Chain Maintenance

Chain maintenance - safety

For personal safety, it is of great importance to use bar and chain combinations of the

Important notes :

•Chain tension

•Sharpening

•Lubrication

•Maintenance

STOP WARNING!

Always disconnect power supply before fitting parts or adjusting the saw.

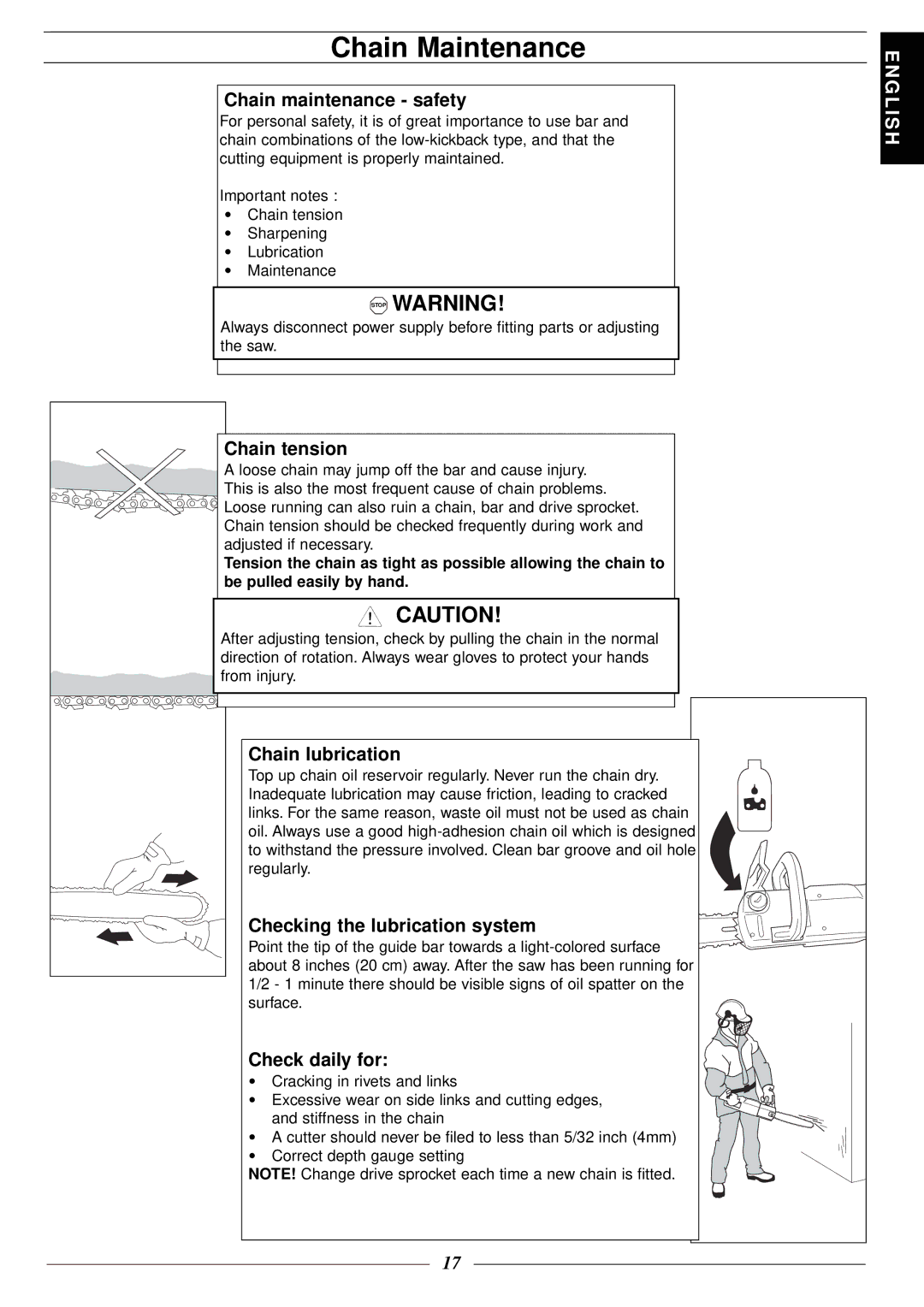

Chain tension

A loose chain may jump off the bar and cause injury. This is also the most frequent cause of chain problems. Loose running can also ruin a chain, bar and drive sprocket. Chain tension should be checked frequently during work and adjusted if necessary.

Tension the chain as tight as possible allowing the chain to be pulled easily by hand.

![]() CAUTION!

CAUTION!

After adjusting tension, check by pulling the chain in the normal direction of rotation. Always wear gloves to protect your hands from injury.

Chain lubrication

Top up chain oil reservoir regularly. Never run the chain dry. Inadequate lubrication may cause friction, leading to cracked links. For the same reason, waste oil must not be used as chain oil. Always use a good

Checking the lubrication system

Point the tip of the guide bar towards a

Check daily for:

• Cracking in rivets and links

• Excessive wear on side links and cutting edges, and stiffness in the chain

•A cutter should never be filed to less than 5/32 inch (4mm)

•Correct depth gauge setting

NOTE! Change drive sprocket each time a new chain is fitted.

ENGLISH

17