ACE technology

The laws of physics dictate that to get good bass extension out of a loudspeaker you need a large enclosure volume, and to get high output levels you need to move a lot of air. This is why the more expensive loudspeaker systems have large or multiple bass drivers and big enclosures. Many potential solutions to the enclosure size problem have been tried over the years, but KEF’s ACE technology is the one which genuinely works and is useable in production systems.

ACE stands for Acoustic Compliance Enhancement. Granules of activated carbon are packed into porous fabric tubes and fitted inside the loudspeaker enclosure. These carbon granules are highly porous with many pores, macropores and micropores giving them an incredibly high surface area. ACE works by

a process called ‘adsorption’. It’s a physical process whereby the granules of activated carbon continually work to reduce the acoustic pressure within

an enclosure. When the drive unit cone moves inwards the air pressure inside the enclosure increases. This triggers the carbon granules to pull air molecules onto the

surface of the material by the weak, gravity type, Van de Waals force.

This has the effect of reducing the overall air pressure inside the enclosure. When the cone moves out, and acts to expand the air inside the enclosure and reduce its pressure, the granules ‘give out’ air molecules, again reducing the pressure change. A smaller change in the internal enclosure pressure is equivalent to

having a larger enclosure volume. So by placing modules of activated carbon granules inside the enclosure we are getting the acoustic performance of an enclosure with a much larger

physical volume.

The adsorption process is linear and reversible, there is no distortion introduced because of the operation of the carbon granules. In fact, the bass quality of ACE loaded enclosures is consistently admired by audiophiles for its clarity and detail.

Room Correction

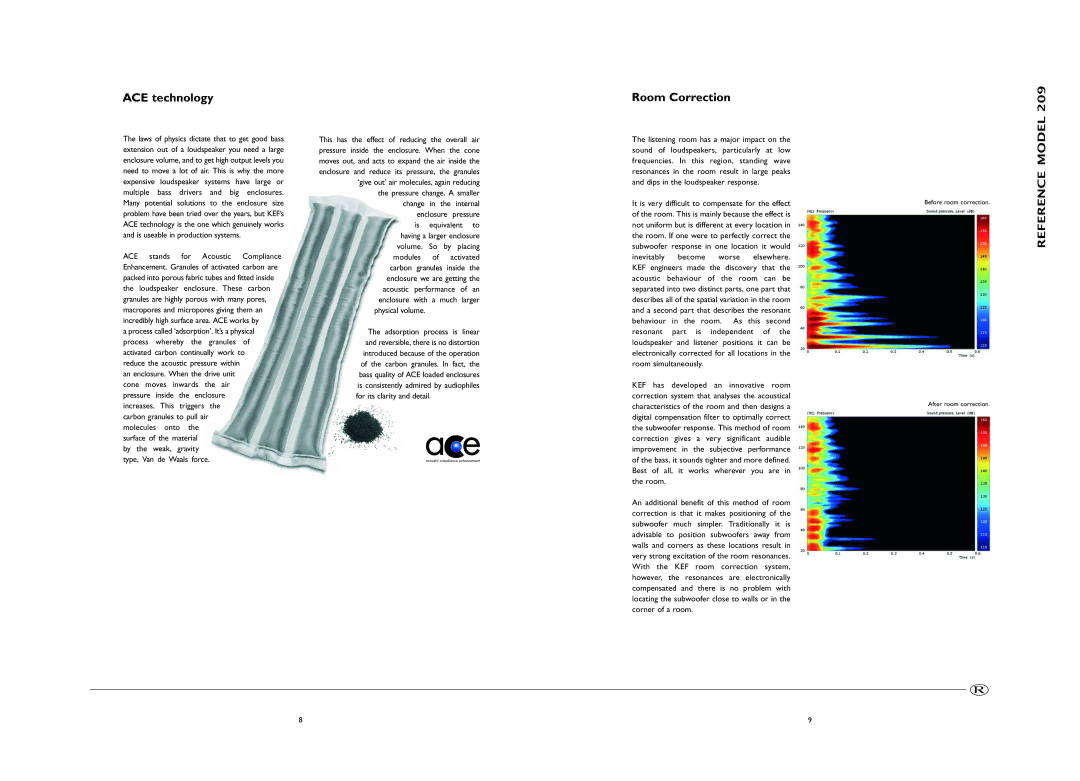

The listening room has a major impact on the sound of loudspeakers, particularly at low frequencies. In this region, standing wave resonances in the room result in large peaks and dips in the loudspeaker response.

It is very difficult to compensate for the effect of the room. This is mainly because the effect is not uniform but is different at every location in the room. If one were to perfectly correct the subwoofer response in one location it would inevitably become worse elsewhere. KEF engineers made the discovery that the acoustic behaviour of the room can be separated into two distinct parts, one part that describes all of the spatial variation in the room and a second part that describes the resonant behaviour in the room. As this second resonant part is independent of the loudspeaker and listener positions it can be electronically corrected for all locations in the room simultaneously.

KEF has developed an innovative room correction system that analyses the acoustical characteristics of the room and then designs a digital compensation filter to optimally correct the subwoofer response. This method of room correction gives a very significant audible improvement in the subjective performance of the bass, it sounds tighter and more defined. Best of all, it works wherever you are in the room.

An additional benefit of this method of room correction is that it makes positioning of the subwoofer much simpler. Traditionally it is advisable to position subwoofers away from walls and corners as these locations result in very strong excitation of the room resonances. With the KEF room correction system, however, the resonances are electronically compensated and there is no problem with locating the subwoofer close to walls or in the corner of a room.

Before room correction.

After room correction.

8 | 9 |