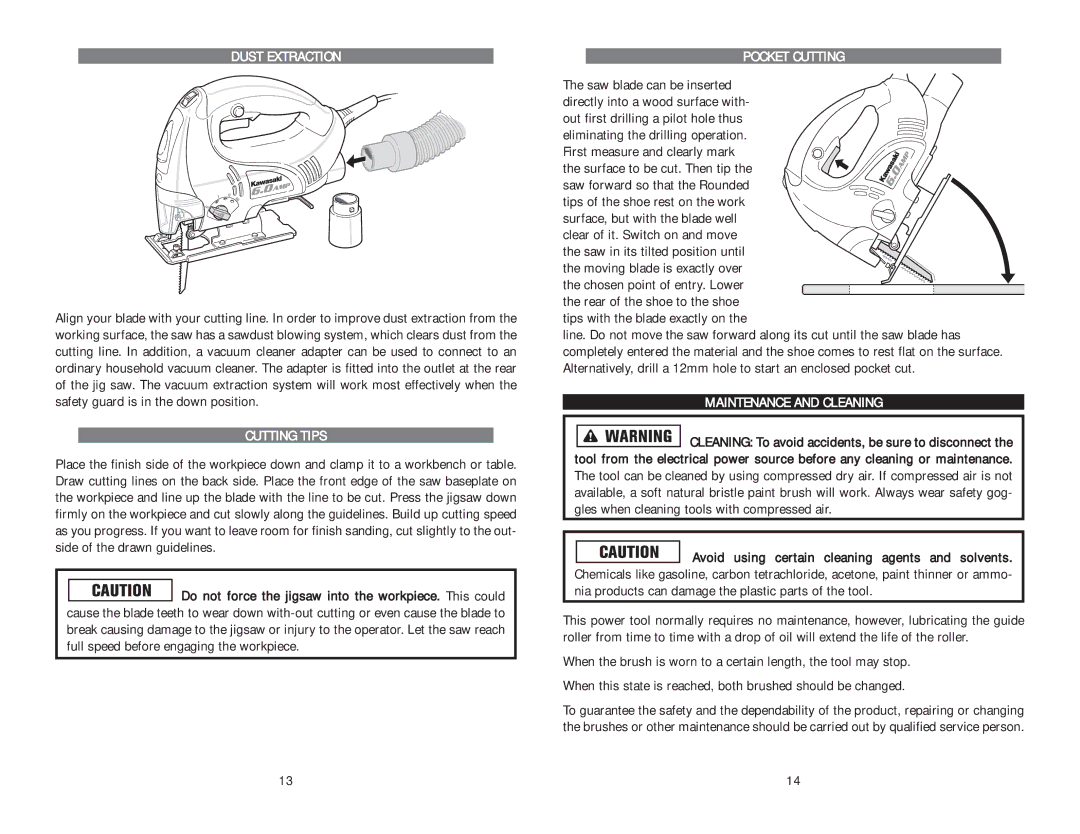

DUST EXTRACTION

Align your blade with your cutting line. In order to improve dust extraction from the working surface, the saw has a sawdust blowing system, which clears dust from the cutting line. In addition, a vacuum cleaner adapter can be used to connect to an ordinary household vacuum cleaner. The adapter is fitted into the outlet at the rear of the jig saw. The vacuum extraction system will work most effectively when the safety guard is in the down position.

CUTTING TIPS

Place the finish side of the workpiece down and clamp it to a workbench or table. Draw cutting lines on the back side. Place the front edge of the saw baseplate on the workpiece and line up the blade with the line to be cut. Press the jigsaw down firmly on the workpiece and cut slowly along the guidelines. Build up cutting speed as you progress. If you want to leave room for finish sanding, cut slightly to the out- side of the drawn guidelines.

![]()

![]()

![]()

![]()

![]()

![]() Do not force the jigsaw into the workpiece. This could cause the blade teeth to wear down

Do not force the jigsaw into the workpiece. This could cause the blade teeth to wear down

POCKET CUTTING

The saw blade can be inserted directly into a wood surface with-

out first drilling a pilot hole thus eliminating the drilling operation.

First measure and clearly mark the surface to be cut. Then tip the saw forward so that the Rounded tips of the shoe rest on the work

surface, but with the blade well clear of it. Switch on and move the saw in its tilted position until the moving blade is exactly over

the chosen point of entry. Lower the rear of the shoe to the shoe

tips with the blade exactly on the

line. Do not move the saw forward along its cut until the saw blade has completely entered the material and the shoe comes to rest flat on the surface. Alternatively, drill a 12mm hole to start an enclosed pocket cut.

MAINTENANCE AND CLEANING

![]()

![]()

![]()

![]()

![]()

![]()

![]() CLEANING: To avoid accidents, be sure to disconnect the tool from the electrical power source before any cleaning or maintenance. The tool can be cleaned by using compressed dry air. If compressed air is not available, a soft natural bristle paint brush will work. Always wear safety gog- gles when cleaning tools with compressed air.

CLEANING: To avoid accidents, be sure to disconnect the tool from the electrical power source before any cleaning or maintenance. The tool can be cleaned by using compressed dry air. If compressed air is not available, a soft natural bristle paint brush will work. Always wear safety gog- gles when cleaning tools with compressed air.

![]()

![]()

![]()

![]()

![]()

![]() Avoid using certain cleaning agents and solvents. Chemicals like gasoline, carbon tetrachloride, acetone, paint thinner or ammo- nia products can damage the plastic parts of the tool.

Avoid using certain cleaning agents and solvents. Chemicals like gasoline, carbon tetrachloride, acetone, paint thinner or ammo- nia products can damage the plastic parts of the tool.

This power tool normally requires no maintenance, however, lubricating the guide roller from time to time with a drop of oil will extend the life of the roller.

When the brush is worn to a certain length, the tool may stop.

When this state is reached, both brushed should be changed.

To guarantee the safety and the dependability of the product, repairing or changing the brushes or other maintenance should be carried out by qualified service person.

13 | 14 |