TG8S*MP, GG8S*MP, TGLS*MP, GGLS*MP specifications

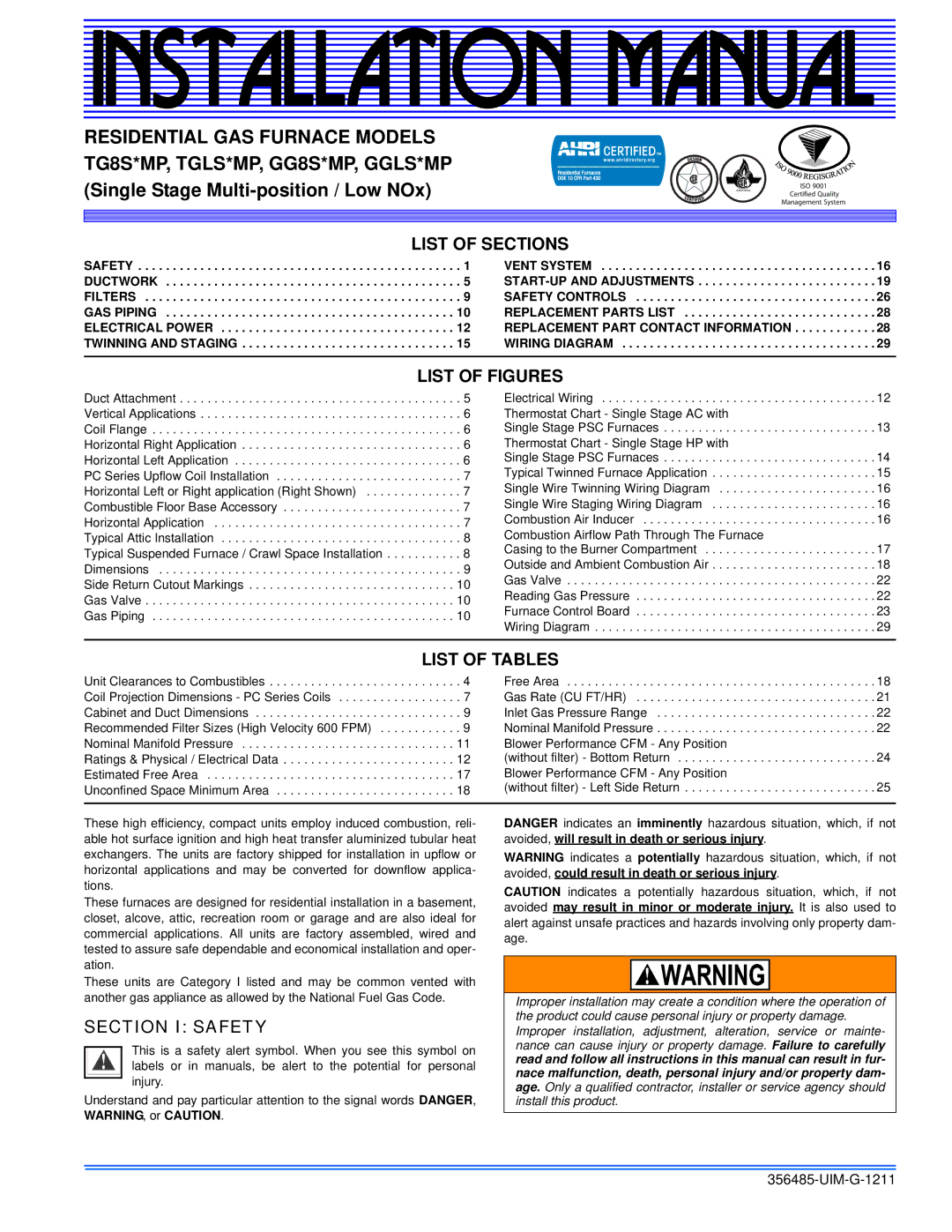

Johnson Controls is a leader in the development of innovative building management solutions, and its product line encompassing the GGLS*MP, TGLS*MP, TG8S*MP, and GG8S*MP series exemplifies this commitment to excellence. These devices are designed to optimize energy efficiency, enhance occupant comfort, and ensure seamless integration into commercial building infrastructures.The GGLS*MP series focuses on the integration of advanced sensors and controllers that facilitate effective lighting and HVAC management. With built-in capabilities for occupancy sensing and daylight harvesting, these devices can automatically adjust settings based on real-time conditions. Their energy-efficient operation not only contributes to lower utility costs but also supports sustainability goals, making them ideal for modern green buildings.

In contrast, the TGLS*MP series emphasizes the importance of temperature regulation and comfort in residential or smaller commercial settings. These controllers utilize advanced algorithms to maintain optimal indoor climates, adjusting heating and cooling outputs in response to ambient conditions. The intuitive user interface makes it easy for users to customize their settings, providing enhanced comfort without sacrificing energy efficiency.

The TG8S*MP series is particularly renowned for its robust communication features. These devices support multiple communication protocols, allowing them to integrate smoothly with existing building management systems. This versatility ensures that customers can leverage their current infrastructure while benefiting from new technology. Additionally, the TG8S*MP includes remote monitoring capabilities, enabling facility managers to track performance metrics and troubleshoot issues from anywhere.

Lastly, the GG8S*MP series brings together security and control features, ensuring that buildings are not only energy-efficient but also secure. With capabilities for access control and monitoring, these devices provide a comprehensive solution for managing facility safety. Their integration with lighting and HVAC systems further enhances overall efficiency, creating a comfortable and secure environment for all occupants.

In summary, Johnson Controls’ GGLS*MP, TGLS*MP, TG8S*MP, and GG8S*MP series presents cutting-edge technologies designed for energy efficiency, ease of use, and versatility. By focusing on comprehensive building management, these products provide optimal performance that aligns with sustainability objectives while enhancing comfort and security. Whether in commercial or residential settings, Johnson Controls continues to lead the way in the intelligent building sector.