11.0Maintenance

![]() Before doing maintenance on the lathe, disconnect it from the electrical supply by pulling out the plug or switching off the main switch. Failure to comply may cause serious injury.

Before doing maintenance on the lathe, disconnect it from the electrical supply by pulling out the plug or switching off the main switch. Failure to comply may cause serious injury.

11.1General procedures

Maintenance on the lathe should be performed at periodic intervals to ensure that the machine is in proper working order, that all fasteners are tight, and all necessary adjustments have been made. Inspection and maintenance should be performed at least twice a year, but more frequently if the lathe receives constant use.

Clean and oil the lathe bed so that headstock, tailstock and tool rest base will slide easily. Clean any rust spots that may develop on the bed with a commercial rust remover.

Use compressed air to blow out the interior of the headstock, in order to keep sawdust and chips from accumulating on belts and sheaves. Also blow off debris that accumulates in the motor fan.

Frequently clean out the morse tapers on both headstock and tailstock. Commercially available taper cleaners may be acquired from tool stores.

Bearings are permanently lubricated and sealed, and do not require further lubrication.

11.2Pulley lubrication

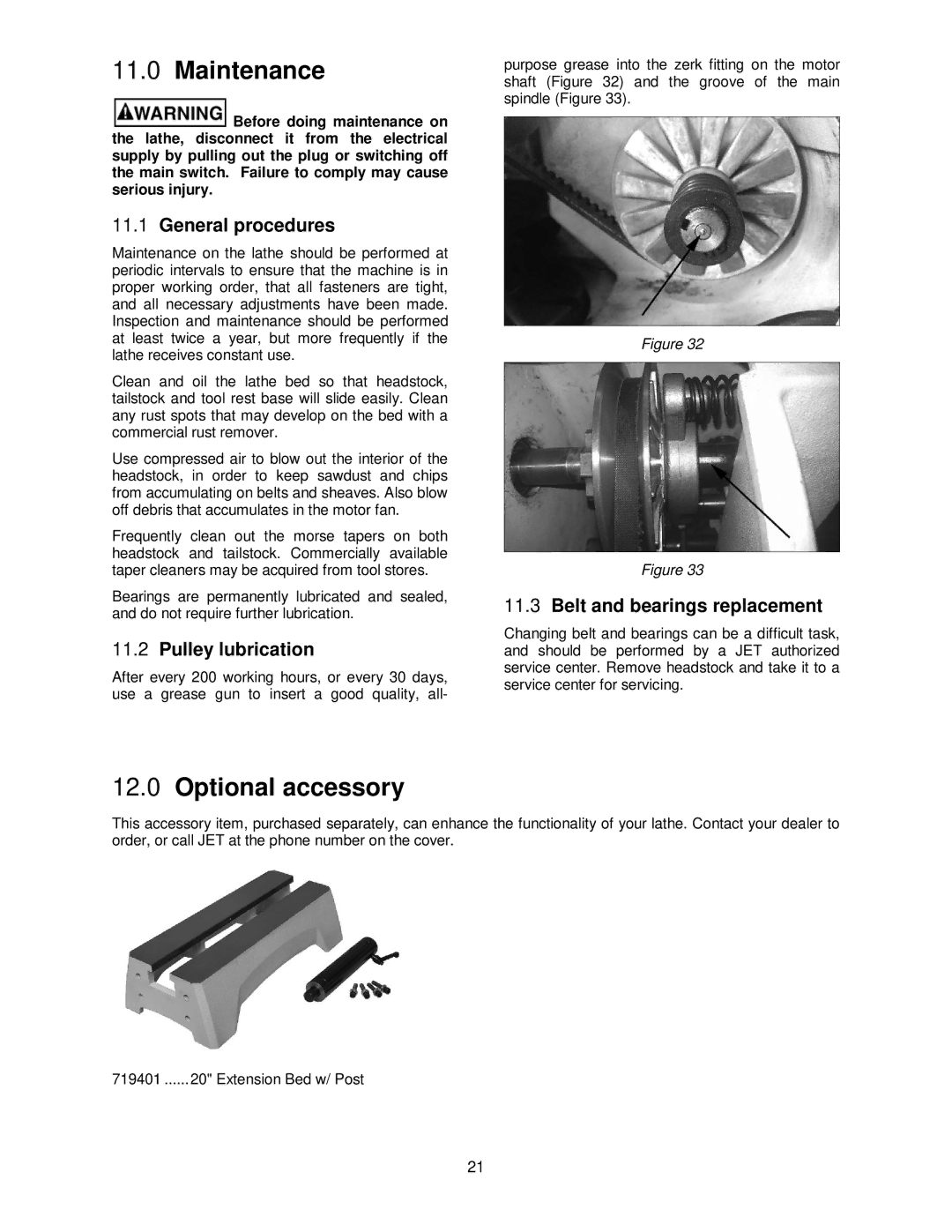

After every 200 working hours, or every 30 days, use a grease gun to insert a good quality, all-

purpose grease into the zerk fitting on the motor shaft (Figure 32) and the groove of the main spindle (Figure 33).

Figure 32

Figure 33

11.3Belt and bearings replacement

Changing belt and bearings can be a difficult task, and should be performed by a JET authorized service center. Remove headstock and take it to a service center for servicing.

12.0Optional accessory

This accessory item, purchased separately, can enhance the functionality of your lathe. Contact your dealer to order, or call JET at the phone number on the cover.

719401 ......20" Extension Bed w/ Post

21