AL6B SERIES, AC6B, 16 SEER - CZF specifications

The Johnson Controls AC6B, AL6B Series air conditioning units are designed to deliver efficient cooling solutions for residential and commercial applications. Known for their advanced technology and superior performance, these units comply with the latest standards in energy efficiency, boasting a 16 SEER (Seasonal Energy Efficiency Ratio) rating. This high rating indicates that these air conditioning systems consume less power while delivering optimum cooling, leading to significant cost savings on energy bills.One of the standout features of the AC6B, AL6B Series is their variable-speed compressor technology. This allows the unit to adjust its cooling output in response to the specific demands of the environment, ensuring consistent temperatures while minimizing energy consumption. The variable-speed operation helps reduce wear and tear on the system, increasing longevity and reliability.

Another key characteristic of these units is their eco-friendly refrigerant, which contributes to lower environmental impact. The AC6B, AL6B Series utilize advanced heat exchanger designs that enhance heat transfer efficiency, further optimizing cooling performance while reducing energy usage.

Designed with user comfort in mind, these systems come equipped with advanced dehumidification capabilities, effectively managing indoor humidity levels. This ensures a more comfortable living or working environment, especially in humid climates.

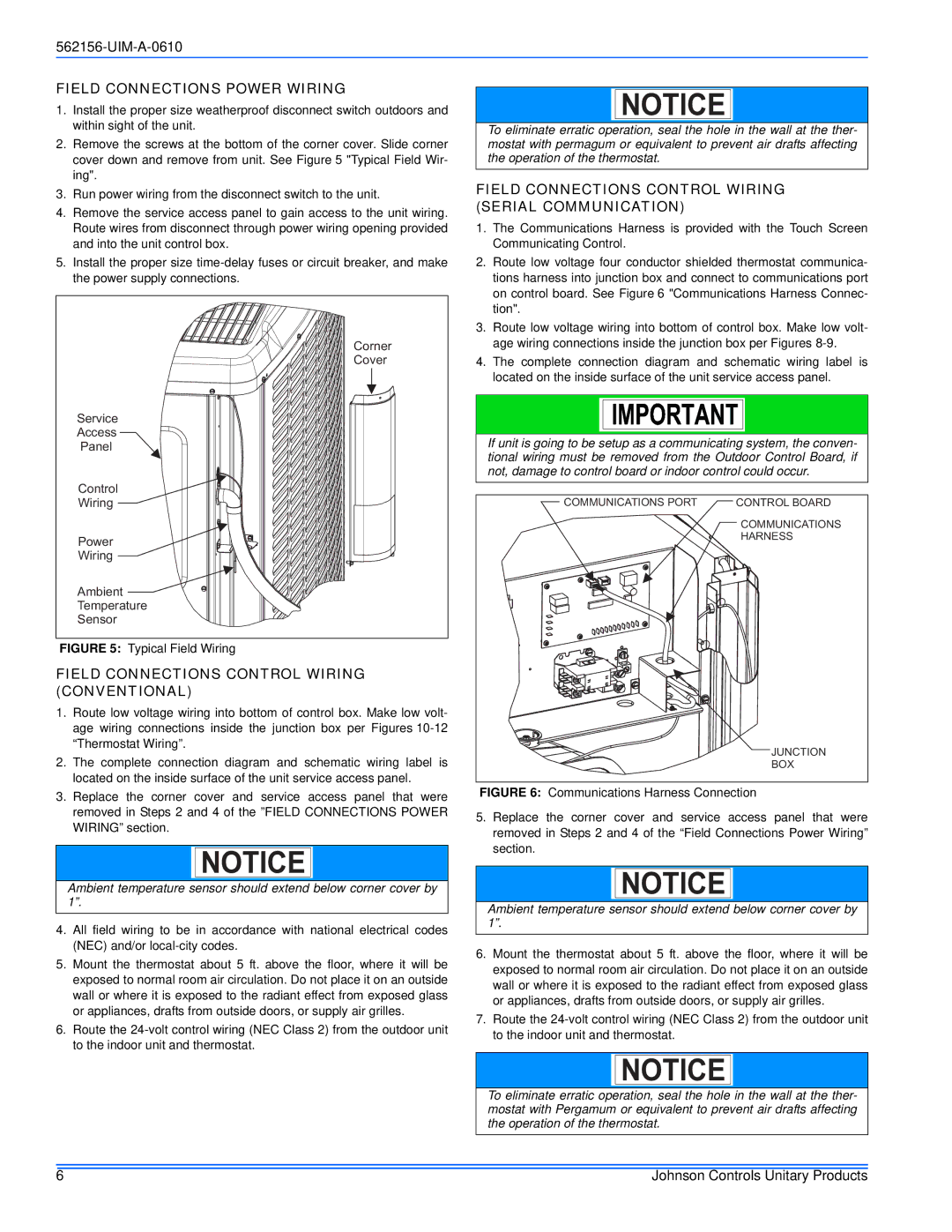

In addition to performance, installation and maintenance are simplified with the AC6B, AL6B Series. The units are engineered for ease of installation, featuring lightweight components that reduce labor costs. Maintenance is also straightforward, with accessible service panels and clear maintenance guidelines, offering further convenience for homeowners and facility managers alike.

The aesthetic design of the AC6B, AL6B Series blends seamlessly into various architectural styles, making them an attractive choice for both new constructions and retrofits. The robust construction quality ensures durability, suitable for varying weather conditions.

Overall, the Johnson Controls AC6B, AL6B Series air conditioning units present a comprehensive solution for those seeking energy-efficient, reliable, and user-friendly cooling systems. With their multitude of features and advanced technology, they stand as a robust option for enhancing indoor comfort while minimizing environmental impact.