Chubby, Chubby LT specifications

The K2 Bike Chubby LT stands out as a versatile mountain bike designed for adventure enthusiasts seeking both performance and comfort on challenging terrains. This bike merges robust construction with innovative features to create an exceptional riding experience for both casual and seasoned riders.One of the defining characteristics of the K2 Bike Chubby LT is its lightweight yet durable aluminum frame. This frame is engineered to withstand the rigors of rocky trails and rugged paths while still being easy to maneuver. The bike's geometry is crafted for stability and control, allowing riders to confidently tackle steep climbs and descents alike.

The Chubby LT is equipped with a unique 4-inch fat tire system, which provides enhanced traction and stability. These oversized tires excel in various terrain conditions, from loose sand to muddy trails, ensuring that riders maintain a solid grip. The increased surface area also lends itself to a comfortable ride, effectively absorbing bumps and jolts encountered on uneven ground.

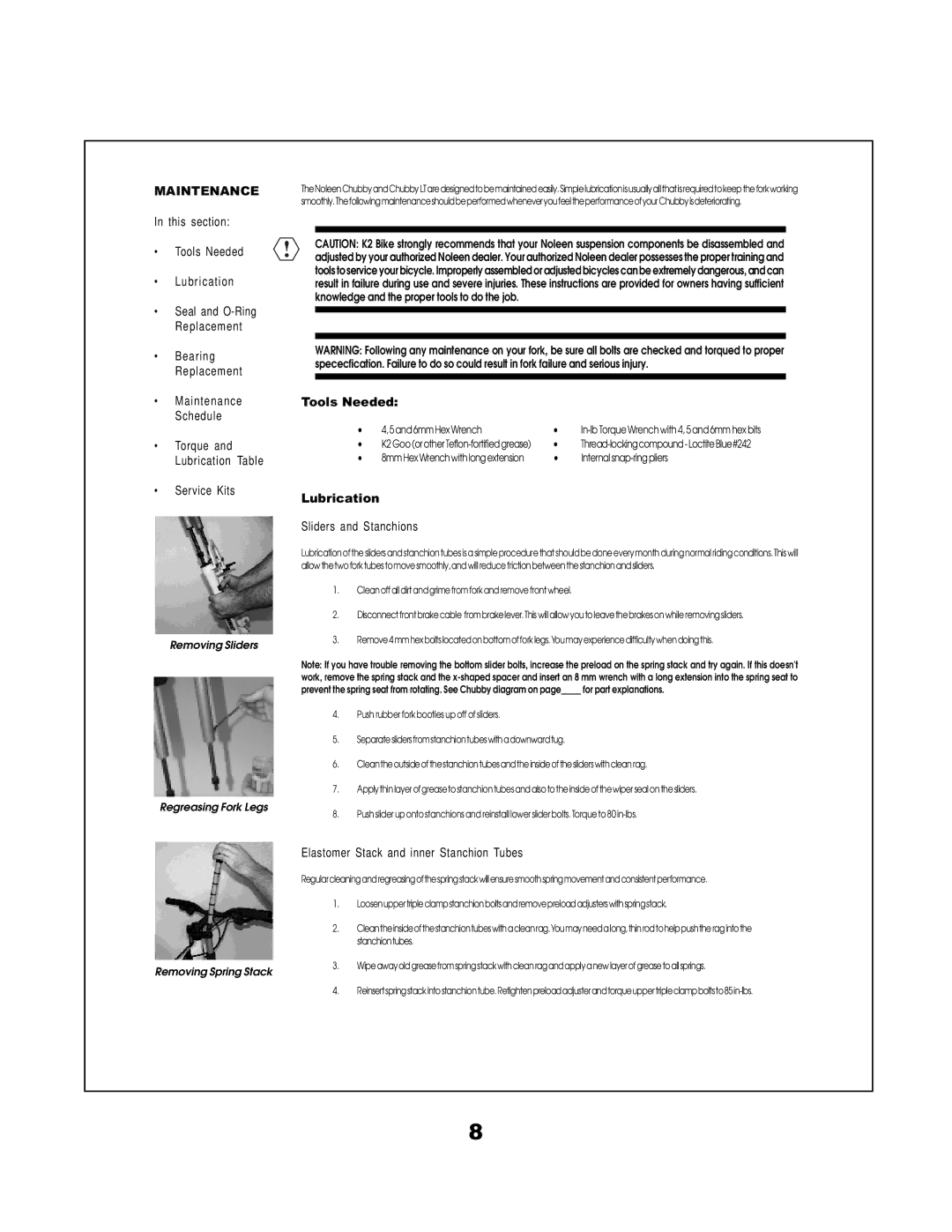

Another standout feature of the K2 Bike Chubby LT is its advanced suspension system. The bike features a front suspension fork designed to tackle obstacles without compromising control. This system absorbs impacts and provides responsiveness, allowing riders to glide smoothly over rough surfaces and maintain speed even on challenging descents.

In terms of gearing, the Chubby LT is equipped with a reliable 1x drivetrain, providing simplicity and ease of use. This setup allows for seamless shifting and offers a sufficient range of gears for tackling both steep climbs and flat sections, making it suitable for diverse riding conditions.

Additionally, the bike comes with powerful disc brakes, offering consistent and reliable stopping power in all weather conditions. This feature ensures enhanced safety, giving riders confidence when navigating downhills or challenging trails.

For added convenience, the K2 Bike Chubby LT features adjustable seats and ergonomic handlebars, allowing for a customized riding posture. This adaptability enhances comfort during long rides and promotes a natural riding position.

Overall, the K2 Bike Chubby LT is an impressive mountain bike that encapsulates the essence of outdoor adventure. With its combination of robust construction, innovative features, and rider-centric designs, it is well-equipped to handle the demands of any trail, making it an ideal choice for riders looking to explore the great outdoors.