1 888 275 4538 - 611

514 737 9701 - 611

FAX 514 737 2792

The quantity of liquid detergent can be increased (clockwise) or decreased (counter clockwise) by adjusting the screw on the peristaltic pump. The pump works during the fill cycle and rinse cycle.

(Identified above as “Adjustment screw”)

Don't forget to put the panel back on when finished.

RINSE PUMP ADJUSTMENT AND PRIMING

·The rinse pump is standard equipment on all

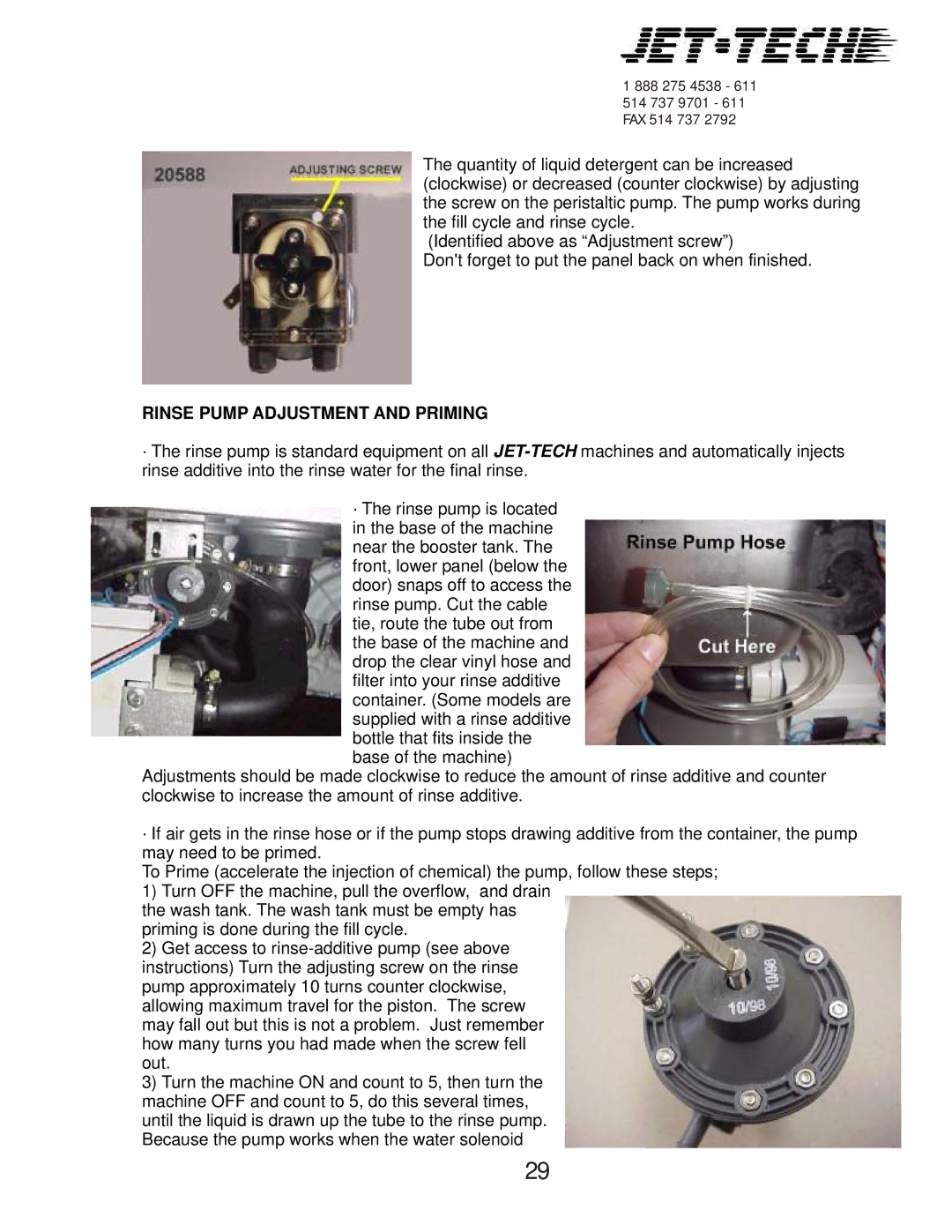

·The rinse pump is located in the base of the machine near the booster tank. The front, lower panel (below the door) snaps off to access the rinse pump. Cut the cable tie, route the tube out from the base of the machine and drop the clear vinyl hose and filter into your rinse additive container. (Some models are supplied with a rinse additive bottle that fits inside the base of the machine)

Adjustments should be made clockwise to reduce the amount of rinse additive and counter clockwise to increase the amount of rinse additive.

·If air gets in the rinse hose or if the pump stops drawing additive from the container, the pump may need to be primed.

To Prime (accelerate the injection of chemical) the pump, follow these steps; 1) Turn OFF the machine, pull the overflow, and drain

the wash tank. The wash tank must be empty has priming is done during the fill cycle.

2) Get access to

3) Turn the machine ON and count to 5, then turn the machine OFF and count to 5, do this several times, until the liquid is drawn up the tube to the rinse pump. Because the pump works when the water solenoid

29