PROTECTION AGAINST RODENTS

When used in locations vulnerable to rodent attack, all plastic pipes and fittings should be adequately protected within sealed ducts.

Speedfit products along with other materials such as electrical cables may be damaged if rodents are present. If vermin infestation is suspected then a rodent exterminator should take appropriate action.

BIOLOGICAL

No taste, colour, odour or toxicity is imparted to water by Speedfit components, nor do they promote microbiological growth.

In accordance with BS7291: Part 1 Clause 6.7, the opacity of both pipes and fittings allows insufficient light to pass for the growth of algae

Tests within the Water Regulations Advisory Scheme, have approved Speedfit pipe and fittings to BS 6920 for water quality.

SYSTEM TESTING

On completion of the plumbing and heating system it is essential that system checking and a hydraulic wet test takes place. Connections to boilers, radiators and sanitary ware should first be capped or plugged.

Testing should be carried out at 2 bar for 10 minutes followed by 10 bar for 10 minutes.

This testing combined with other relevant checks, should reveal most system problems. Any components within the system not designed to take these pressures should be disconnected.

Before carrying out a pressure test ensure all Speedfit pipe and fittings are installed correctly. Speedfit Barrier Pipe is printed with insertion marks to help ensure full insertion has been achieved.

Remember pressure testing is NOT a substitute for making sure fittings are clean and free of any grit, dirt or swarf and the pipe is correctly inserted (see Making a Good Connection, on page 06.

SYSTEM COMMISSIONING AND FLUSHING

With existing systems, flushing prior to the use of Speedfit is essential to remove any harmful contamination or chemical residues from elsewhere in the system.

For the installation of central heating systems flushing procedures must be in line with BS7593 code of practice for treatment of water in domestic hot water heating systems.

Flux residues used in the soldering of capillary fittings are very corrosive. Dirt and grit, which can enter the system when Speedfit pipe is being pushed through underfloor or across a roof space, must be removed.

21

During the commissioning of a heating system, all air must be removed from the system before the boiler is allowed to fire. This will ensure pockets of air do not cause localized overheating within the system as this could have a detrimental affect on the pipework and boiler.

For further advice on chemical flushing agents and inhibitor treatments, the following manufacturers should be contacted: Fernox Manufacturing Ltd., 01799 550811 or Sentinel Betz Dearborn Ltd., 0151 420 9595.

TECHNICAL ADVISORY SERVICE

The JG Speedfit Technical Advisory Service is available to assist and advise on all aspects of using the Speedfit system. The service is available between 8.00am and 4.30pm, Monday to Friday on Telephone No. 01895 425333 and Fax No. 01895 425350. Products within this Product Guide are designed for use within UK plumbing and heating installations or in other countries where similar installation requirements apply. For information on products suitable for use in other countries please consult our Technical Advisory Service.

We take pride in the quality of our products and all complaints are investigated thoroughly. If you have a problem with a Speedfit Product please return both fitting and pipe to us for investigation. We will need at least 50mm of pipe to ensure an accurate analysis. If there is a suspicion that the pipe is faulty, please provide marking details from the pipe.

COMMON PROBLEMS AND IDENTIFICATION

Problem: Burst or melted pipe.

Pipe will be distorted showing either a ‘Parrot beak’ look or a long opening with the edges of the pipe melted in a wave shape.

Identification: A ‘Parrot beak’ will have been formed by the pipe bursting due to the water freezing. If the Pipe has a melted appearance it will have been subject to a temperature in excess of 128 degrees Celsius. This will have been caused by direct contact with a heat source such as a blowtorch or flue pipe or by water or steam within the system rising above safety levels.

Problem: A fitting or part of a fitting dissolved - the fitting may have blown off the pipe and may have missing component parts.

Identification: The fitting will have failed because of a chemical attack. The most common attack is from acid based solder flux running down into the fitting during soldering of a nearby copper fitting or flux coming into contact with the fitting in some other way.

Problem: Weep from fitting.

Identification : The pipe has not been fully inserted up to the pipe stop or one or both of the ‘O’ rings have been damaged by burrs or sharp edges on the end of pipe. See ‘What Not to Do’ on page 06.

Problem: The fitting has blown off the pipe. Fitting is missing the collet, the pipe insert is still inside the fitting after the pipe has come out.

Identification: If this happens on first fix, the most likely reason is that the pipe has not been fully inserted into the fitting, up to the pipe stop, and the system has not been pressure tested.

If the collet (gripping device) is missing everything will blow out. If the collet is there and the pipe support is still inside the connector but the pipe has still blown out, this means that full insertion had not been accomplished.

UNDERFLOOR HEATING

The Speedfit Underfloor Heating System has been designed to be as quick and easy as possible to install with component parts manufactured to UK and European standards.

Underfloor heating provides the most comfortable even warmth of any heating system. It is economical to run and virtually maintenance free. The principle has been with us since Roman times but is still the system of choice in some European countries, accounting for 70% of installations.

The Speedfit System has water being pumped from a boiler to a pump pack, where it is mixed to approximately 50ºC then distributed via a manifold to heating circuits made using Speedfit Barrier Pipe. The pipe is laid in concrete or suspended just below the surface of the floor.

In concrete floors, the pipe is laid on insulation and then covered with a screed on which can be laid almost any type of floor covering.

For timber floors, spreader plates are laid between the joists and the floor decking or on the underside of the floor. Speedfit Pipe is pushed into the grooves on the plates.

The floor area is typically warmed to between 25ºC and 28ºC, providing an even distribution of heat at only slightly higher than room temperature. The system is controlled by one or more thermostats which signal the Pump Pack when heat is required.

UNDERFLOOR HEATING SYSTEM

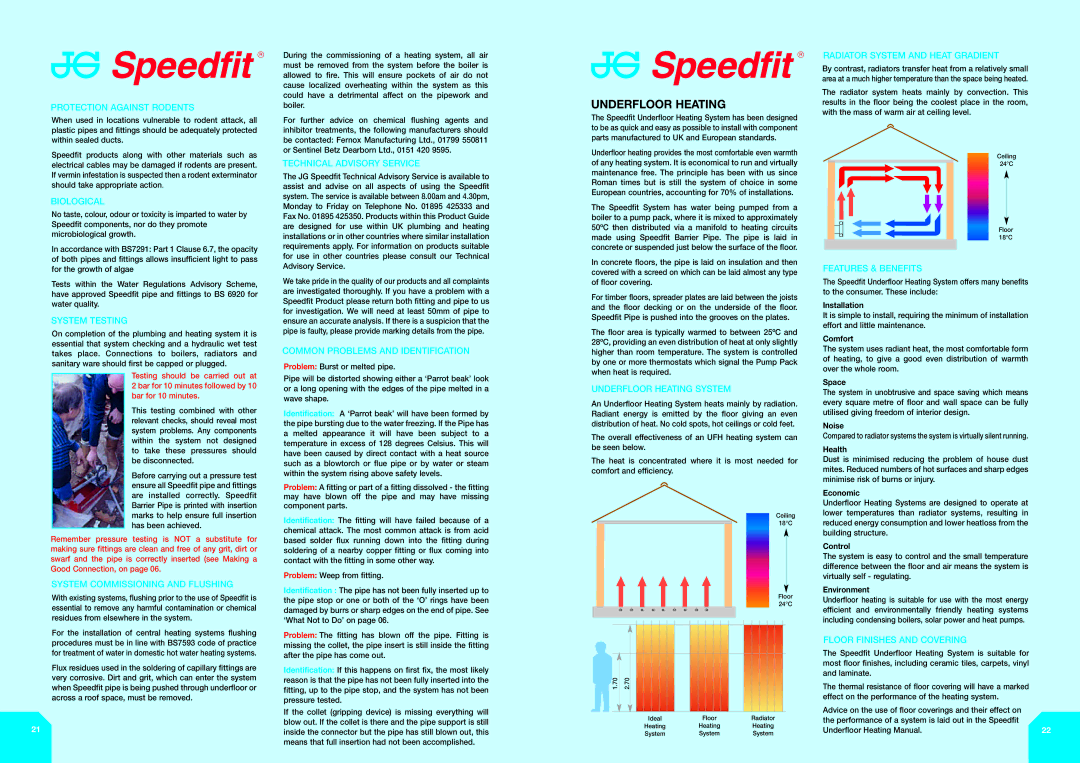

An Underfloor Heating System heats mainly by radiation. Radiant energy is emitted by the floor giving an even distribution of heat. No cold spots, hot ceilings or cold feet.

The overall effectiveness of an UFH heating system can be seen below.

The heat is concentrated where it is most needed for comfort and efficiency.

Ceiling

18°C

Floor 24°C

Ideal | Floor | Radiator |

Heating | Heating | Heating |

System | System | System |

RADIATOR SYSTEM AND HEAT GRADIENT

By contrast, radiators transfer heat from a relatively small area at a much higher temperature than the space being heated.

The radiator system heats mainly by convection. This results in the floor being the coolest place in the room, with the mass of warm air at ceiling level.

Ceiling

24°C

Floor 18°C

FEATURES & BENEFITS

The Speedfit Underfloor Heating System offers many benefits to the consumer. These include:

Installation

It is simple to install, requiring the minimum of installation effort and little maintenance.

Comfort

The system uses radiant heat, the most comfortable form of heating, to give a good even distribution of warmth over the whole room.

Space

The system in unobtrusive and space saving which means every square metre of floor and wall space can be fully utilised giving freedom of interior design.

Noise

Compared to radiator systems the system is virtually silent running.

Health

Dust is minimised reducing the problem of house dust mites. Reduced numbers of hot surfaces and sharp edges minimise risk of burns or injury.

Economic

Underfloor Heating Systems are designed to operate at lower temperatures than radiator systems, resulting in reduced energy consumption and lower heatloss from the building structure.

Control

The system is easy to control and the small temperature difference between the floor and air means the system is virtually self - regulating.

Environment

Underfloor heating is suitable for use with the most energy efficient and environmentally friendly heating systems including condensing boilers, solar power and heat pumps.

FLOOR FINISHES AND COVERING

The Speedfit Underfloor Heating System is suitable for most floor finishes, including ceramic tiles, carpets, vinyl and laminate.

The thermal resistance of floor covering will have a marked effect on the performance of the heating system.

Advice on the use of floor coverings and their effect on | |

the performance of a system is laid out in the Speedfit | |

Underfloor Heating Manual. | 22 |