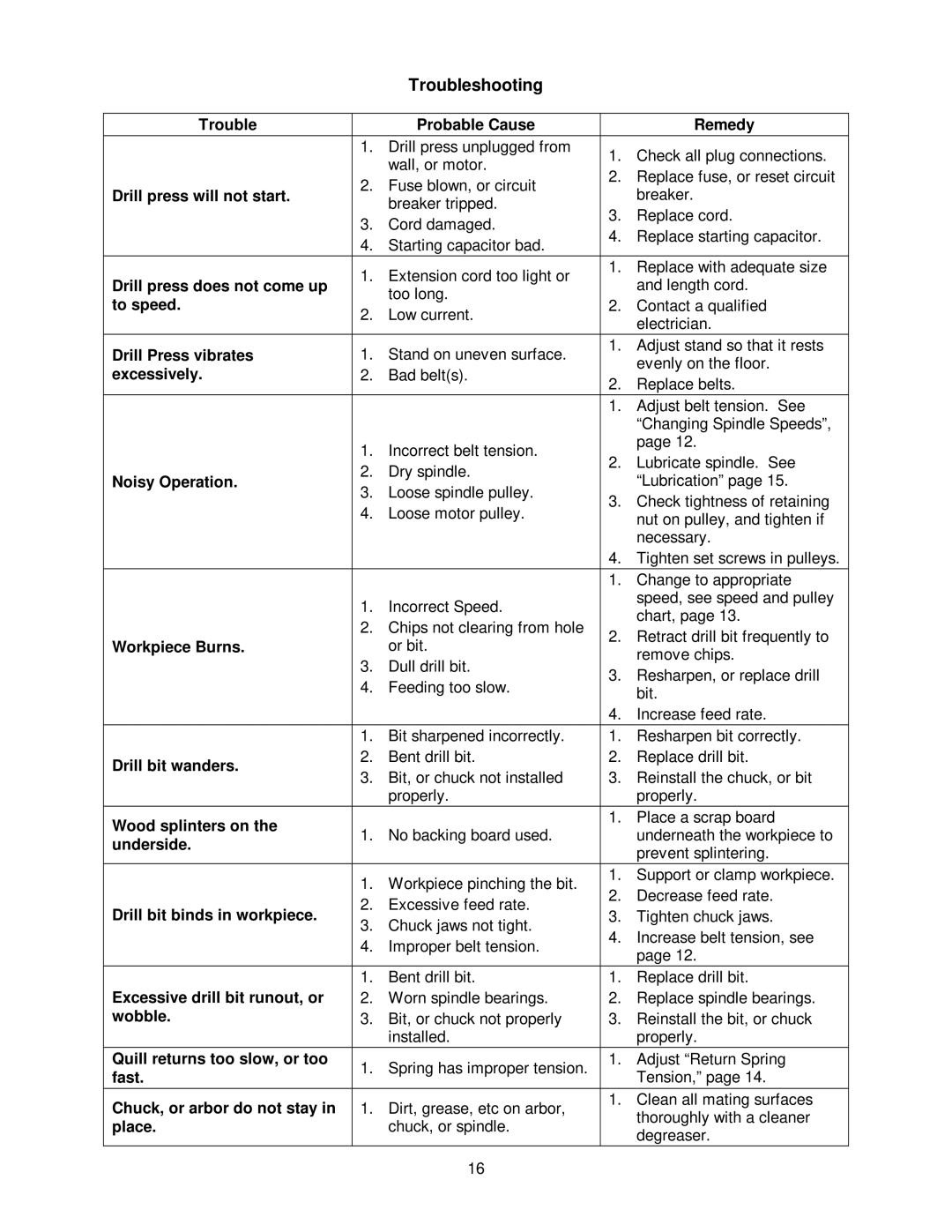

Troubleshooting

Trouble |

| Probable Cause |

| Remedy | |

|

|

|

|

| |

| 1. | Drill press unplugged from | 1. Check all plug connections. | ||

|

| wall, or motor. | |||

|

| 2. Replace fuse, or reset circuit | |||

| 2. | Fuse blown, or circuit | |||

Drill press will not start. |

| breaker. | |||

| breaker tripped. |

| |||

|

| 3. | Replace cord. | ||

| 3. | Cord damaged. | |||

| 4. | Replace starting capacitor. | |||

| 4. | Starting capacitor bad. | |||

|

|

| |||

| 1. | Extension cord too light or | 1. Replace with adequate size | ||

Drill press does not come up |

| and length cord. | |||

| too long. |

| |||

to speed. |

| 2. | Contact a qualified | ||

2. | Low current. | ||||

|

| electrician. | |||

|

|

|

| ||

Drill Press vibrates | 1. | Stand on uneven surface. | 1. Adjust stand so that it rests | ||

| evenly on the floor. | ||||

excessively. | 2. | Bad belt(s). |

| ||

2. | Replace belts. | ||||

|

|

| |||

|

|

| 1. Adjust belt tension. See | ||

|

|

|

| “Changing Spindle Speeds”, | |

| 1. | Incorrect belt tension. |

| page 12. | |

| 2. | Lubricate spindle. See | |||

| 2. | Dry spindle. | |||

Noisy Operation. |

| “Lubrication” page 15. | |||

3. | Loose spindle pulley. |

| |||

| 3. Check tightness of retaining | ||||

| 4. | Loose motor pulley. | |||

|

| nut on pulley, and tighten if | |||

|

|

|

| ||

|

|

|

| necessary. | |

|

|

| 4. Tighten set screws in pulleys. | ||

|

|

| 1. | Change to appropriate | |

| 1. | Incorrect Speed. |

| speed, see speed and pulley | |

|

| chart, page 13. | |||

| 2. | Chips not clearing from hole |

| ||

| 2. Retract drill bit frequently to | ||||

Workpiece Burns. |

| or bit. | |||

|

| remove chips. | |||

| 3. | Dull drill bit. |

| ||

| 3. Resharpen, or replace drill | ||||

| 4. | Feeding too slow. | |||

|

| bit. | |||

|

|

|

| ||

|

|

| 4. | Increase feed rate. | |

| 1. | Bit sharpened incorrectly. | 1. | Resharpen bit correctly. | |

Drill bit wanders. | 2. | Bent drill bit. | 2. | Replace drill bit. | |

3. | Bit, or chuck not installed | 3. | Reinstall the chuck, or bit | ||

| |||||

|

| properly. |

| properly. | |

Wood splinters on the |

|

| 1. Place a scrap board | ||

1. | No backing board used. |

| underneath the workpiece to | ||

underside. |

| ||||

|

|

| prevent splintering. | ||

|

|

|

| ||

| 1. | Workpiece pinching the bit. | 1. Support or clamp workpiece. | ||

| 2. | Decrease feed rate. | |||

| 2. | Excessive feed rate. | |||

Drill bit binds in workpiece. | 3. | Tighten chuck jaws. | |||

3. | Chuck jaws not tight. | ||||

| 4. Increase belt tension, see | ||||

| 4. | Improper belt tension. | |||

|

| page 12. | |||

|

|

|

| ||

| 1. | Bent drill bit. | 1. | Replace drill bit. | |

Excessive drill bit runout, or | 2. | Worn spindle bearings. | 2. | Replace spindle bearings. | |

wobble. | 3. | Bit, or chuck not properly | 3. | Reinstall the bit, or chuck | |

|

| installed. |

| properly. | |

Quill returns too slow, or too | 1. | Spring has improper tension. | 1. | Adjust “Return Spring | |

fast. |

| Tension,” page 14. | |||

|

|

| |||

|

|

|

| ||

Chuck, or arbor do not stay in | 1. | Dirt, grease, etc on arbor, | 1. Clean all mating surfaces | ||

| thoroughly with a cleaner | ||||

place. |

| chuck, or spindle. |

| ||

|

| degreaser. | |||

|

|

|

| ||

16