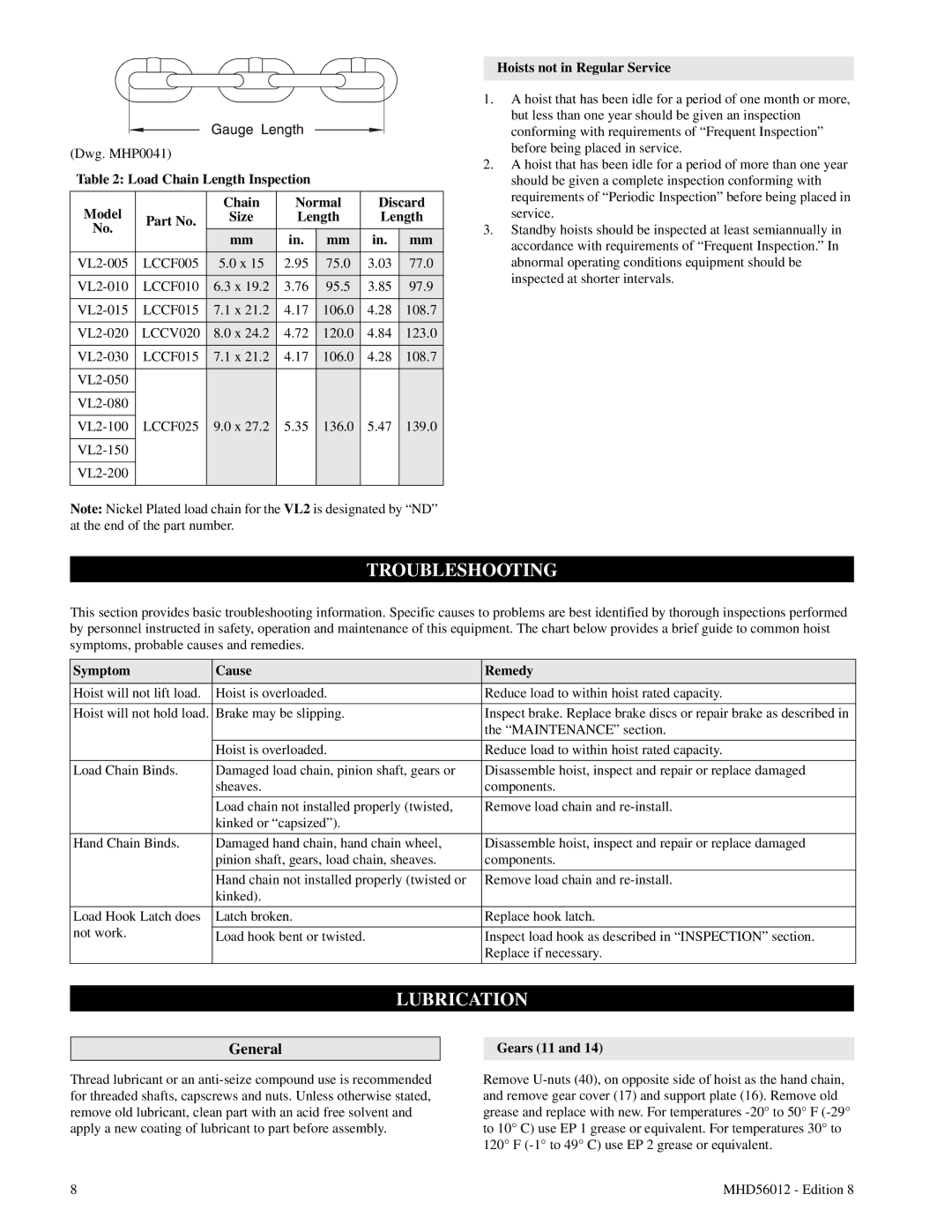

(Dwg. MHP0041)

Table 2: Load Chain Length Inspection

Model |

| Chain | Normal | Discard | ||

Part No. | Size | Length | Length | |||

No. |

|

|

|

|

| |

| mm | in. | mm | in. | mm | |

|

| |||||

LCCF005 | 5.0 x 15 | 2.95 | 75.0 | 3.03 | 77.0 | |

LCCF010 | 6.3 x 19.2 | 3.76 | 95.5 | 3.85 | 97.9 | |

LCCF015 | 7.1 x 21.2 | 4.17 | 106.0 | 4.28 | 108.7 | |

LCCV020 | 8.0 x 24.2 | 4.72 | 120.0 | 4.84 | 123.0 | |

LCCF015 | 7.1 x 21.2 | 4.17 | 106.0 | 4.28 | 108.7 | |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

LCCF025 | 9.0 x 27.2 | 5.35 | 136.0 | 5.47 | 139.0 | |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

Note: Nickel Plated load chain for the VL2 is designated by “ND” at the end of the part number.

Hoists not in Regular Service

1.A hoist that has been idle for a period of one month or more, but less than one year should be given an inspection conforming with requirements of “Frequent Inspection” before being placed in service.

2.A hoist that has been idle for a period of more than one year should be given a complete inspection conforming with requirements of “Periodic Inspection” before being placed in service.

3.Standby hoists should be inspected at least semiannually in accordance with requirements of “Frequent Inspection.” In abnormal operating conditions equipment should be inspected at shorter intervals.

TROUBLESHOOTING

This section provides basic troubleshooting information. Specific causes to problems are best identified by thorough inspections performed by personnel instructed in safety, operation and maintenance of this equipment. The chart below provides a brief guide to common hoist symptoms, probable causes and remedies.

Symptom | Cause | Remedy | |

|

|

| |

Hoist will not lift load. | Hoist is overloaded. | Reduce load to within hoist rated capacity. | |

|

|

| |

Hoist will not hold load. | Brake may be slipping. | Inspect brake. Replace brake discs or repair brake as described in | |

|

| the “MAINTENANCE” section. | |

|

|

| |

| Hoist is overloaded. | Reduce load to within hoist rated capacity. | |

|

|

| |

Load Chain Binds. | Damaged load chain, pinion shaft, gears or | Disassemble hoist, inspect and repair or replace damaged | |

| sheaves. | components. | |

|

|

| |

| Load chain not installed properly (twisted, | Remove load chain and | |

| kinked or “capsized”). |

| |

|

|

| |

Hand Chain Binds. | Damaged hand chain, hand chain wheel, | Disassemble hoist, inspect and repair or replace damaged | |

| pinion shaft, gears, load chain, sheaves. | components. | |

|

|

| |

| Hand chain not installed properly (twisted or | Remove load chain and | |

| kinked). |

| |

|

|

| |

Load Hook Latch does | Latch broken. | Replace hook latch. | |

not work. |

|

| |

Load hook bent or twisted. | Inspect load hook as described in “INSPECTION” section. | ||

| |||

|

| Replace if necessary. | |

|

|

|

LUBRICATION

General

Thread lubricant or an

8

Gears (11 and 14)

Remove

MHD56012 - Edition 8