DC-1200CK specifications

The Jet Tools DC-1200CK is a highly efficient and powerful dust collection system designed for professionals in woodworking and metalworking industries. It provides a clean and safe working environment by effectively capturing dust and debris generated during operations. This dust collector features a robust 1.5 horsepower motor that ensures optimal airflow and suction power, making it an ideal choice for both small workshops and larger industrial setups.One of the standout features of the DC-1200CK is its dual bag system. It comes equipped with a 30-micron filter bag that captures larger particles and a lower collection bag that allows easy disposal of dust. The dual bags work in concert to maximize dust collection, ensuring that the air in the workspace remains cleaner and healthier for users.

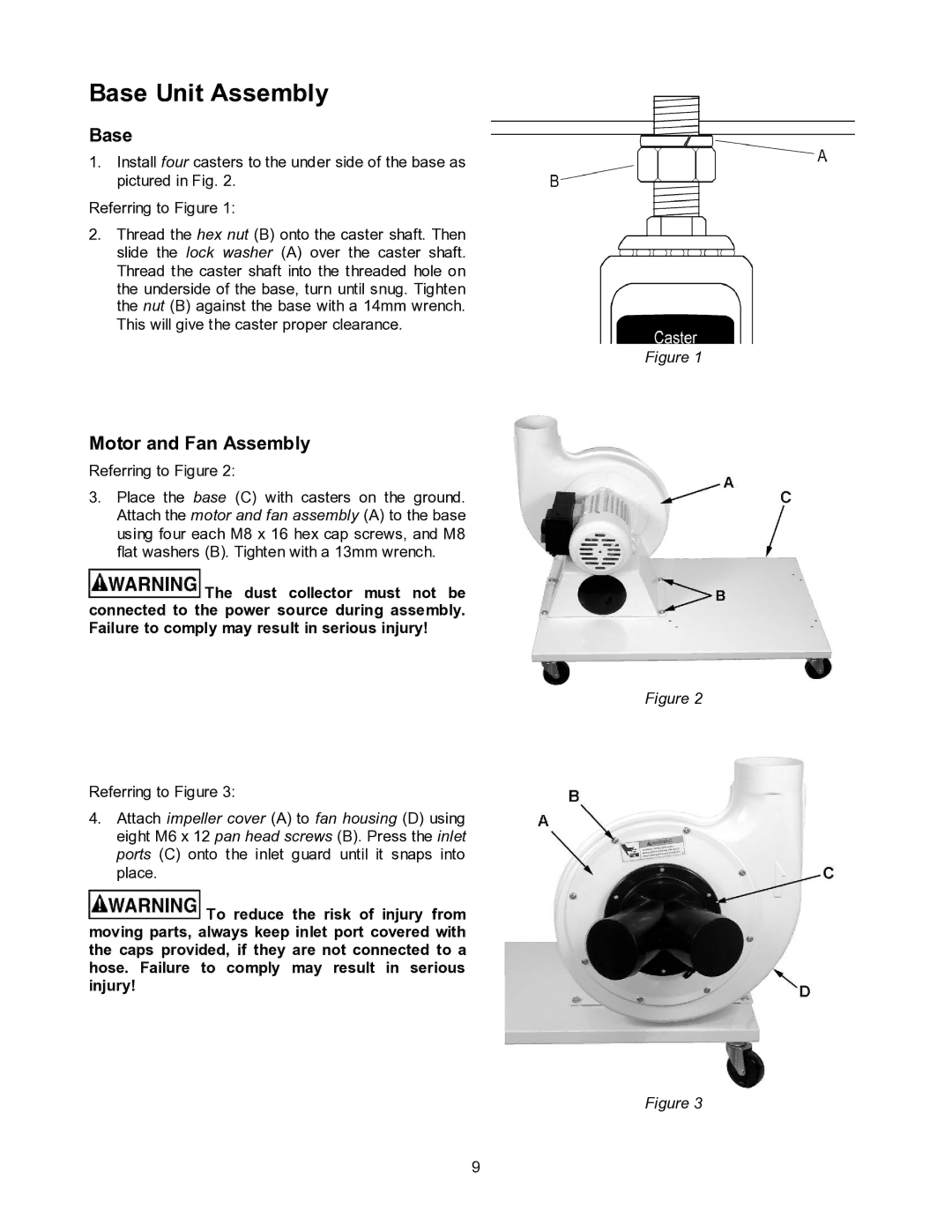

The DC-1200CK also boasts a 12-inch impeller that enhances air movement and efficiency. The impeller is designed to handle a range of materials, from fine sawdust to larger wood chips. This versatility makes it suitable for a variety of dust-producing machines, including table saws, planers, and sanders.

Another significant characteristic of the DC-1200CK is its easy-to-use collection system. The dust collector features a quick-release zipper on the lower bag for hassle-free disposal of collected dust. The top bag also includes a clear window, allowing users to monitor the fill level without removing it. This combination of features enhances usability and ensures that collectors can change out bags quickly and with minimal mess.

The design of the DC-1200CK also emphasizes noise reduction, with a sound level of just 70 decibels, making it quieter than many other options on the market. This is particularly beneficial in work environments where multiple people are working simultaneously.

In terms of mobility, the DC-1200CK comes with sturdy wheels that allow for easy transport within workshops. The integrated handle allows for maneuverability, making it simple to position the collector where it's needed most.

Overall, the Jet Tools DC-1200CK offers a blend of power, efficiency, and convenience, making it an excellent choice for anyone looking to improve their dust collection capabilities while maintaining a clean and safe workspace. Whether for home workshops or professional settings, this dust collector is engineered to meet the demands of serious woodworkers and metalworkers alike.