

6Defective ball bearings er_ crankshaft or motor shaft

POSSIBLE SOLUTION

lCheck beltwheel, motor pufiey, crankshaft drive bell tension and alignment Repair or replace as required

2 lnspectvatves Clean or repleee as required install valve kit

3Clean plston{s) Repair or replace as required 4, Repair or replace as required

5inspect all Repair or replace as required

6, inspect bearings and replace crankshaft assembly tf required.

Lights flicker or dim when | 1 | Improper ttne voltage |

|

|

| 1 | Check | line re!rage and apgrade lines as required | Contacl | |||||||

running | 2 | Wiring | or electric | service panel | too | small |

| electrician |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| ||||||||

| 3 | Poor | contact on | motor | terminals | or | starter connections | 2 | install | properly | sized | wire or service box Contact | electrician | |||

| 4 | lmproperstarterovedoad | healers |

| 3, | Ensure | good | contact | on motor | terminals | or starter |

| ||||

| 5 | Poor power regulation | (unbalanced | line) | 4, | connections |

|

| overload | heaters |

|

| ||||

|

|

|

|

|

|

|

| install | proper | starter | Contact eleclrician | |||||

|

|

|

|

|

|

|

| 5, | Contact | power | company, |

|

|

| ||

Moisture in crankcase or

"milky" appearance in pelroleum lubricant or rusling

in cylinders

tDetergent type lubricant being used 2, Extremely tight duty cycles

3.Unit located in damp or humid location

t, Drain exisling lubricanl and refill with proper lubricant

2.Run unit for longer duty cycles 3,, Relocate unit

Motor ovedoad trips or draws excessive current

1, | Lubricant | viscosity too | high |

|

|

|

|

| i, | Drain existing | lubricant | and refill | with | proper | lubricant | |||||||||||||||

2. | tmproper |

| line | voltage |

|

|

|

|

|

|

| 2, | Check | line | voltage and | upgrade | lines | as | required | Contact | ||||||||||

3 | Wiring or | electric | service | panet | toe | smeIt |

|

|

| electrician |

|

|

|

|

|

|

|

|

|

|

| |||||||||

4o | Poor | contact on | motor | lerminats | or starter | connections | 3,, | Instafl | properly sized | w_re or service | box | Contact | electrician | |||||||||||||||||

5,, | tmproper |

| starter | evedoad | heaters |

|

|

|

| 4 | Ensure |

| good contacl | on motor | lerminats | or | starter |

| ||||||||||||

6. | Poor | power | regulation | (unbalanced |

| line) |

|

|

| connections |

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

| proper |

|

| ovedcad |

|

|

|

|

|

| ||||||||||||||||

7, | Drive | belts | too tight | or misaligned |

|

|

|

| 5, | Install | starter | heaters | Contact electrician | |||||||||||||||||

8,, | Compressor | valves | leaky, | broken, | carbonized | or loose | 6 | Contact |

| power | company |

|

|

|

|

|

|

| ||||||||||||

9. | Cylinder(s) | or piston(s) | scratche& | worn or scored | 7 | Adjust | begs | lo | proper | tension | and alignment |

|

| |||||||||||||||||

t0,Oonnecttng |

| rod, piston | pin or crankpin bearings | worn or | 8 | Inspect |

| vafves, | Clean | or replace | as required |

|

| |||||||||||||||||

| scored |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Install | valve kit |

|

|

|

|

|

|

|

|

| ||||

11,Defecgve |

| ball | bearings | on crankshaft | or motor | shaft | 9, | Repair | or replace | as required |

|

|

|

|

|

| ||||||||||||||

12,Leaking | check | valve | or check valve | seer | blown | out | 10 | Inspect |

| ell | Repair or | replace | as | required |

|

|

| |||||||||||||

13,,Ambient | temperature | too | low |

|

|

|

|

| 11. Inspec¿ | bearings | and repla_ce crankshaft | assembly | if | |||||||||||||||||

14,Bad | meter |

|

|

|

|

|

|

|

|

|

|

|

| required |

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| f2 | Replace | cheek valve |

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 13 | Relocate | unit | to warmer | environment |

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Install | crankcase | heater | kit |

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Convert |

| to | synthetic | lubricant |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 14.Replace |

|

|

|

|

|

|

|

|

|

|

|

| ||

Motor | will not | start | 1 | Improper | tine voltage |

|

|

|

|

| 1 | Check |

| fine vottage | and | upgrade | lines | as | required | Contact | |||||||

|

|

| 2 | Wiring | or electric | service | panel | toosmatt |

| eteclrician |

|

|

|

|

|

|

|

|

|

| |||||||

|

|

| 3 | Poor | contact | on | motor | terminals or starter connections | 2 | install | properly | sized | wire or service | box | Contact | electrician | |||||||||||

|

|

| 4 | Improper | starter | overload | heaters |

|

| 3 | Ensure | good contact | on | motor terminals | or starter |

| |||||||||||

|

|

| 5 | Bad motor |

|

|

|

|

|

|

|

|

| connections |

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4 | tnsla]t | proper | starter | overload | heaters | Contact electrician | |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5, | Reptace |

|

|

|

|

|

|

|

|

|

| ||

Oit in | discharge | air (oil | 1 | Lubricant | viseosily toolow |

|

|

| t | Drain | existing | tubricanl | and | refitl | with | proper | lubricant | ||||||||||

pumping) |

| 2 | Detergent | type lubricant |

| being | used |

| 2 | Drain | existing | lubricant | and | refilI | with | proper | lubricant | ||||||||||

|

|

| 3 | Piston | rings | damaged or worn | (broken, | rough or scratched) | 3 | Install | ring kil, |

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

| Excessive | end g_p or side clearance |

| 4 | Adjust |

| piston rings |

|

|

|

|

|

|

|

| |||||||||

|

|

| 4, | Piston | rings | not | seated, |

| are stuck | In grooves or end gaps not | 5 | Repair |

| or replace | as required |

|

|

|

|

|

| ||||||

|

|

|

| staggered, |

|

|

|

|

|

|

|

| 6 | Deglazo | cylinder | with 180 grit ftex_hone |

|

|

| ||||||||

|

|

| g, | Cylinder(s) | or piston(s) | scratched, | worn | or scored | 7 | Drale | recelver tank with manual | dratnvalve |

|

| |||||||||||||

|

|

| 6, | Worn | cylinder | finish |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

| 7. | Excessive | condensate | fn receiver | tank, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

Oil leakinc 1from shaft seal

Safety/relief valve "pops"

1.Crankshaft seat worn or crankshaft scored,

1.Clogged or d_rty Inletandlordlschargeltneftlter

2,, Compressor valves leaky, broken, carbonized or loose 3, Defective safety/refief valve

1, Replace seal or crankshaft assembly,

1.Clean or reptace,

2.Inspect valves. Clean or repface as required Install valve ktt

3 Replace