Adjusting Blade Tension

Blade tension is important to the proper operation of the saw. Proper blade tension is 22,000 to 25,000 Ibs. per square inch as measured on a blade tension gauge.

To set the blade tension without the use of a blade tension gauge:

1.Install the blade between the wheel and insert blade between the bearings on the blade guides.

2.Tension the blade slightly to remove any sag in blade between the blade wheels.

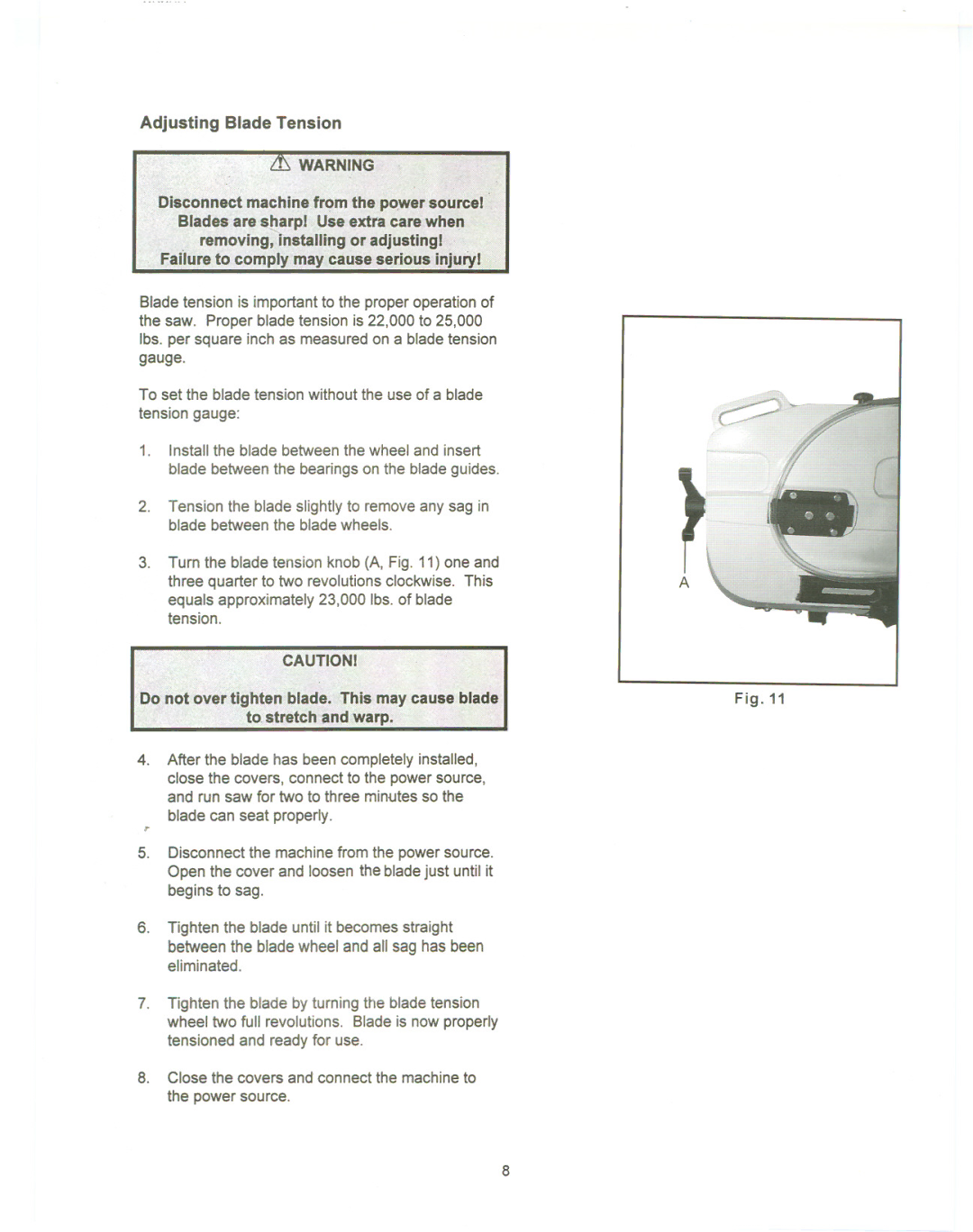

3.Turn the blade tension knob (A, Fig. 11) one and three quarter to two revolutions clockwise. This

equals approximately 23,000 Ibs. of blade tension.

CAUTIONI

A

Fig.11

r

4.After the blade has been completely installed, close the covers. connect to the power source, and run saw for two to three minutes so the

blade can seat properly.

r

5.Disconnect the machine from the power source. Open the cover and loosen the bladejust until it begins to sag.

6.Tighten the blade until it becomes straight between the blade wheel and all sag has been eliminated.

7.Tighten the blade by turning the blade tension wheel two full revolutions. Blade is now properly tensioned and ready for use.

8.Close the covers and connect the machine to the power source.

8