IFC-640 specifications

Johnson Controls IFC-640 is a pioneering fire alarm control panel that integrates advanced technologies to ensure safety and protection in commercial and industrial applications. As a part of the Johnson Controls extensive portfolio, the IFC-640 offers detailed monitoring and control capabilities, making it a reliable choice for fire management systems.One of the standout features of the IFC-640 is its robust addressable technology. This system allows for precise identification of each alarm device, enabling quick location tracking during emergencies. The incorporation of intelligent algorithms enhances the panel's ability to distinguish between actual fire events and false alarms, thereby improving overall response efficiency.

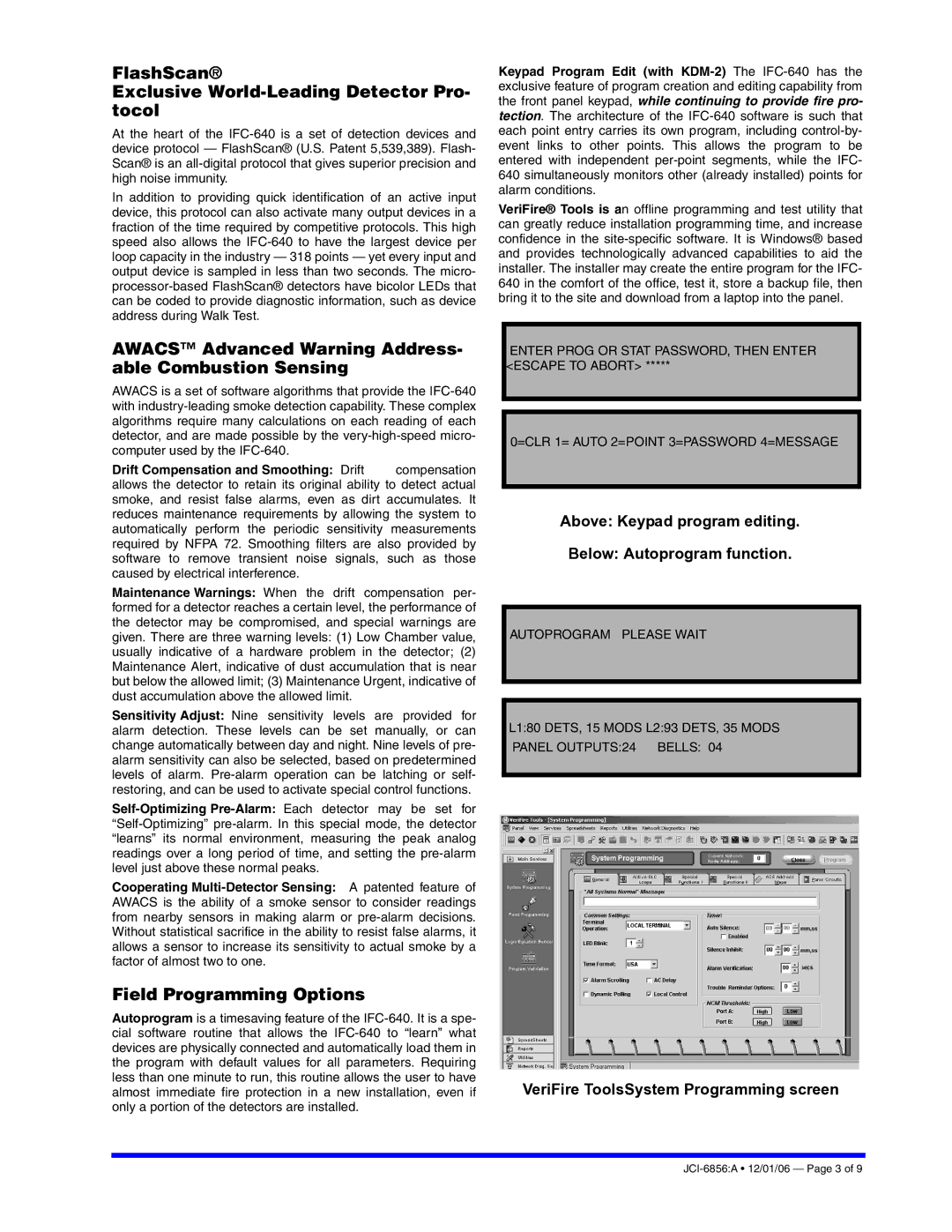

Another significant characteristic of the IFC-640 is its user-friendly interface. The panel is equipped with a color LCD display that provides real-time status updates on the system’s operation. This visual clarity ensures that operators can quickly comprehend alerts and other vital information. The intuitive navigation allows users to manage settings and view system events with ease, minimizing the training required for new personnel.

The IFC-640 also boasts a modular architecture, allowing for seamless scalability. This feature enables the system to adapt to varying building sizes and complexities without needing extensive upgrades. Integration capabilities with third-party systems facilitate compatibility with existing infrastructure, making the IFC-640 a versatile choice for a diverse range of environments.

Network capabilities are enhanced with the panel's ability to connect monitoring stations and multiple units in a single system. This networking function allows for centralized management of multiple installations, improving overall safety management across large campuses or facilities.

Safety and reliability are further reinforced by the IFC-640’s built-in redundancy features. This ensures continuous operation even in the event of a power outage, providing peace of mind to facility managers and stakeholders.

In summary, the Johnson Controls IFC-640 fire alarm control panel exemplifies cutting-edge engineering with its addressable technology, user-friendly interface, modular design, and robust networking capabilities. With these features, it stands as an effective solution for safeguarding lives and property against fire hazards.