4/29/03

4:Insert the mounting stud (B) into the guide casting (A). Keep the stud flush with the front of the casting. Keeping the mounting stud flat area on the bottom, tighten securely the set screw (C) on the bottom of the casting.

5:Insert this stud and guide assembly into the 7/16” hole in the guidepost. Make sure upper roller guide is plumb with the guidepost. Lightly tighten set screw you installed in the guidepost.

Lower Guide Installation:

6:Remove lower blade guide. Replace this guide with the high speed guide containing the

mounting bracket with slotted hole, reusing existing nuts / bolts.

Position assembly upward along the slotted bracket, so that the guide body casting has enough clearance to allow the work table to be tilted for angle cutting. Tighten the socket head cap screw or nut.

Note: Make certain that if a socket head cap screw is used, it does not bottom out into the main saw casting item 1. Shorten the cap screw if necessary

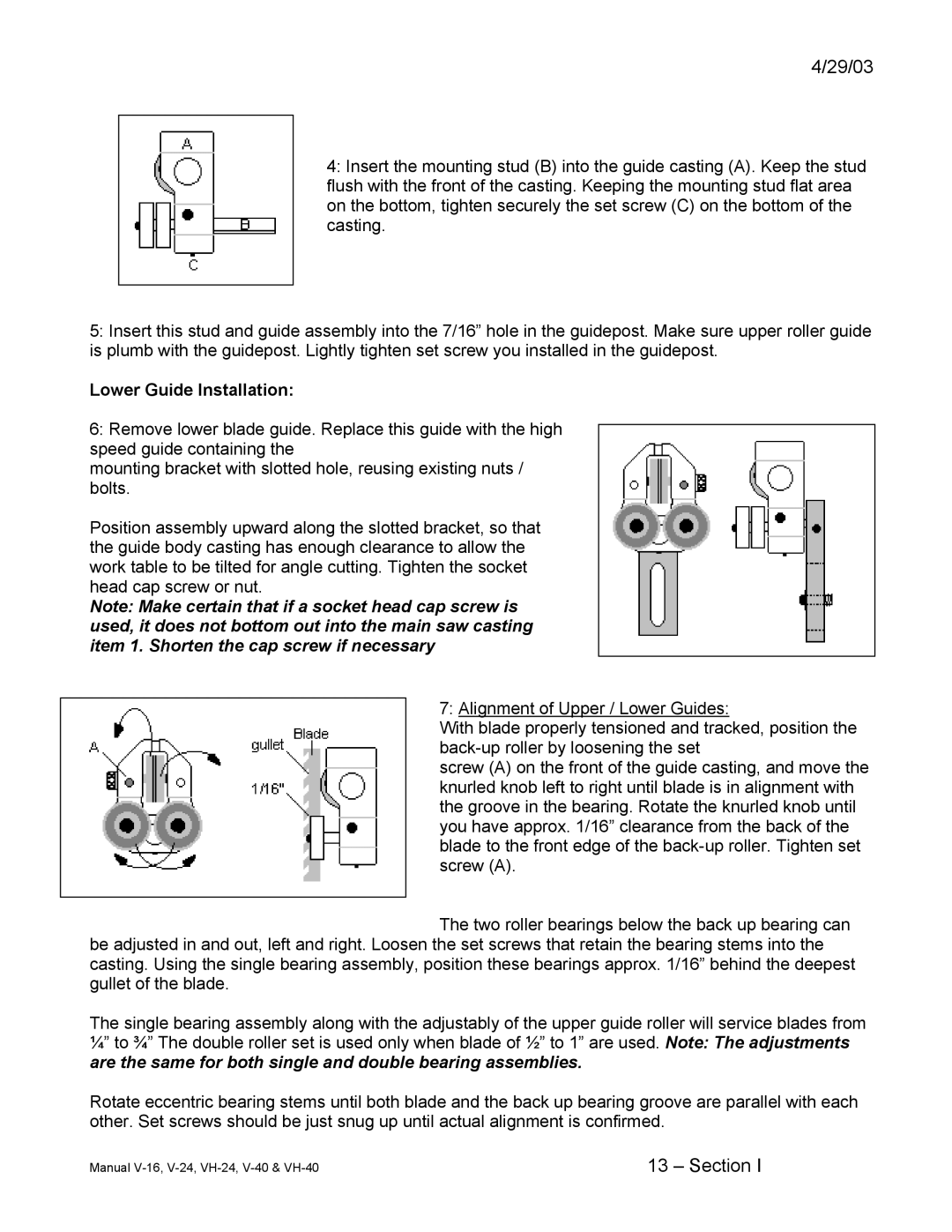

7:Alignment of Upper / Lower Guides:

With blade properly tensioned and tracked, position the

screw (A) on the front of the guide casting, and move the knurled knob left to right until blade is in alignment with the groove in the bearing. Rotate the knurled knob until you have approx. 1/16” clearance from the back of the blade to the front edge of the

The two roller bearings below the back up bearing can

be adjusted in and out, left and right. Loosen the set screws that retain the bearing stems into the casting. Using the single bearing assembly, position these bearings approx. 1/16” behind the deepest gullet of the blade.

The single bearing assembly along with the adjustably of the upper guide roller will service blades from ¼” to ¾” The double roller set is used only when blade of ½” to 1” are used. Note: The adjustments

are the same for both single and double bearing assemblies.

Rotate eccentric bearing stems until both blade and the back up bearing groove are parallel with each other. Set screws should be just snug up until actual alignment is confirmed.

Manual | 13 – Section I |