WELDING TIPS

•Make sure you move the torch across the weld at the proper speed. You want the weld metal to flow smoothly onto the work piece. If the bead is too high or too wide, your speed is too slow. If the bead is too narrow, your speed is too fast.

•If the

•If the

•If the joint is not filled on the first pass, continue making passes until the weld- ing joint is secure. Be sure to remove all remaining slag between passes.

•Never use an electric arc welder to thaw frozen pipes.

WELDING GUIDELINES

GENERAL

The KAWASAKI™ 90 Amp Wire Feed Welder incorporates a process called Flux Cored Arc Welding (FCAW). The FCAW process uses a special tubular wire with flux inside. When the current produced by the Welder flows through the circuit to the to the welding wire, an electrical arc is created between the wire and the work piece. Heat from the arc melts both the welding wire and the work piece. The liquefied metal then flows into the molten crater on the work piece creating a welded bond.

ARC WELDING BASICS

There are five general basics that can affect the output of the welded work piece: wire selection, heat setting, weld angle, wire speed, and travel speed.

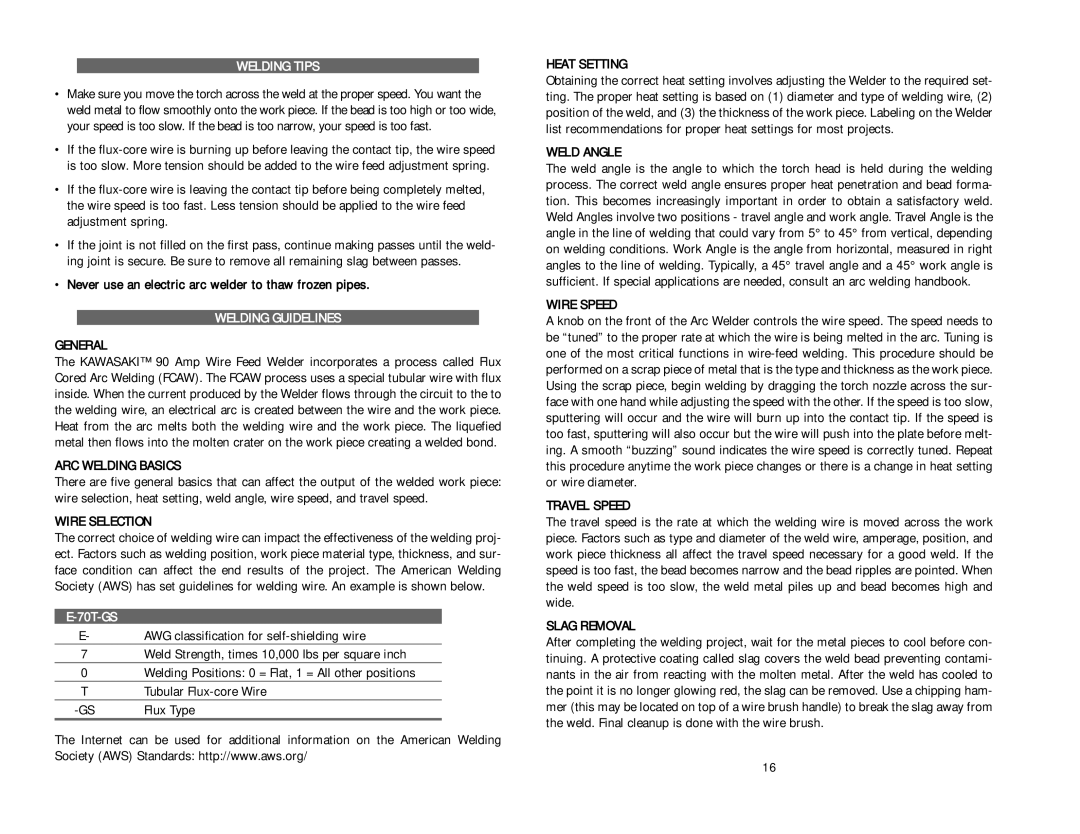

WIRE SELECTION

The correct choice of welding wire can impact the effectiveness of the welding proj- ect. Factors such as welding position, work piece material type, thickness, and sur- face condition can affect the end results of the project. The American Welding Society (AWS) has set guidelines for welding wire. An example is shown below.

|

|

E- | AWG classification for |

7 | Weld Strength, times 10,000 lbs per square inch |

0 | Welding Positions: 0 = Flat, 1 = All other positions |

T | Tubular |

Flux Type |

The Internet can be used for additional information on the American Welding Society (AWS) Standards: http://www.aws.org/

HEAT SETTING

Obtaining the correct heat setting involves adjusting the Welder to the required set- ting. The proper heat setting is based on (1) diameter and type of welding wire, (2) position of the weld, and (3) the thickness of the work piece. Labeling on the Welder list recommendations for proper heat settings for most projects.

WELD ANGLE

The weld angle is the angle to which the torch head is held during the welding process. The correct weld angle ensures proper heat penetration and bead forma- tion. This becomes increasingly important in order to obtain a satisfactory weld. Weld Angles involve two positions - travel angle and work angle. Travel Angle is the angle in the line of welding that could vary from 5° to 45° from vertical, depending on welding conditions. Work Angle is the angle from horizontal, measured in right angles to the line of welding. Typically, a 45° travel angle and a 45° work angle is sufficient. If special applications are needed, consult an arc welding handbook.

WIRE SPEED

A knob on the front of the Arc Welder controls the wire speed. The speed needs to be “tuned” to the proper rate at which the wire is being melted in the arc. Tuning is one of the most critical functions in

TRAVEL SPEED

The travel speed is the rate at which the welding wire is moved across the work piece. Factors such as type and diameter of the weld wire, amperage, position, and work piece thickness all affect the travel speed necessary for a good weld. If the speed is too fast, the bead becomes narrow and the bead ripples are pointed. When the weld speed is too slow, the weld metal piles up and bead becomes high and wide.

SLAG REMOVAL

After completing the welding project, wait for the metal pieces to cool before con- tinuing. A protective coating called slag covers the weld bead preventing contami- nants in the air from reacting with the molten metal. After the weld has cooled to the point it is no longer glowing red, the slag can be removed. Use a chipping ham- mer (this may be located on top of a wire brush handle) to break the slag away from the weld. Final cleanup is done with the wire brush.

16