BS7291, KM39767 specifications

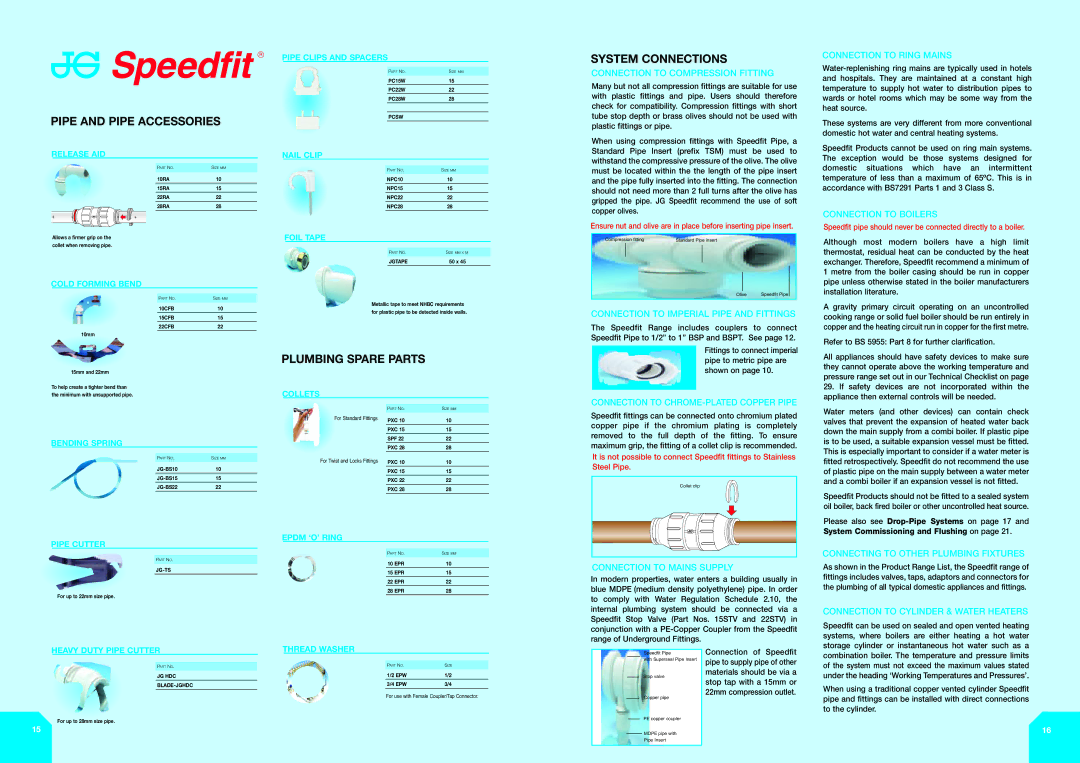

John Mills BS7291, KM39767 represents a high standard of engineering and manufacturing excellence in the field of industrial components. This specific designation is associated with a range of products that are integral in various applications across multiple sectors, including manufacturing, construction, and infrastructure. The BS7291 standard is part of the British Standards for thermoplastic pipes and fittings, offering specifications that ensure safety, efficiency, and environmental sustainability.One of the main features of John Mills BS7291 is its adaptability. The products meet the requirements for various applications, particularly in the transportation of fluids, which is crucial in plumbing and drainage systems. This versatility makes it an ideal choice for both commercial and industrial projects.

John Mills also incorporates advanced technologies in the manufacturing process. The use of high-density polyethylene (HDPE) and other durable materials ensures that the equipment is not only lightweight and easy to install but also resilient against pressure and temperature fluctuations. Additionally, the products often include innovative sealing mechanisms that enhance leak resistance, showcasing a commitment to quality and reliability.

The characteristics of John Mills BS7291, KM39767 include excellent chemical resistance, making it suitable for use with a variety of fluids, including hazardous substances. The robust construction of these components allows them to withstand harsh environmental conditions, further extending their lifespan. Furthermore, the smooth inner surface of the pipes reduces friction and allows for the efficient flow of liquids, resulting in energy savings and reduced costs for users.

Another important aspect of this range is its compliance with environmental regulations, which is becoming increasingly critical in today’s industry landscape. John Mills products are designed with sustainability in mind, helping to reduce ecological footprints and ensure responsible resource management.

In summary, John Mills BS7291, KM39767 stands out in the industry for its focus on quality, advanced materials, and adherence to stringent standards. These features contribute to their reliability and efficiency in a wide array of applications, making them a preferred choice for professionals in the field.