| NEEDLE AND THREAD | TABLE |

THREAD S}ZE | NEEDLEI | FABRfC |

I slz!_j |

| |

|

|

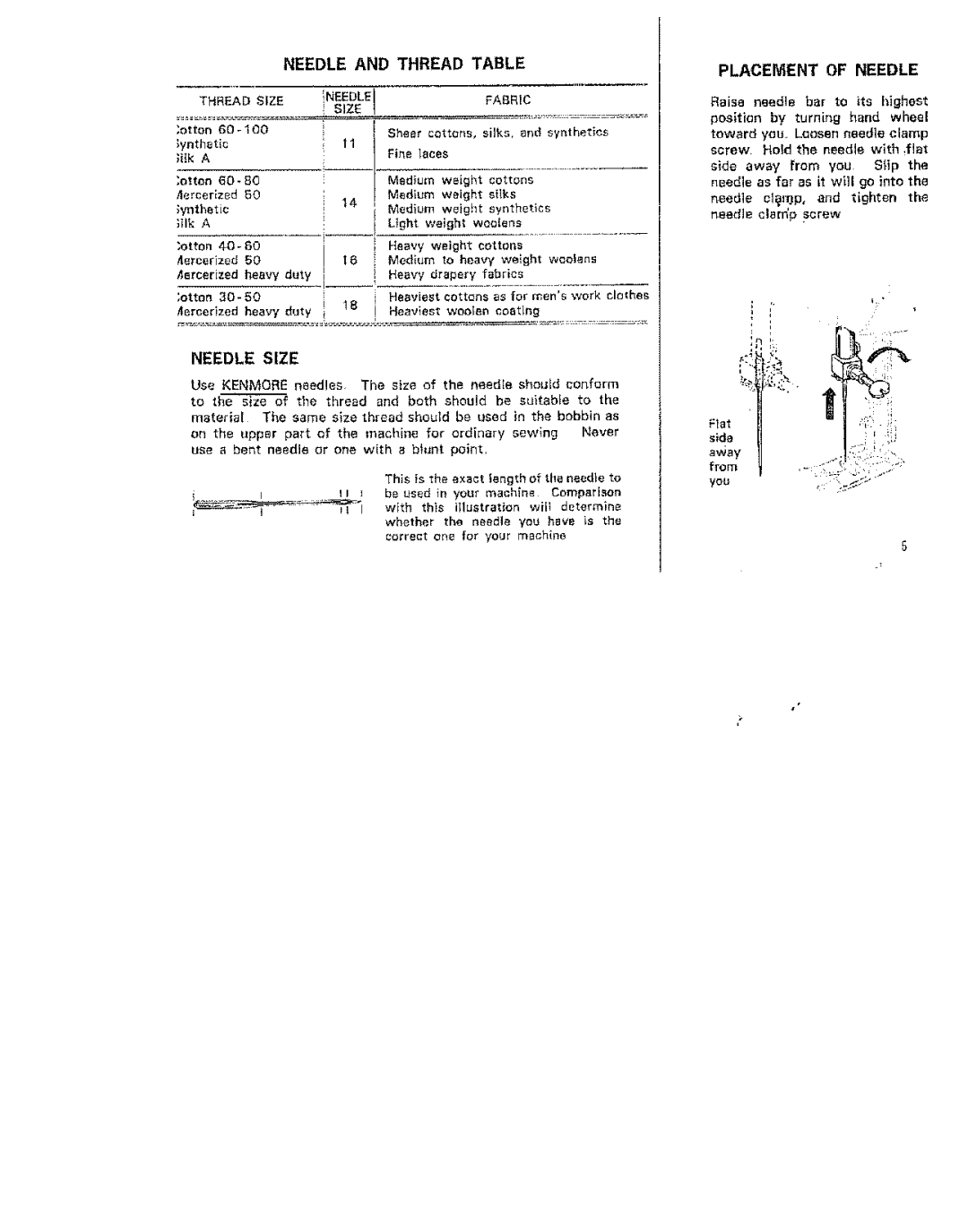

PLACEMENT OF NEEDLE

Raise needle bar to its highest position by turning hand wheel

;otton 60 - 1 O0

;ynthetic ;_lk A

:otton 60- 80 _lercerized 50

;ynthetic ;ilk A

"otton 40-60 4ercerized 50

t4

Sheer cottons, silks, and synthetics

Fine laces

Medium weight cottons

Medium weight silks

Medium weight synthetics

Light weight woolens

Heavy weight cottons

Medium to heavy weight woolens

toward you, Loosen needle clamp screw, Hold the needle with ,fiat

s_de away from you, Stip the needle as far as it will go into the needle clarop, and tighten the needle clam'p screw

/tercerized heavy duty

:otton 30- 50 /tercerized heavy duty

16 Heavy drapery fabrics

Heaviest cottons as for men's work clothes

18 Heaviest woolen coating

NEEDLE | SIZE |

|

|

|

|

|

|

|

|

|

|

| |||

Use | KENMORE | needles, | The | size of | the needle | should |

| conform | |||||||

to | t_ | size | of | the |

| thread | and | both | should | be | suitable | to | the | ||

material |

| The | same | size | thread | shoutd | be | used | in the | bobbin | as | ||||

on | the | upper | part | of | the | machine | for | ordinary | sewing |

| Never | ||||

use | a | bent | needle | or | one with | a | b_unt point, |

|

|

|

| ||||

|

|

|

|

|

|

|

| This is the exact length of the needle to | |||||||

|

|

|

|

|

|

|

| be used in your | machine | Comparison | |||||

|

|

|

|

|

|

|

| with | this | illustration | will |

| determine | ||

|

|

|

|

|

|

|

| whether | the needte you have is the | ||||||

|

|

|

|

|

|

|

| correct one for your machine |

|

| |||||

£

Flat

sidei

away from

you,

5

p